Chapter: Mechanical and Electrical : Thermal Engineering : Air Compressors

Air Compressors

AIR COMPRESSORS

PREREQUISITE DISCUSSION

A history associated with air compressors like a

device goes back in order to antiquity.

Guy offers utilized

compressors data compression with regard to a large number of many years in

order to warmth their house, prepare meals, as well as proceed items. The first

kind of compressor had been the bellows accustomed to great time compacted compressors

on to the fireplace. These types of easy compressing models had been possibly

driven through guy or even creatures in order to shrink. They were changed

through mechanized air compressors that have been employed for commercial

reasons. Along with improvements within technology, compressors had been

decreased in dimensions as well as discovered utilizes beyond industrial

facilities because helps with regard to marine scuba diving in order to energy

pneumatic resources as well as exercises.

CONCEPT OF AIR COMPRESSOR

Introduction:

Ø The

process of increasing the pressure of air, gas or vapour by reducing its volume

is what compression.

Ø The

devise used to carry out this process is called a compressor.

Principles on which compressors work:

Ø A compressor

is a mechanical device that increases the pressure of a gas by

reducing its volume.

Ø Compressor

is a machine which increases the pressure of a fluid by mechanically decreasing

its volume (i.e. by compressing it).(The fluid here is generally air since

liquids are theoretically incompressible).

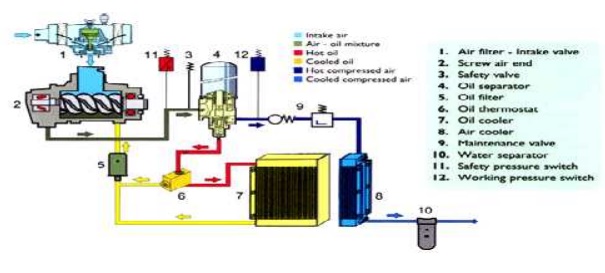

Construction:

SIGNIFICANCE OF AIR COMPRESSORS

Ø Compressed

Air is often described as the fourth utility, although not as ubiquitous as electricity, petrol and gas,

it plays a fundamental part in the modern world.

Ø The

importance of compressed air is often over looked, but in reality it plays a

vital part in most modern manufacturing processes and modern civilization.

Ø Although

we may not realize it most products we use today could simply not be made

without compressed air.

Ø Compressed

air accounts for about 10% of the global energy used in industry today.

Ø With so

many applications in different environments being dependant on compressed air,

the compressors not only have to compress the air to a specific pressure, at a

certain flow, it has to deliver air of the right quality.

Ø To most

people, a compressor is all that is required to compress air, but to obtain the

right quality of the compressed air, more equipment is often needed.

Ø Filters

and dryers are often needed to remove oil and water before it reaches the

application.

Ø Compressed

Air has a range of completely oil-less compressors where air comes into contact

with the process it serves and so the quality is critical, for example in where

a compressor may be used in a food packaging role.

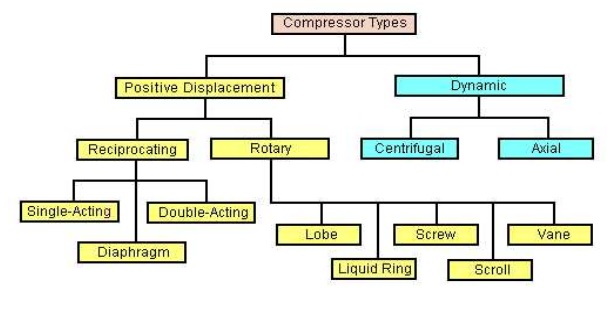

CLASSIFICATION OF AIR COMPRESSORS

Types of compressors

Positive displacement compressor

Ø In the

positive-displacement type, a given quantity of air or gas is trapped in a

compression chamber and the volume it occupies is mechanically reduced, causing

a corresponding rise in pressure prior to discharge.

Ø At

constant speed, the air flow remains essentially constant with variations in

discharge pressure.

Ø Ex:

Reciprocating compressors, vane

compressors & so on.

Dynamic compressors:

Ø Dynamic

compressors impart velocity energy to continuously flowing air or gas by means

of impellers rotating at very high speeds.

Ø The

velocity energy is changed into pressure energy both by the impellers and the

discharge volutes or diffusers.

Ø In the

centrifugal-type dynamic compressors, the shape of the impeller blades

determines the relationship between air flow and the pressure (or head)

generate.

Ø Ex:

centrifugal compressors, axial compressors.

