Chapter: Mechanical : Fluid Mechanics And Machinery : Turbines

Turbines - Fluid Mechanics

TURBINES

PRE REQUEST DISCUSSION

Hydraulic Machines

are defined as

those machines which

convert either hydraulic energy (energy possessed

by water) into mechanical energy (which is further

converted into electrical energy) or

mechanical energy into hydraulic

energy.

The hydraulic machines, which convert the

hydraulic energy into mechanical energy, are called turbines.

Turbines are defined as the hydraulic machines

which convert hydraulic energy into mechanical energy. This mechanical energy

is used in running an electric generator which is directly coupled to the shaft

of the turbine. Thus the mechanical energy is converted into electrical energy.

The electric power which is obtained from the hydraulic energy (energy of water)

is known as Hydro- electro power.

In our subject point of view, the following

turbines are important and will be discussed one by one.

1. Pelton

wheel

2. Francis

turbine

3. Kaplan

turbine

Concept

Turbines are defined as the

hydraulic machines which convert hydraulic energy into mechanical energy. This

mechanical energy is used in running an electric generator which is directly

coupled to the shaft of the turbine

FLUID TYPES OF

TURBINE

Water Hydraulic

Turbine

Steam Steam

Turbine

Froen Vapour

Turbine

Gas

or air Gas Turbine

Wind Wind

Mills

CLASSIFICATION OF HYDRAULIC TURBINES

1. According

to the action of the water flowing

2. According

to the main direction of flow of water

3. According

to the head and quality of water required

4. According

to the specific speed

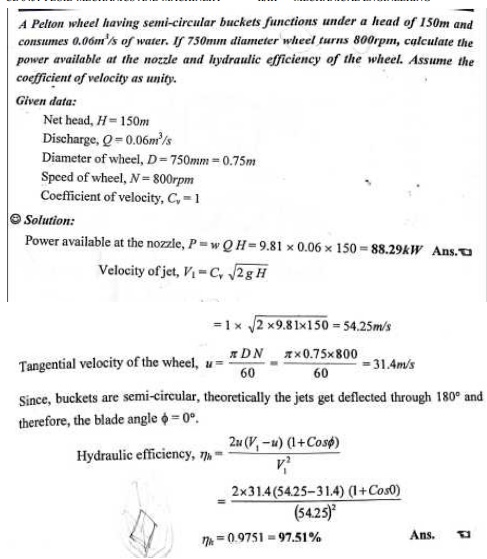

HEAD AND EFFICIANCES OF PELTON WHEEL

1. Gross

head

2. Effective

or Net head

3. Water and

Bucket power

4. Hydraulic

efficiency

5. Mechanical

efficiency

6. Volume

efficiency

7. Overall

efficiency

IMPULSE TURBINE

In an impulse turbine, all the

energy available by water is converted into kinetic energy by passing a nozzle.

The high velocity jet coming out of the nozzle then impinges on a series of

buckets fixed around the rim of a wheel.

Tangential Flow Turbine, Radial And Axial Turbines

1. Tangential flow turbine

In a tangential flow turbine,

water flows along the tangent to the path of runner. E.g. Pelton wheel

2. Radial flow turbine

In a radial flow turbine, water

flows along the radial direction and mainly in the plane normal to the axis of

rotation, as it passes through the runner. It may be either inward radial flow

type or outward radial flow type.

3. Axial flow turbine

In axial flow turbines, water

flows parallel to the axis of the turbine shaft. E.g. kaplan turbine

4. Mixed flow turbine

In a mixed flow turbine, the

water enters the blades radiallsy and comes out axially and parallel to the

turbine shaft .E.g. Modern Francis turbine.

In our subject point of view, the

following turbines are important and will be discussed one by one

1. Pelton

wheel

2. Francis

turbine

3. Kaplan

turbine

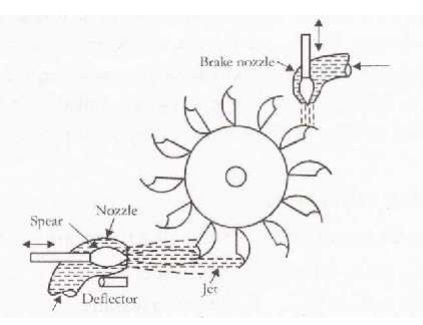

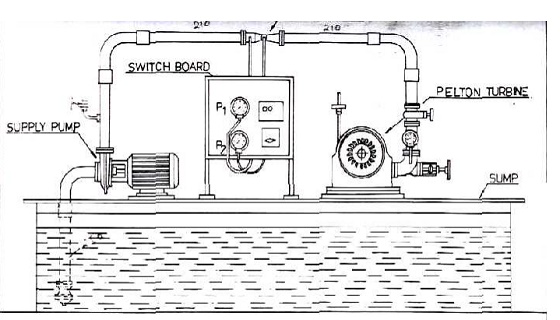

PELTON WHEEL OR PELTON TURBINE

The Pelton wheel is a tangential

flow impulse turbine and now in common use. Leston A Pelton, an American

engineer during 1880,develops this turbines. A pelton wheel consists of

following main parts.

