Chapter: Mechanical : Manufacturing Technology : CNC Machines

Water Machining

Water Machining

A water

jet cutter, also known as a waterjet or waterjet, is an industrial tool capable

of cutting a wide variety of materials using a very high-pressure jet of water,

or a mixture of water and an abrasive substance. The term abrasive jet refers

specifically to the use of a mixture of water and abrasive to cut hard

materials such as metal or granite, while the terms pure waterjet and

water-only cutting refer to waterjet cutting without the use of added

abrasives, often used for softer materials such as wood or rubber. Waterjet

cutting is often used during fabrication of machine parts. It is the preferred

method when the materials being cut are sensitive to the high temperatures

generated by other methods. Waterjet cutting is used in various industries,

including mining andaerospace, for cutting, shaping, and reaming.

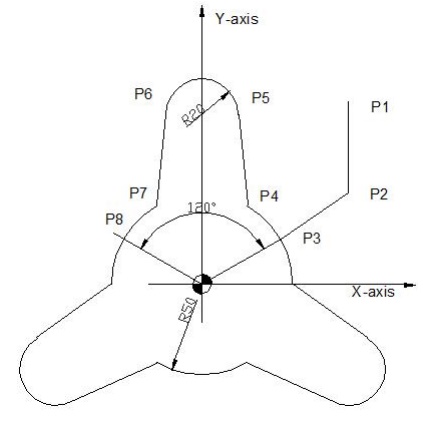

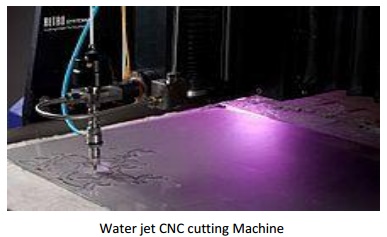

Water jet CNC

cutting Machine

While using high-pressure water

for erosion dates back as far as the mid-1800s with hydraulic mining, it was

not until the 1930s that narrow jets of water started to appear as an

industrial cutting device. In 1933, the Paper Patents Company in Wisconsin

developed a paper metering, cutting, and reeling machine that used a diagonally

moving waterjet nozzle to cut a horizontally moving sheet of continuous paper.

These early applications were at a low pressure and restricted to soft

materials like paper.

Waterjet technology evolved in

the post-war era as researchers around the world searched for new methods of

efficient cutting systems. In 1956, Carl Johnson of Durox International in

Luxembourg developed a method for cutting plastic shapes using a thin stream

high-pressure waterjet, but those materials, like paper, were soft materials.[3]

In 1958, Billie Schwacha of North American Aviation developed a system using

ultra-high-pressure liquid to cut hard materials.[4] This system

used a 100,000 psi (690 MPa) pump to deliver ahypersonic liquid jet that could

cut high strength alloys such as PH15-7-MO stainless steel. Used as a honeycomb

laminate on the Mach 3 North American XB-70 Valkyrie, this cutting method

resulted in delaminating at high speed, requiring changes to the manufacturing

process. While not effective for the XB-70 project, the concept was valid and

further research continued to evolve waterjet cutting. In 1962, Philip Rice of

Union Carbideexplored using a pulsing waterjet at up to 50,000 psi (345 MPa) to

cut metals, stone, and other materials. Research by S.J. Leach and G.L. Walker

in the mid-1960s expanded on traditional coal waterjet cutting to determine

ideal nozzle shape for high-pressure waterjet cutting of stone, and Norman

Franz in the late 1960s focused on waterjet cutting of soft materials by

dissolving long chain polymers in the water to improve the cohesiveness of the

jet stream. In the early 1970s, the desire to improve the durability of the

waterjet nozzle led Ray Chadwick, Michael Kurko, and Joseph Corriveau of the

Bendix Corporation to come up with the idea of using corundum crystal to form a

waterjet orifice, while Norman Franz expanded on this and created a waterjet

nozzle with an orifice as small as 0.002 inches (0.05 mm) that operated at

pressures up to 70,000 psi (483 MPa). John Olsen, along with George Hurlburt

and Louis Kapcsandy at Flow Research (later Flow Industries), further improved

the commercial potential of the waterjet by showing that treating the water

beforehand could increase the operational life of the nozzle.

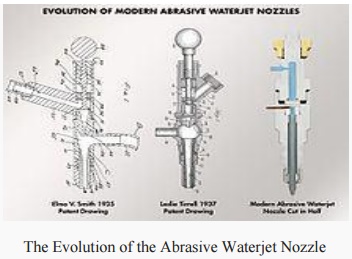

Abrasive

waterjet

The Evolution of the Abrasive Waterjet Nozzle

While cutting with water is

possible for soft materials, the addition of an abrasive turned the waterjet

into a modern machining tool for all materials. This began in 1935 when the

idea of

adding an abrasive to the water

stream was developed by Elmo Smith for the liquid abrasive blasting.

Smith’s design was further refined by Leslie Tirrell of the Hydroblast

Corporation

in 1937, resulting in a nozzle

design that created a mix of high-pressure water and abrasive for the purpose

of wet blasting. Producing a commercially viable abrasive waterjet nozzle for

precision cutting came next by Dr. Mohamed Hashish who invented and led an

engineering research team at Flow Industries to develop the modern abrasive

waterjet cutting technology. Dr. Hashish, who also coined the new term

"Abrasive Waterjet" AWJ, and his team continued to develop and

improve the AWJ technology and its hardware for many applications which is now

in over 50 industries worldwide. A most critical development was creating a durable

mixing tube that could withstand the power of the high-pressure AWJ, and it was

Boride Products (now Kennametal) development of their ROCTEC line of ceramic

tungsten carbide composite tubes that significantly increased the operational

life of the AWJ nozzle. Current work on AWJ nozzles is on micro abrasive

waterjet so cutting with jets smaller than 0.015 inch in diameter can be

commercialized.

Applications

Because the nature

of the cutting stream can be easily modified the water jet can be used in

nearly every industry; there are many different materials that the water jet

can cut. Some of them have unique characteristics that require special

attention when cutting.

Materials commonly cut with a water jet include rubber, foam, plastics, leather, composites, stone, tile, metals, food, paper and much more. Materials that cannot be cut with a water jet are tempered glass, diamonds and certain ceramics. Water is capable of cutting materials over eighteen inches (45 cm) thick.

Related Topics