Chapter: Mechanical : Strength of Materials : Stress, Strain and Deformation of Solids

Types of Stresses

TYPES OF STRESSES :

Only two basic stresses exists : (1) normal stress

and (2) shear shear stress. Other stresses either are similar to these basic

stresses or are a combination of these e.g. bending stress is a combination

tensile, compressive and shear stresses. Torsional stress, as encountered in

twisting of a shaft is a shearing stress.

Let

us define the normal stresses and shear stresses in the following sections.

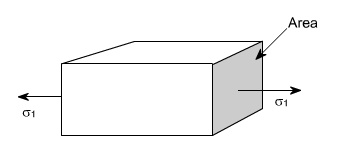

Normal stresses : We

have defined stress as force per unit area. If the stresses are normal to

the areas concerned, then these are termed as normal stresses. The normal

stresses are generally denoted by a Greek letter ( s )

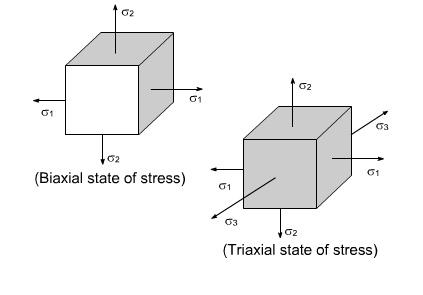

This is also known as uniaxial state of stress,

because the stresses acts only in one direction however, such a state rarely

exists, therefore we have biaxial and triaxial state of stresses where either

the two mutually perpendicular normal stresses acts or three mutually

perpendicular normal stresses acts as shown in the figures below :

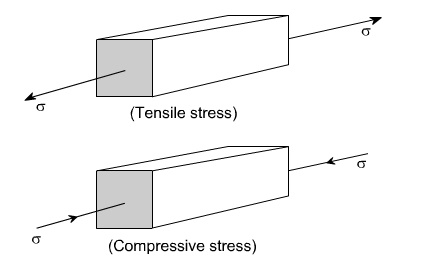

Tensile

or compressive stresses :

The normal stresses can be either tensile or

compressive whether the stresses acts out of the area or into the area

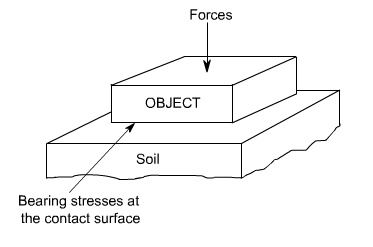

Bearing Stress : When

one object presses against another, it is referred to a bearing stress (

They are in fact the compressive stresses ).

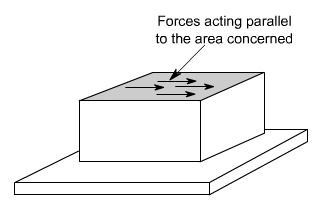

Shear

stresses :

Let us consider now the situation, where the cross

–sectional area of a block of material is subject to a distribution of forces

which are parallel, rather than normal, to the area concerned. Such forces are

associated with a shearing of the material, and are referred to as shear

forces. The resulting force interistes are known as shear stresses.

The resulting force intensities are known as shear

stresses, the mean shear stress being equal to

Where

P is the total force and A the area over which it acts.

Stress

is defined as the force per unit area. Thus, the formula for calculating stress

is:

s=

F/A

Where s denotes stress, F is load and A is the cross

sectional area. The most commonly used units for stress are the SI units, or

Pascals (or N/m2), although other units like psi (pounds per square

inch) are sometimes used.

Forces

may be applied in different directions such as:

•

Tensile or stretching

•

Compressive or squashing/crushing

•

Shear or tearing/cutting

•

Torsional or twisting

This gives rise to numerous corresponding types of

stresses and hence measure/quoted strengths. While data sheets often quote

values for strength (e.g compressive strength), these values are purely

uniaxial, and it should be noted that in real life several different stresses

may be acting.

Tensile

Strength

The tensile strength is defined as the maximum

tensile load a body can withstand before failure divided by its cross sectional

area. This property is also sometimes referred to Ultimate Tensile Stress or

UTS.

Typically, ceramics perform poorly in tension, while

metals are quite good. Fibres such as glass, Kevlar and carbon fibre are often

added polymeric materials in the direction of the tensile force to reinforce or

improve their tensile strength.

