Chapter: Mechanical : Strength of Materials : Stress, Strain and Deformation of Solids

True stress and true strain

True stress and true strain

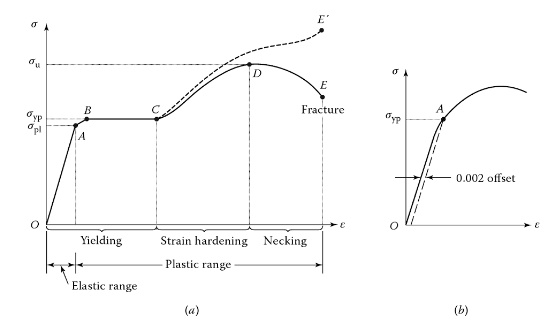

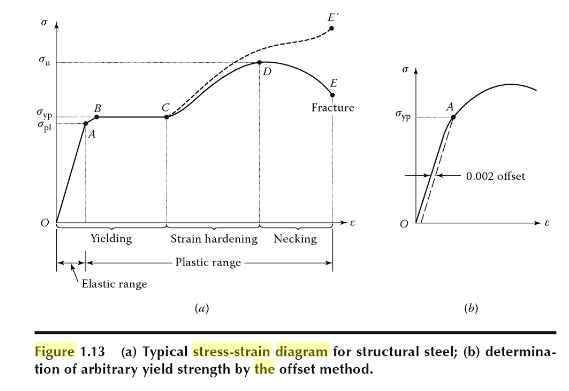

In drawing the stress-strain diagram as shown in

figure 1.13, the stress was calculated by dividing the load P by the initial

cross section of the specimen. But it is clear that as the specimen elongates

its diameter decreases and the decrease in cross section is apparent during

necking phase. Hence, the actual stress which is obtained by dividing the load

by the actual cross sectional area in the deformed specimen is different from

that of the engineering stress that is obtained using undeformed cross

sectional area as in equation 1.1 Though the difference between the true stress

and the engineering stress is negligible for smaller loads, the former is

always higher than the latter for larger loads.

Similarly, if the initial length of the specimen is

used to calculate the strain, it is called engineering strain as obtained in

equation 1.9

But some engineering applications like metal forming

process involve large deformations and they require actual or true strains that

are obtained using the successive recorded lengths to calculate the strain.

True strain is also called as actual strain or natural strain and it plays an

important role in theories of viscosity.

TYPES OF STRESSES :

Only two basic stresses exists : (1) normal stress

and (2) shear shear stress. Other stresses either are similar to these basic

stresses or are a combination of these e.g. bending stress is a combination

tensile, compressive and shear stresses. Torsional stress, as encountered in

twisting of a shaft is a shearing stress.

Related Topics