Chapter: Mechanical and Electrical : Thermal Engineering : Air Compressors

Volumetric efficiency of compressor

VOLUMETRIC EFFICIENCY:

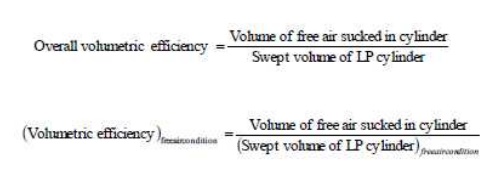

Volumetric efficiency of compressor is the measure of the deviation from volume handling capacity of compressor. Mathematically, the volumetric efficiency is given by the ratio of actual volume of air sucked and swept volume of cylinder. Ideally the volume of air sucked should be equal to the swept volume of cylinder, but it is not so in actual case. Practically the volumetric efficiency lies between 60 to 90%. Volumetric efficiency can be overall volumetric efficiency and absolute volumetric efficiency as given below.

Here free air condition refers to the standard conditions. Free air condition may be taken as 1 atm or 1.01325 bar and 15oC or 288K. consideration for free air is necessary as otherwise the different compressors can not be compared using volumetric efficiency because specific volume or density of air varies with altitude. It may be seen that a compressor at datum level (sea level) shall deliver large mass than the same compressor at high altitude. This concept is used for giving the capacity of compressor in terms of „free air

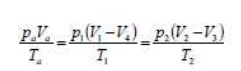

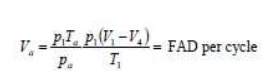

delivery‟(FAD). “Free air delivery is the volume of air delivered being reduced to free air conditions”. In case of air the free air delivery can be obtained using perfect gas equation as,

Where subscript a or pa, Va, Ta denote properties at free air conditions

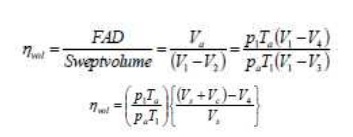

This volume Va gives „free air delivered‟per cycle by the compressor. Absolute volumetric efficiency can be defined, using NTP conditions in place of free air conditions.

Here Vs is the swept volume = V1 – V3 and Vc is the clearance volume = V3

Volumetric efficiency depends on ambient pressure and temperature, suction pressure and temperature, ratio of clearance to swept volume, and pressure limits. Volumetric efficiency increases with decrease in pressure ratio in compressor.

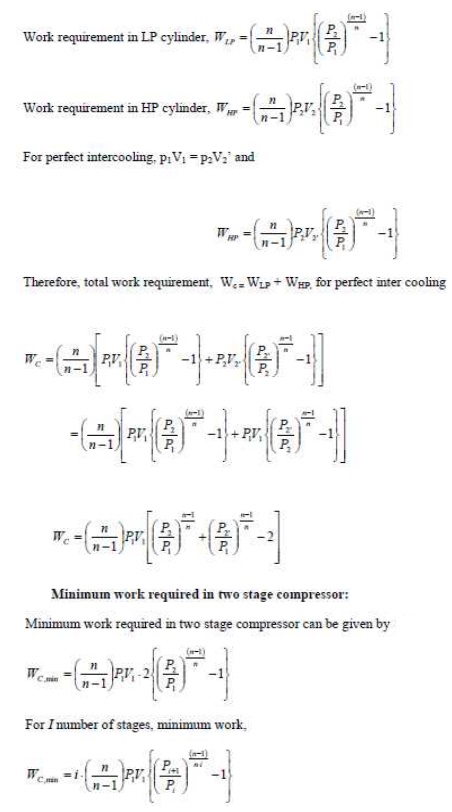

Mathematical analysis of multistage compressor is done with following assumptions:

(i) Compression in all the stages is done following same index of compression and there is no pressure drop in suction and delivery pressures in each stage. Suction and delivery pressure remains constant in the stages.

(ii) There is perfect inter cooling between compression

stages.

(iii) Mass handled in different stages is same i.e., mass of air in LP and HP stages are same. (iv) Air behaves as perfect gas during compression.

From combined p-V diagram the compressor work requirement can be given as,

Related Topics