Chapter: Civil : Railway Airport Harbour Engineering : Railway Engineering : Railway Stations and Yards

Types of Railway Yards

Types of Yards

A yard is a system of tracks laid

out to deal with the passenger as well as goods traffic being handled by the

railways. This includes receipt and dispatch of trains apart from stabling,

sorting, marshalling, and other such functions. Yards are normally classified

into the following categories.

Coaching yard

The main function of a coaching

yard is to deal with the reception and dispatch of passenger trains. Depending

upon the volume of traffic, this yard provides facilities such as watering and

fuelling of engines, washing of rakes, examination of coaches, charging of

batteries, and trans-shipment of passengers.

Goods yard

A goods yard provides facilities

for the reception, stabling, loading, unloading, and dispatch of goods wagons.

Most goods yards deal with a full train load of wagons. No sorting,

marshalling, and reforming is done at goods yards except in the case of 'sick'

wagons or a few wagons booked for that particular station. Separate goods

sidings are provided with the platforms for the loading and unloading of the

goods being handled at that station.

Marshalling yard

A goods yard which deals with the

sorting of goods wagons to form new goods trains is called a marshalling yard.

This is discussed in detail in Section 26.8.1.

Locomotive yard

This is the yard which houses the

locomotive. Facilities for watering, fuelling, examining locomotives,

repairing, etc., are provided in this yard. The yard layout is designed

depending upon the number of locomotives required to be housed in the

locomotive shed. The facilities are so arranged that a requisite number of

locomotives are serviced simultaneously and are readily available for hauling

the trains. Such yards should have adequate space for storing fuel. The water

supply should be adequate for washing the locomotives and servicing them.

Sick line yard

Whenever a wagon or coach becomes

defective, it is marked 'sick' and taken to sick lines. This yard deals with

such sick wagons. Adequate facilities are provided for the repair of coaches

and wagons, which include examination pits, crane arrangements, train

examiner's office and workshop, etc. A good stock of spare parts should also be

available with the TXR (train examiner) for repairing defective rolling stock.

1

Marshalling Yard

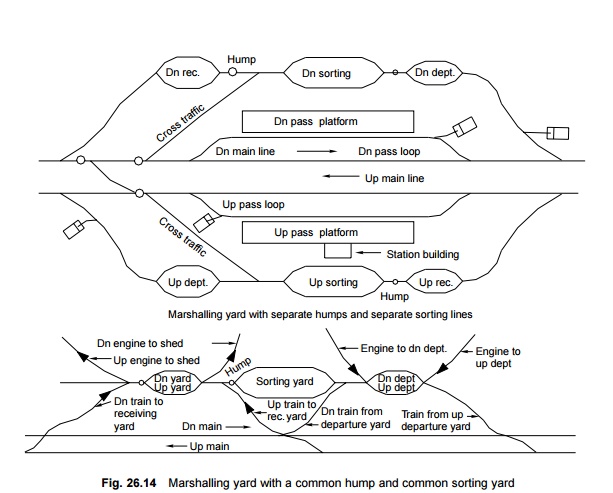

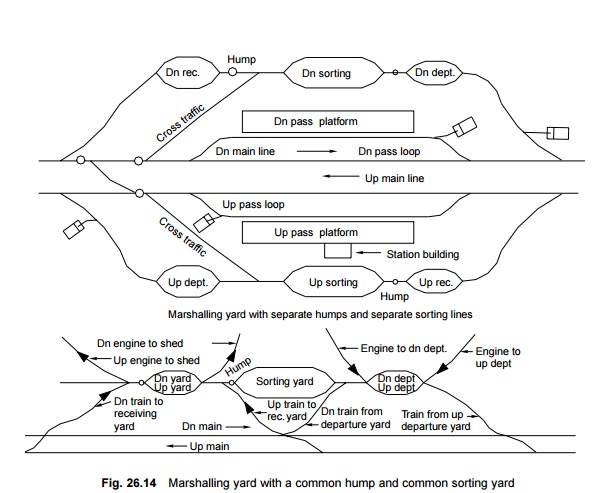

The

marshalling yard (Fig. 26.14) is a yard where goods trains are received and

sorted out, and new trains are formed and finally dispatched to various

destinations.