1. Penstock

2. Spear and

nozzle

3. Runner

with buckets

4. Brake

nozzle

5. Outer

casing

6. Governing

mechanism

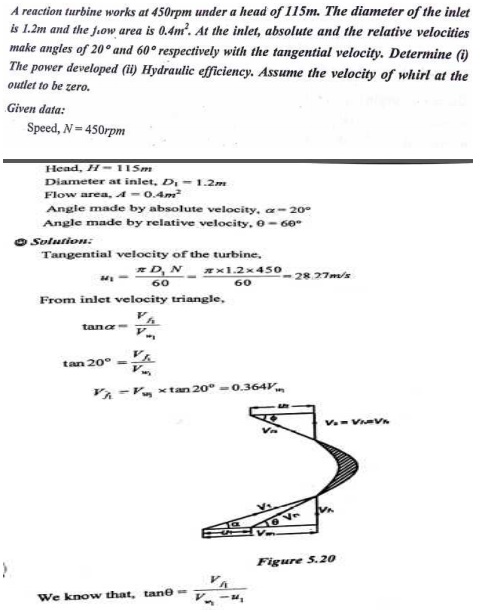

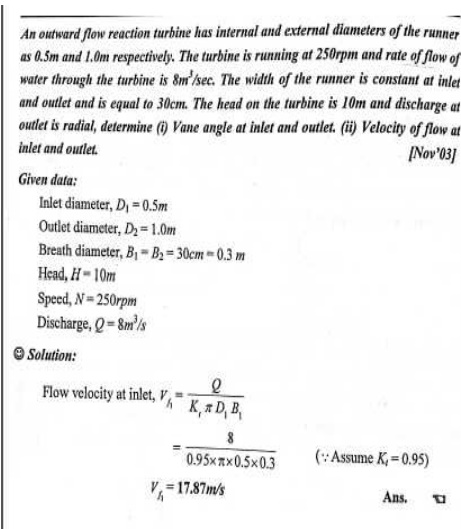

1 VELOCITY TRIANGLES, WORKDONE, EFFICIENCY OF

PELTON

WHEEL INLET AND OUTLET VECTOR DIAGRAMS

Let V =

Velocity of the jet

u =

Velocity of the vane (cups) at the impact point u

= DN/ 60

where D = Diameter of the wheel

corresponding to the impact point = Pitch circle diameter.

At inlet the shape of the vane is

such that the direction of motion of the jet and the vane is the same.

i.e., Ȑ= 0, ș= 0

Relative velocity at inlet

Vr = V —u

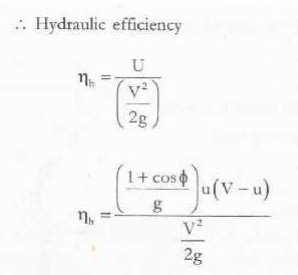

Hydraulic efficiency

This is the ratio of the workk

done per second per head at inlet to the turbine.

Energy head at inlet = V2/2g

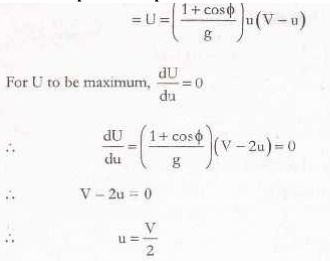

Condition

for maximum hydraulic efficiency

For a given jet velocity for efficiency to be

maximum, word done should be maximum

Work done per second per N of

water

Hence for the condition of

maximum hydraulic efficiency, the peripheral speed of the turbine should reach

one half the jet speed.

