Chapter: Basic Concept of Biotechnology : Plant Molecular Farming: A Promising Stratergy in Biotechnology

Use of non-chromatographic methods

Use of

non-chromatographic methods

Mostly

the non-chromatographic method involves capturing and partial purifying of

oleosin-fusion proteins by centrifugation (Van Rooijenand Moloney, 1995).

These fusions have oleosin proteins as N-terminal fusion partners that allow in vivo targeting and/or post-extraction

capture of the target protein on the surface of oil bodies (Boothe et al.,2010).

Purification of oil bodies with attached fusions is done by several washing

steps in aqueous solutions using centrifugation. Attached recombinant protein

can be released from oil bodies by proteolytic cleavage of the oleosin-target

protein linkage or by elution in the case of affinity bound proteins. The

affinity binding approach is exemplified by constructs developed recently that

contain an N-terminal anti-oleosin single chain antibody (scFv) as the fusion

partner. Following their elution from oil bodies these fusions can be cleaved

either chemically (e.g. acidic cleavage) or enzymatically to release the

recombinant protein ( Bootheet al., 2010 and

Nykiforuk et al.,

2011). The potential downside of these two strategies is

the need to cleave the recombinant protein from the oleosin or scFv fusion

partner. The cleavage precision and efficiency,whether chemical or enzymatic,

is typically less than 70% and results in reduced product yield. Subsequent

purification of released recombinant proteins from respective fusions is done

by standard adsorption chromatography. Other equally good examples of

non-chromatographic purification methods utilized unique protein properties

(size, hydrophobicity or stability) and host system properties to accomplish

enhanced separation efficiency. Lee and Forciniti

(2010) explored the use of aqueous two-phase (PEG/salt)

partitioning as a sole recovery and purification method of non-glycosylated mAb

expressed in corn seed. By manipulating the system composition, pH, and ionic

strength they managed to partially purify the antibody in a three-stage

process. The first two stages were typical two-phase partitioning with the

target protein concentration enriched in the bottom (aqueous salt phase) and

host impurities in the top (PEG) phase. These two-extraction protocols resulted

in a rather modest mAb purification of 1.3- and 1.4-fold, respectively. The

third stage consisted of mAb precipitation at the two-phase interface and

resulted in almost 10-fold purification. Overall, the three-stage processes

delivered 72% pure mAb with 49% yield. Clearly, an additional adsorption step,

most likely affinity chromatography, would be needed to purify the antibody for

biopharmaceutical applications. Aspelund and Glatz

(2010) demonstrated purification of recombinant collagen

from low pH corn extracts by cross-flow filtration. Diafiltration of corn

endosperm extracts at pH 3.1 by using 100-kDa MWCO membranes removed 96% of

host protein and resulted in 89% pure collagen. Improved purification of

collagen was achieved by protein precipitation of endosperm extracts with

sodium chloride at pH 2.1. Thus, the unique composition of endosperm extract

and molecular properties of collagen (high molecular weight and stability at

low pH) allowed the development of this extremely attractive and inexpensive

purification scheme.

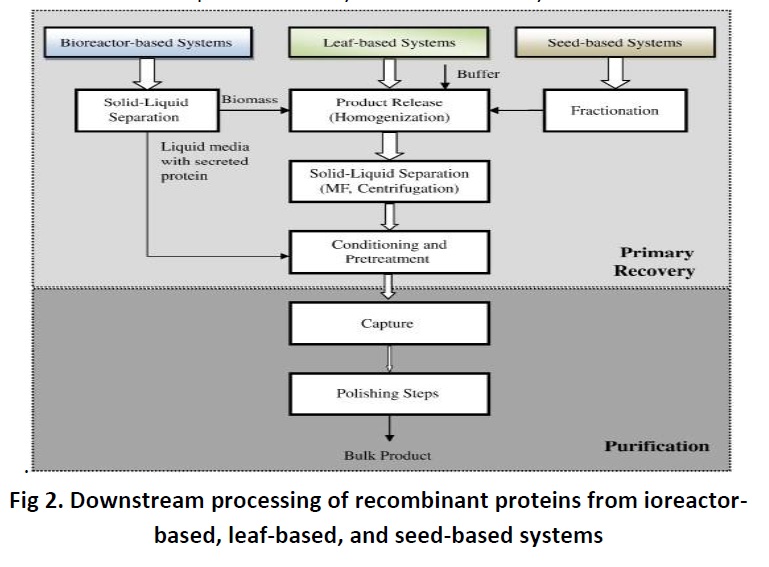

Although

much progress has been made over the past seven years, downstream processing

still requires further attention and technological breakthroughs to fulfil the

long anticipated goal of low manufacturing cost for plant-derived recombinant proteins.

However, improvements in downstream processing alone will not suffice; high

protein expression levels and assured product fidelity are also necessary.

Related Topics