Compressive

Strength

Compressive strength is defined as the maximum

compressive load a body can bear prior to failure, divided by its cross

sectional area.

Ceramics typically have good tensile strengths and

are used under compression e.g. concrete.

Shear

Strength

Shear strength is the maximum shear load a body can

withstand before failure occurs divided by its cross sectional area.

This property is relevant to adhesives and fasteners

as well as in operations like the guillotining of sheet metals.

Torsional

Strength

Torsional

strength is the maximum amount of torsional stress a body can withstand before

it fails, divided by its cross sectional area.

This

property is relevant for components such as shafts.

Yield

Strength

Yield

strength is defined as the stress at which a material changes from elastic

deformation to plastic deformation. Once the this point, known as the yield

point is exceeded, the materials will no longer return to its original

dimensions after the removal of the stress.

Stress

is defined as the force per unit area. Thus, the formula for calculating stress

is:

Where s denotes stress, F is load and A is the cross

sectional area. The most commonly used units for stress are the SI units, or

Pascals (or N/m2), although other units like psi (pounds per square

inch) are sometimes used.

Forces

may be applied in different directions such as:

•

Tensile or stretching

•

Compressive or squashing/crushing

•

Shear or tearing/cutting

•

Torsion or twisting

This gives rise to numerous corresponding types of

stresses and hence measure/quoted strengths. While data sheets often quote

values for strength (e.g compressive strength), these values are purely uni

axial, and it should be noted that in real life several different stresses may

be acting

Deformation

of simple bars under axial load Deformation of bodies

Concept of strain : if

a bar is subjected to a direct load, and hence a stress the bar will change

in length. If the bar has an original length L and changes by an amount dL, the

strain produce is defined as follows:

Strain is thus, a measure of the deformation of the

material and is a non dimensional Quantity i.e. it has no units. It is simply a

ratio of two quantities with the same unit.

Shear strain: As

we know that the shear stresses acts along the surface. The action of the stresses

is to produce or being about the deformation in the body consider the

distortion produced b shear sheer stress on an element or rectangular block

This shear strain or slide is f and can be defined as the change in right

angle. or The angle of deformation g is then termed as the shear strain. Shear

strain is measured in radians & hence is non –dimensional

i.e.

it has no unit .So we have two types of strain i.e. normal stress & shear

stresses.

Hook's

Law :

A material is said to be elastic if it returns to

its original, unloaded dimensions when load is removed.

Hook's

law therefore states that Stress ( s ) a strain( Î )

Modulus of elasticity : Within

the elastic limits of materials i.e. within the limits in which Hook's

law applies, it has been shown that

Stress

/ strain = constant

This constant is given by the symbol E and is termed

as the modulus of elasticity or Young's modulus of elasticity Thus ,The value

of Young's modulus E is generally assumed to be the same in tension or

compression and for most engineering material has high, numerical value of the

order of 200 GPa

Poisson's ratio: If

a bar is subjected to a longitudinal stress there will be a strain in this direction

equal to s / E . There will also be a strain in all directions at right angles

to s . The final shape being shown by the dotted lines.

It has been observed that for an elastic materials,

the lateral strain is proportional to the longitudinal strain. The ratio of the

lateral strain to longitudinal strain is known as the poison's ratio .

Poison's

ratio ( m ) = - lateral strain / longitudinal strain

For

most engineering materials the value of m his between 0.25 and 0.33.

Deformation

of compound bars under axial load

For a prismatic bar loaded in tension by an axial

force P, the elongation of the bar can be determined as Suppose the bar is

loaded at one or more intermediate positions, then equation

(1) can be readily adapted to handle this situation,

i.e. we can determine the axial force in each part of the bar i.e. parts AB,

BC, CD, and calculate the elongation or shortening of each part separately,

finally, these changes in lengths can be added algebraically to obtain the

total charge in length of the entire bar.

When either the axial force or the cross –sectional

area varies continuosly along the axis of the bar, then equation (1) is no

longer suitable. Instead, the elongation can be found by considering a

deferential element of a bar and then the equation (1) becomes i.e. the axial

force Pxand area of the cross –section Ax must be expressed as functions of x.

If the expressions for Pxand Ax are not too complicated, the integral can be

evaluated analytically,

otherwise

Numerical methods or techniques can be used to evaluate these integrals.

Related Topics