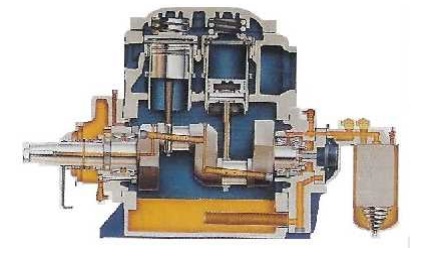

Reciprocating compressors

Ø In a

reciprocating compressor, a volume of gas is drawn into a cylinder; it is

trapped and compressed by piston, then discharged into the discharge line.

Ø The

cylinder valves control the flow of gas through the cylinder; these valves act

as check valves.

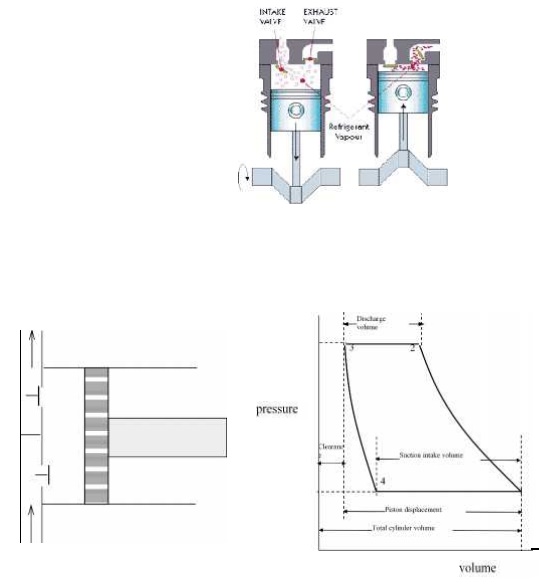

Principle

of Operation

Ø The

piston is driven by a crank shaft via a connecting rod.

Ø At the

top of the cylinder are a suction valve and a discharge valve.

Ø A

reciprocating compres sor usually has two, three, four, or six cylinders in it.

Ø The

suction valve opens at point 4.

Ø As the

piston travels toward the bottom dead center, the volume of the c ylinder

increases and the vapor flows into the cylinder.

Ø The

pressure inside the cylinder is slightly less than suction line pressu re. The

pressure difference pushes the val ve open on during the suction stroke.

Ø At point

2, the pressure inside the cylinder has become slightly greater than discharge

line pressure.

Ø This

causes the valve opening allowing the gas to flow out of the cylinder.

Ø The

volume continues to decrease toward point 3, maintaining a sufficient pressure

difference across the discharge valve to hold it open.

Ø At point

3, the piston reaches the top dead center and reverses direction.

Ø At top

dead center, as the piston comes to a complete stop prior to reversing

direction, the pressure across the valve is equal.

Ø So, the

discharge valve is closed.

Ø As the

piston moves towards point 4, the volume increases and the pressure decreases

in the cylinder.

Ø The gas

trapped in the cylinder expands as the volume increases until to point 4.

Ø At point

4, the gas pressure inside the cylinder becomes less than the suction line

pressure, so the suction valve opens again.

Ø The cycle

then starts over again.

Ø The shape

of the re-expansion line (Line 3-4) is dependent on the same compression

exponent that determines the shape of the compression line.

What is the difference between a

single and two stage compressor?

Ø The simplest way to explain the difference between a single

stage compressor and dual or two stage compressor is the number of times that

the air is compressed. In a single stage system the air is compressed once and

in a dual stage the air is compressed twice.

Ø In a single stage piston compressor the air is drawn into a

cylinder and compressed in a single piston stoke to a pressure of approximately

120 PSI. Then it is send to the storage tank. All rotary compressors are single

stage.

Ø In a dual stage compressor the first step is the same except

that the air is not directed to the storage tank, the air is sent via an inter

cooler tube to a second, smaller high pressure piston and compressed a second

time and compressed to a pressure of 175 PSI. Then it is sent through the after

cooler to the storage tank.

Ø In a dual stage pump the first stage cylinder is always a larger

diameter. Also a dual stage pump will always have an inter cooler tube or

finned housing attached to the pump to cool the air before being compressed a

second time.

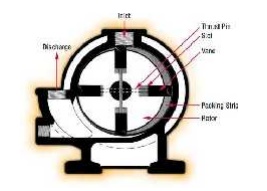

ROTARY VANE COMPRESSORS

Rotary

vane compressors consist of a rotor with a number of blades

inserted in radial slots in the rotor.

Ø The rotor is mounted offset in a larger housing that is either

circular or a more complex shape. As

the rotor turns, blades slide in and out of the slots keeping contact with the

outer wall of the housing. Thus, a series of decreasing volumes is created by

the rotating blades.

MULTISTAGE COMPRESSION:

Multistage

compression refers to the compression process completed in more than one stage

i.e., a part of compression occurs in one cylinder and subsequently compressed

air is sent to subsequent cylinders for further compression. In case it is

desired to increase the compression ratio of compressor then multi-stage

compression becomes inevitable. If we look at the expression for volumetric

efficiency then it shows that the volumetric efficiency decreases with increase

in pressure ratio. This aspect can also be explained using p-V representation

shown in Figure.

