Chapter: Mechanical : Manufacturing Technology : Turning Machines

Center Lathes

Center Lathes

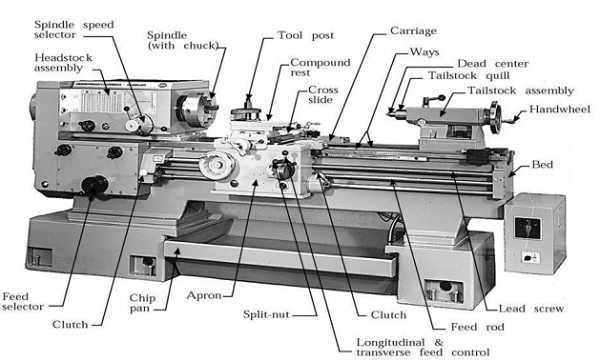

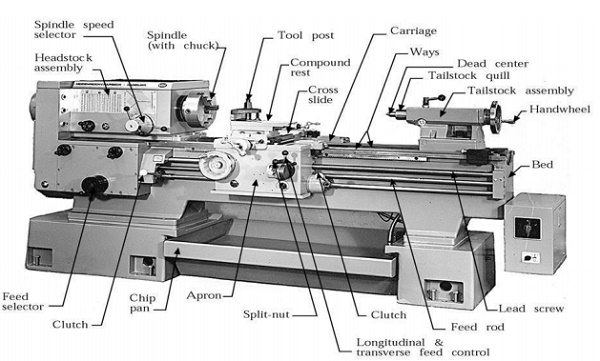

A lathe is a machine tool that rotates the work piece against a tool whose position it controls. The spindle is the part of the lathe that rotates. Various work holding attachments such as three jaw chucks, collets, and centers can be held in the spindle. The spindle is driven by an electric motor through a system of belt drives and gear trains. Spindle rotational speed is controlled by varying the geometry of the drive train.

The tailstock can be used to support the end of the workpiece with a center, or to hold tools for drilling, reaming, threading, or cutting tapers. It can be adjusted in position along the ways to accommodate different length workpieces. The tailstock barrel can be fed along the axis of rotation with the tailstock hand wheel.

The carriage controls and supports the cutting tool. It consists of:

A saddle that slides along the ways;

An apron that controls the feed mechanisms;

A cross slide that controls transverse motion of the tool (toward or away from the operator);

A tool compound that adjusts to permit angular tool movement; v a tool post that holds the cutting tools.

There are a number of different lathe designs, and some of the most popular are discussed here.

Centre lathe

The basic, simplest and most versatile lathe.

This machine tool is manually operated that is why it requires skilled operators. Suitable for low and medium production and for repair works.

There are two tool feed mechanism in the engine lathes. These cause the cutting tool to move when engaged.

The lead screw will cause the apron and cutting tool to advance quickly. This is used for cutting threads, and for moving the tool quickly.

The feed rod will move the apron and cutting tool slowly forward. This is largely used for most of the turning operations.

Work is held in the lathe with a number of methods.

Between two centers. The work piece is driven by a device called a dog; the method is suitable for parts with high length-to-diameter ratio.

A 3 jaw self-centering chuck is used for most operations on cylindrical work parts. For parts with high length-to-diameter ratio the part is supported by center on the other end.

Collet consists of tubular bushing with longitudinal slits. Collets are used to grasp and hold bar stock. A collet of exact diameter is required to match any bar stock diameter.

A face plate is a device used to grasp parts with irregular shapes:

Related Topics