Chapter: Mechanical and Electrical : Power Plant Engineering : Power From Renewable Energy

Thermo Electric conversion system

Thermo Electric conversion system

Thermo electric Conversion System:

The quest for a reliable, silent, energy converted with no

moving parts that transforms heat to electrical power has led engineers to

reconsider a set of phenomena called the Thermoelectric effects. These effects,

known for over a hundred years, have permitted the development of small, self

contained electrical power sources.

Seebeck (thermoelectric) effect:

The

German Scientist Seebeck (in 1822) discovered that if two dissimilar material

are joined to form a loop and the two junctions maintained at different

temperatures, and e.m.f will be set up around the loop. The magnitude of e.m.f.

will be E = aDT where DT is the temperature difference

between the two junctions and ais the Seebeck co-efficient. This

effect has long been used in thermocouples to measure temperatures.

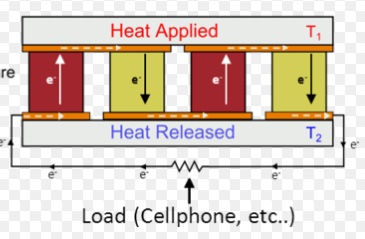

Thermoelectric Power Generator:

Figure

shows a schematic diagram of a thermoelectric power generator. The thermocouple

materials A and B are joined at the hot end, but the other ends are kept cold;

an electric voltage or electromotive force is then generated between the cold

ends. A.D.C (Direct Current) will flow in a circuit or load connected between

these ends. The flow of current will continue as long as the heat

is

supplied to the hot junction and removed from the cold ends. For a given

thermocouple, the voltage and electric power output are increased by increasing

the temperature difference between the hot and cold ends.

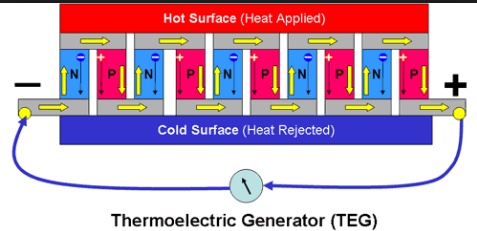

In

a practical thermoelectric converter, several thermocouples are convected in

series to increases both voltage and power as shown in figure. If the output

voltage is insufficient to operate a particular device or equipment, it can be

increased, with little loss of power, by an inverted transformers combination.

The direct current generated by the thermocouples is first changed into

alternating current of essentially the same average by means of an inverter. The

alternating current and voltage in then increased to the desired value with the

help of a transformer. The high voltage alternating current can be reconverted

into direct current if required, by the use of a rectifier.

The source of heat for a thermoelectric generator may be

small oil or gas burner, a radio- isotope or direct solar radiation.

Figure: Thermoelectric generator.

Figure:

Thermocouples in series (to increase voltage).

A

typical couple operating with hot and cold junction temperatures of 600°C and 200°C could

be designed to give about 0.1 V and 2 A i.e., about 0.5 W, so that a 1 kW

device could require about 5000 couples in series.

Taking

into account mechanical characteristics, stability under operating conditions

and ease of fabrication, Bismuth telluride appears to be most suitable

material. It can be alloyed with such materials as Bismuth selenide, Antimony

telluride, Lead selenide and Tin telluride to give improved properties.

Research

is being carried out on the possibility of using thermoelectric devices within

the core of a nuclear reactor. The hot junction would be located on the fuel

element and the cold junctions in contact with the coolants.

Related Topics