A

multi-stage compressor is one in which there are several cylinders of different

diameters. The intake of air in the first stage gets compressed and then it is

passed over a cooler to achieve a temperature very close to ambient air. This

cooled air is passed to the intermediate stage where it is again getting

compressed and heated. This air is again passed over a cooler to achieve a

temperature as close to ambient as possible. Then this compressed air is passed

to the final or the third stage of the air compressor where it is compressed to

the required pressure and delivered to the air receiver after cooling

sufficiently in an after-cooler.

Advantages

of Multi-stage compression:

The work done in compressing the air is reduced, thus power

can be saved

2. Prevents mechanical problems as the air temperature is

controlled

3. The suction and delivery valves remain in cleaner condition

as the temperature and vaporization of lubricating oil is less

4. The

machine is smaller and better balanced

5. Effects

from moisture can be handled better, by draining at each stage

6.

Compression approaches near isothermal

7. Compression

ratio at each stage is lower when compared to a single-stage machine

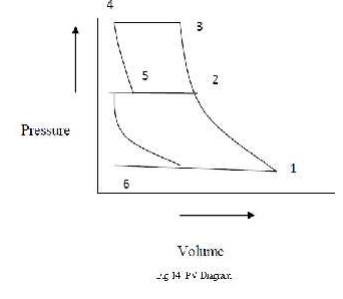

WORK DONE IN A SINGLE STAGE

RECIPROCATING COMPRESSOR WITH CLEARANCE VOLUME:

Considering clearance volume: With clearance volume the cycle

is represented on Figure. The work done for compression of air polytropically

can be given by the are a enclosed in cycle 1-2-

3-4.

Clearance volume in compressors varies from 1.5% to 35% depending upon type of

compressor.

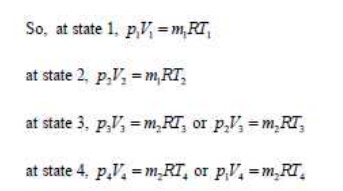

In the

cylinder of reciprocating compressor (V1-V4) shall be the actual volume of air

delivered per cycle. Vd = V1 – V4. This (V1 – V4) is

actually the volume of air in hated in the cycle and delivered subsequently.

If air is

considered to behave as perfect gas then pressure, temperature, volume and mass

can be inter related using perfect gas equation. The mass at state 1 may be

given as m1 mass at state 2 shall be m1, but at state 3 after delivery mass

reduces to m2 and at state 4 it shall be m2.

Ideally

there shall be no change in temperature during suction and delivery i.e., T4 =

T1 and T2 = T3 from earlier equation

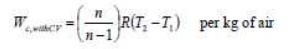

Thus

(m1-m2) denotes the mass of air sucked or delivered. For unit mass of air

delivered the work done per kg of air can be given as,

Thus from above expressions it is

obvious that the clearance volume reduces the effective swept volume i.e., the

mass of air handled but the work done per kg of air delivered remains

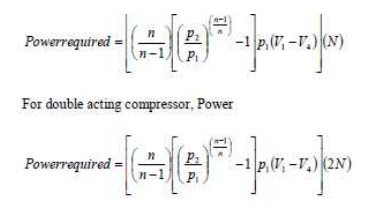

unaffected. From the cycle work estimated as above the theoretical power required

for running compressor shall be,

For

single acting compressor running with N rpm, power input required, assuming

clearance volume.

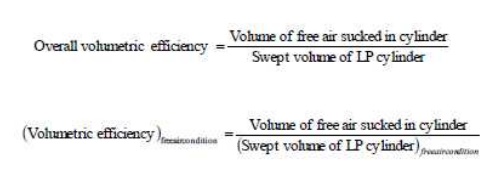

VOLUMETRIC EFFICIENCY:

Volumetric

efficiency of compressor is the measure of the deviation from volume handling

capacity of compressor. Mathematically, the volumetric efficiency is given by

the ratio of actual volume of air sucked and swept volume of cylinder. Ideally

the volume of air sucked should be equal to the swept volume of cylinder, but it

is not so in actual case. Practically the volumetric efficiency lies between 60

to 90%. Volumetric efficiency can be overall volumetric efficiency and absolute

volumetric efficiency as given below.