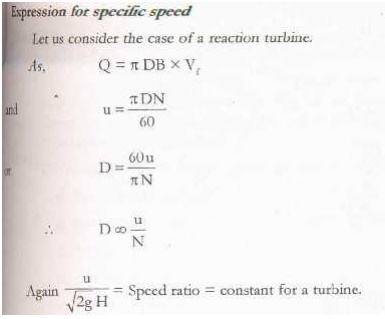

SPECIFIC

SPEED

[ The speed of any water turbine is represented by

N rpm. A turbine has speed, known as specific speed and is represented by N

‘ Specific

speed of a water turbine in the speed at which a geometrically similar

turbine

would run if producing unit power (1 kW) and working under a net head of 1 m.

Such a turbine would be an imaginary one and is called specific turbine.

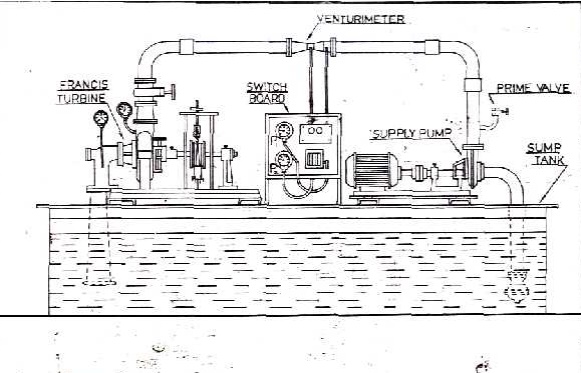

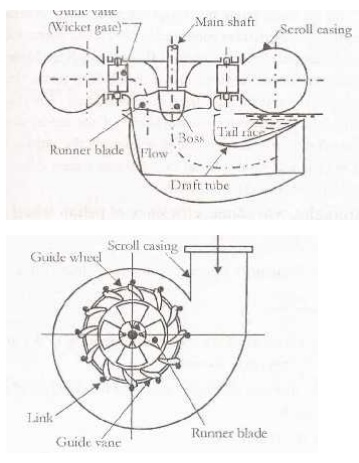

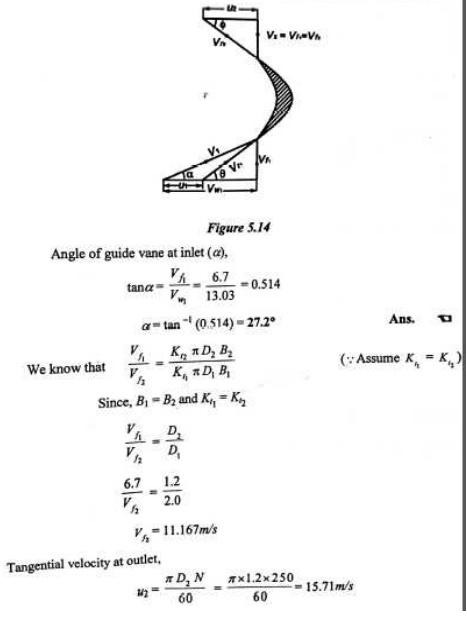

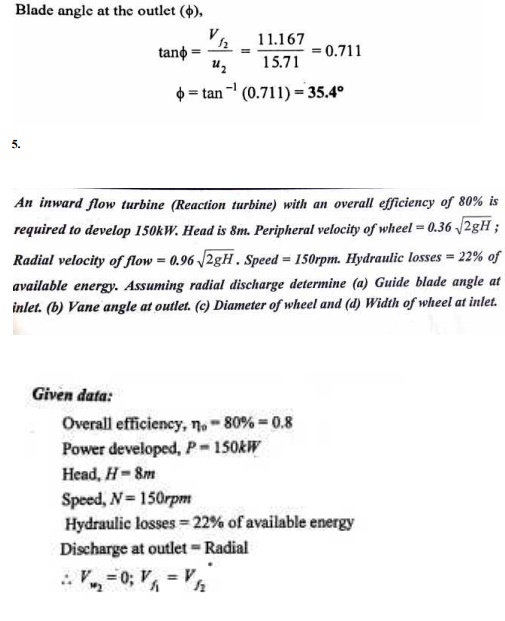

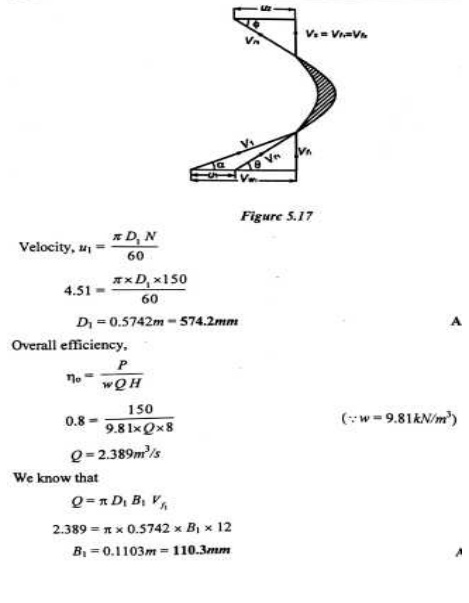

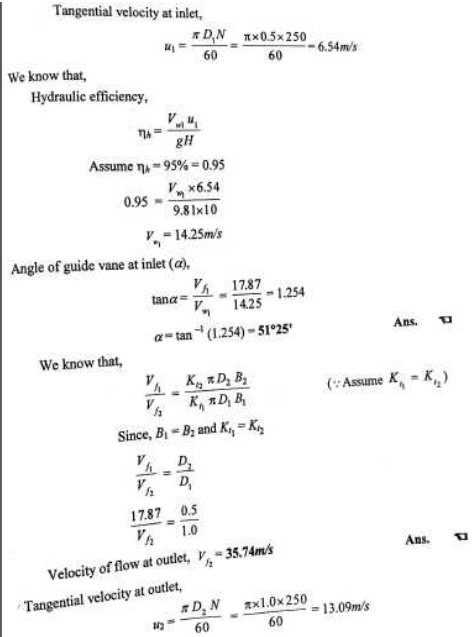

FRANCIS TURBINE

Francis turbine is an i nward

flow reaction turbine. It is developed b y the American engineer James B.

Francis. In the earlier stages, Francis turbine had a purely ra dial floe

runner. But the modern Francis turbine is a mixed flow reaction turbine in

which the water enters the runner radially at its outer peripher y and leaves

axially at its centre. This arrangement provides larger discharge area with

prescribed diameter of the runner. The main parts such as

1. Penstock

2. Scroll or

Spiral Casing

3. Speed

ring or Stay ring

4. Guide

vanes or Wickets gat es

5. Runner

and runner blades

6. Draft

tube

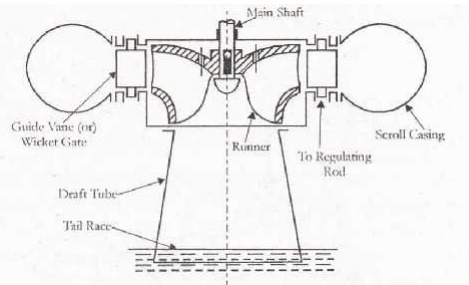

KAPLAN TURBINE

A Kaplan turbine is an axial flow

reaction turbine which was developed by Austrian engineer V. Kaplan. It is

suitable for relatively low heads. Hence, it requires a large quantity of water

to develop large power. The main parts of Kaplan turbine, they are

1. Scroll

casing

2. Stay ring

3. Guide

vanes

4. Runner

5. Draft

tube

PERFORMANCE OF TURBINES

Turbines are often required to work under varying conditions

of head, speed, output and gate opening. In order to predict their behavior, it