This yard receives loaded as well

as empty goods wagons from different stations for further booking to different

destinations. These wagons are separated, sorted out, properly marshalled, and

finally dispatched bearing full trainloads to various destinations. The

marshalling of trains is so done that the wagons can be conveniently detached

without much shunting en route at wayside stations.

Functions

A marshalling yard serves the

following functions at the specified locations within the yard itself.

Reception of trains Trains

are received in the reception yards with the help of various lines.

Sorting of trains Trains

are normally sorted with the help of a hump with a shunting neck and

sorting sidings.

Departure of trains Trains

depart from departure yards where various lines are provided for this

very purpose. Separate yards may be provided to deal with up and down traffic

as well as through trains, which need not be sorted out.

Principles of design

A marshalling yard should be so

designed that there is minimum detention of wagons in the yard and as such

sorting can be done as quickly as possible. These yards should be provided with

the necessary facilities such as a long shunting neck, properly designed hump,

braking arrangement in the shape of mechanical retarders, etc., depending upon

the volume of traffic. The following points should be kept in mind when

designing a marshalling yard.

(a) Through

traffic should be received and dispatched as expeditiously as possible. Any

idle time should be avoided.

(b) There

should be a unidirectional movement of the wagons as far as possible.

(c) There

should be no conflicting movement of wagons and engines in the various parts of

the yard.

(d) The leads

that permit the movement of wagons and train engines should be kept as short as

possible.

(e) The

marshalling yard should be well lighted.

(f) There

should be adequate scope for the further expansion of the marshalling yard.

Types

Marshalling yards can be

classified into three main categories, namely, flat yards, gravitation yards,

and hump yards. This classification is based on the method of shunting used in

the marshalling yard.

Flat yard In this

type of yard, all the tracks are laid almost level and the wagons are

relocated for sorting, etc., with the help of an engine. This method is costly,

as it involves frequent shunting, which requires the constant use of locomotive

power. The time required is also more as the engine has to traverse the same

distance twice, first to carry the wagons to the place where they are to be

sorted and then to return idle to the yard. This arrangement, therefore, is

adopted when

(a) there is

limitation of space,

(b) there is

a severe limitation of funds, or

(c) the number

of wagons dealt with by the marshalling yard is very low.

Gravitation yard In this

yard, the level of the natural ground is such that it is possible to lay

some tracks at a gradient. The tracks are so laid that the wagons move to the

siding assigned for the purpose of sorting by the action of gravity. Sometimes,

shunting is done with the help of gravity assisted by engine power. However, it

is very seldom that natural ground levels are so well suited for gravitation

yards.

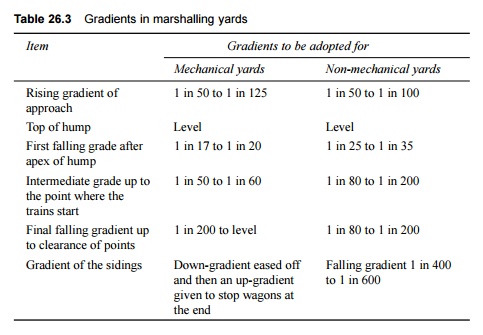

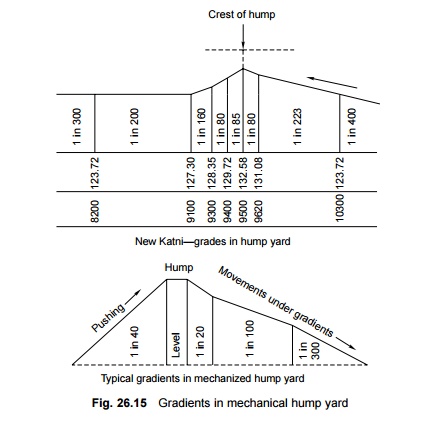

Hump yard In this

yard, an artificial hump is created by means of proper earthwork. The

wagons are pushed up to the summit of the hump with the help of an engine from

where they slide down and reach the sidings under the effect of gravity. A hump

yard, therefore, can be said to be a gravitation yard as shunting is done under

the effect of gravity. The gradients normally adopted in this regard are listed

in Table 26.3. These are, however, only recommended gradients and the final

gradient for a particular yard is decided after a test run of the trains over

the humps, taking into consideration the rolling quality of different types of

wagons and the spacing between successive groups of wagons. The topography of

the location of the yard also plays an important role in deciding the gradient.