Here free air condition refers to the standard

conditions. Free air condition may be taken as 1 atm or 1.01325 bar and 15oC or

288K. consideration for free air is necessary as otherwise the different

compressors can not be compared using volumetric efficiency because specific

volume or density of air varies with altitude. It may be seen that a compressor

at datum level (sea level) shall deliver large mass than the same compressor at

high altitude. This concept is used for giving the capacity of compressor in

terms of „free air

delivery‟(FAD). “Free air

delivery is the volume of air delivered being reduced to free air conditions”. In case

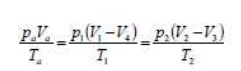

of air the free air delivery can be obtained using perfect gas equation as,

Where subscript a or pa, Va, Ta denote properties at free air

conditions

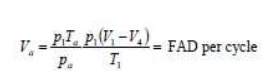

This volume Va gives „free air

delivered‟per cycle by the compressor. Absolute

volumetric efficiency can be defined, using NTP conditions in place of free air

conditions.

Here Vs is the swept volume = V1 – V3 and

Vc is the clearance volume = V3

Volumetric efficiency depends on

ambient pressure and temperature, suction pressure and temperature, ratio of

clearance to swept volume, and pressure limits. Volumetric efficiency increases

with decrease in pressure ratio in compressor.

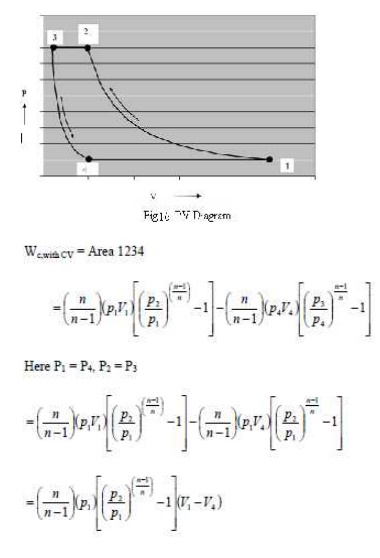

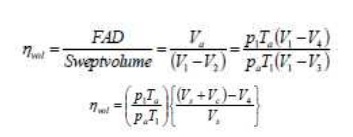

Mathematical analysis of multistage compressor is

done with following assumptions:

(i) Compression

in all the stages is done following same index of compression and there is no

pressure drop in suction and delivery pressures in each stage. Suction and

delivery pressure remains constant in the stages.

(ii) There

is perfect inter

cooling between compression

stages.

(iii) Mass handled in different

stages is same i.e., mass of air in LP and HP stages are same. (iv) Air behaves

as perfect gas during compression.

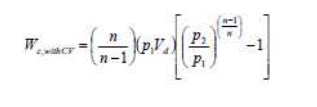

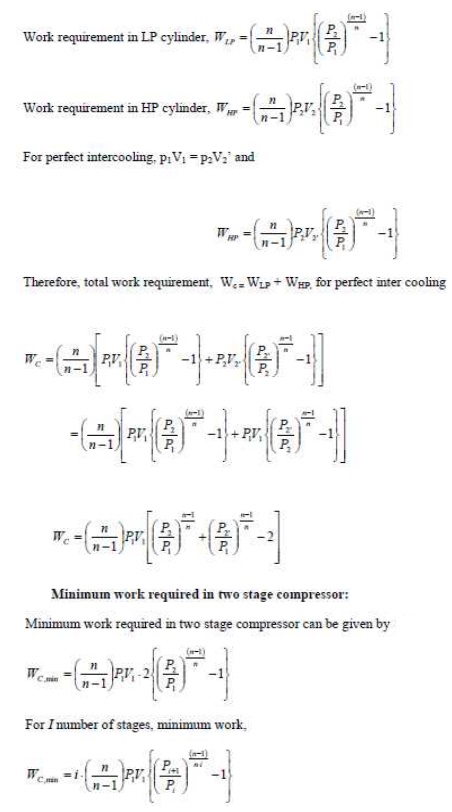

From combined p-V diagram the compressor work requirement can

be given as,

APPLICATION OF COMPRESSORS

Ø Reciprocating

compressors are typically used where high compression ratios (ratio of

discharge to suction pressures) are required per stage without high flow rates,

and the process fluid is relatively dry.

Ø Screw

compressors: Trailer mounted diesel powered units are often seen at

construction sites, and are used to power air operated construction machinery.

Ø P.E.T

bottling industries, gas filling stations usually use reciprocating

compressors.

Ø Processing

equipment, Oxygen Generators Oil Atomization use compressors of required

capacity.

Ø Air

compressors: a compressor that takes in air at atmospheric pressure and

delivers it at a higher pressure.

Ø Compressors

serve the basic necessities & form an integral part of the company .

Ø Pneumatic

brakes

Ø Pneumatic

drills

Ø Pneumatic

jacks

Ø Pneumatic

lifts

Ø Spray

painting

Ø Shop

cleaning

Ø Injecting

fuel in Diesel engines

Ø Refrigeration

and Air conditioning systems.

Related Topics