Chapter: Mechanical : Manufacturing Technology : Turning Machines

Taper turning and Thread cutting methods

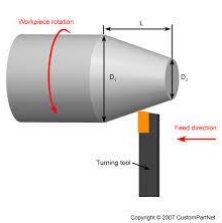

Taper turning methods

A taper is a conical shape. Tapers can be cut with lathes quite easily. There are some common methods for turning tapers on an center lathe,

Using a form tool: This type of tool is specifically designed for one cut, at a certain taper angle. The tool is plunged at one location, and never moved along the lathe slides. v Compound Slide

Method: The compound slide is set to travel at half of the taper angle. The tool is then fed across the work by hand, cutting the taper as it goes. v Off-Set Tail Stock: In this method the normal rotating part of the lathe still drives the workpiece (mounted between centres), but the centre at the tailstock is offset towards/away from the cutting tool. Then, as the cutting tool passes over, the part is cut in a conical shape. This method is limited to small tapers over long lengths.The tailstock offset h is defined by

h = Lsinα, where L is the length of work piece, and α is the half of the taper angle.

Thread cutting methods

Different possibilities are available to produce a thread on a lathe. Threads are cut using lathes by advancing the cutting tool at a feed exactly equal to the thread pitch. The single-point cutting tool cuts in a helical band, which is actually a thread. The procedure calls for correct settings of the machine, and also that the helix be restarted at the same location each time if multiple passes are required to cut the entire depth of thread. The tool point must be ground so that it has the same profile as the thread to be cut.

Another possibility is to cut threads by means of a thread die (external threads), or a tap (internal threads). These operations are generally performed manually for small thread diameters.

Related Topics