Table

26.3 Gradients in

marshalling yards

Regulation

of speeds in hump yards The speed of the wagons is regulated to ensure

that they are kept in a stable condition in the siding where they are to be

sorted, so that there is least damage to them. The regulation of speed is done

as follows.

Mechanical

method In this method, wagons are slowed down

automatically with the help of 'retarders' (Fig. 26.15).

Retarders' normally in the shape of bars fixed on either side of the track, operate

electrically or electromechanically and offer resistance to the movement of

wagons by pressing against the sides of the moving wheels. This finally stops

the wagons at the appropriate place. Such mechanical retarders are used

extensively in Germany and on other developed railways.

Non-mechanical yard In a

non-mechanical yard, the speed of the wagon is regulated manually

with the help of hand brakes or skids. A shunting porter runs alongside the

wagons and applies a hand brake to the wagon at an appropriate place, making

the wagon slip and stop. Skids are also used to slow down the wagons. Skids are

placed on the track; they get dragged by the rolling wagon and the friction

thus developed reduces the speed of the wagon and stops it at the desired

location.

Design of various constituents

The design details of the various

components of a marshalling yard are discussed below.

Spacing

of marshalling yards This depends upon the average distance that a long-distance

train can go. If the lead is 500 km and the section train can go up to 100 km,

the approved spacing of a marshalling yard is 400 km.

Siting of marshalling yard A

marshalling yard is normally sited at a junction point, a depot yard to

a group of collieries, a feeder yard for a big terminal point, or a steel

plant, etc.

Reception yard The

number of lines to be included in a reception yard depends upon the

number of trains to be received and on the frequency of their arrival. Normally

one reception line is provided for every three to four trains. The approved

length of a siding is normally 700 m for BG and 650 m for MG.

Shunting neck The

length of the shunting neck should be longer than the longest train.

Hump The hump

should be designed to meet the following objectives.

(a) It should

be such that even the wagon whose movements are affected the worst by the most

adverse weather conditions can clear the fouling mark, when sent to the

outermost siding.

(b) It should

be such that a successive group of wagons are separated from each other to the

extent that it enables the point between them to be operated upon so that the

wagons can be sent to various sidings.

(c) The hump

should be such that the speed of the wagons is so regulated that there is no

damage to the wagons when they bump against each other in the sorting lines.

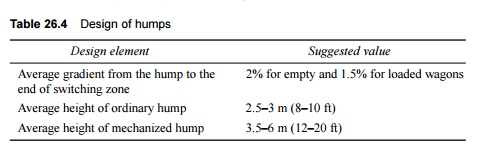

The figures given in Table 26.4 can be taken as a rough guide for choosing the

design of the humps.

Table

26.4 Design of humps

Sorting yard The

number of lines to be included in the sorting yard depends upon the

number of destinations for which the trains are to be assembled. The length of

each sorting line is about 15 to 20% more than that of a normal train so that

there is provision of some space behind the wagons. The layout of the sorting

yard may be of the ladder or the balloon type. The speed of the wagons is

controlled by hand brakes while the skids and the mechanical retarders are

controlled by manual and mechanical means, respectively.

Departure

yard The number of lines to be included in a departure yard depends

upon the number of trains proposed to be dispatched from the yard and on

the frequency of their departure. Some engineers feel that there is no need for

a separate dispatching yard because it unnecessarily increases the length of the

marshalling yard. According to them, trains should be dispatched straight from

the sorting lines. This arrangement, however, runs into problems if the

departure of the trains is delayed on account of operational reasons.

The pattern of transportation of

goods traffic has changed drastically in the recent past. Now, most goods

traffic is carried as trainloads from point to point. The loading of piecemeal

wagons has also been drastically reduced. Consequently, the need and importance

of goods marshalling yards has reduced considerably.

Related Topics