is essential to study the performance of the turbines under the varying

conditions. The concept of unit quantities and specific quantities are required

to

The behavior of a

turbine is predicted working under different conditions.

Comparison is

made between the performance of turbine of same type but of different sizes.

The performance of turbine is compared with different types.

DRAFT TUBE

The pressure at the exit of the runner of a

reaction turbine is generally less than atmospheric pressure. Thus the water at

the exit of the runner cannot be directly discharged to the tail race. A pipe o

gradually increasing area is used for discharging water form the exit of the

turbine to the tail race. This pipe of gradually increasing area is called a

draft tube.

SPECIFIC

SPEED

Homologus units are required in governing

dimensionless groups to use scaled models in designing turbomachines, based geometric

similitude.

Specific speed is the speed of a geometrically

similar turbine, which will develop unit power when working under a unit head.

The specific speed is used in comparing the different types of turbines as

every type of turbine has different specific speed. In S.I. units, unit power

is taken as one Kw and unit as one meter.

GOVERNING OF TURBINES

All the modern hydraulic turbines are directly

coupled to the electric generators. The generators are always required to run

at constant speed irrespective of the variations in the load. It is usually

done by regulating the quantity of water flowing through the runner in

accordance with the variations in the load. Such an operation of regulation of

speed of turbine runner is known as governing of turbine and is usually done

automatically by means of a governor.

Applications

1. To produce the power by water.

GLOSSARY

HP –Horse power

KW- Kilo watts

Related Topics