Chapter: Mechanical : Mechatronics : Actuation System

System Models and Controllers Building

SYSTEM MODELS

AND CONTROLLERS BUILDING

BLOCKS OF

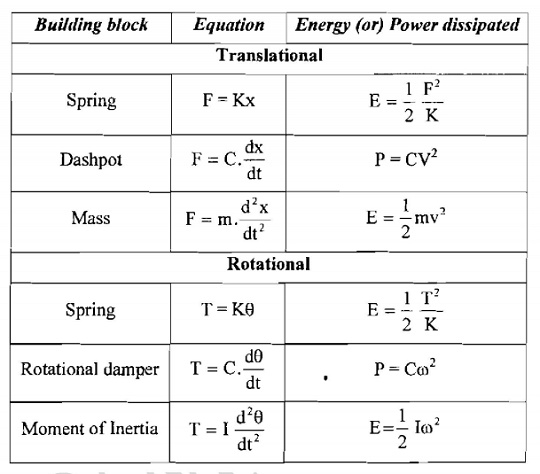

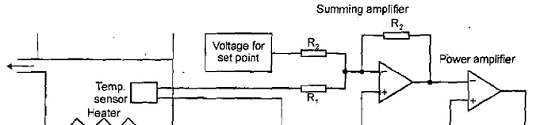

MECHANICAL SYSTEM:

BLOCKS OF MECHANICAL SYSTEM:BUILDING

BLOCKS OF ELECTRICAL SYSTEM:

TYPES OF CONTROL MODES:

The Two – Step Mode:

The two-step mode in which the controller is essentially just

a switch which is activated by the error signal and supplied just an on-off

correcting signal.

An example of the two-step mode of control is the

bimetallic thermoset at that might be used with a simple temperature control

system.

This is just a switch which is switched on or off

according to the temperature then the bimetallic ship is in an off position and

the heater is off.

If the room temperature falls below the required

temperature then the bimetallic strip moves into an on position and the heater

is switched fully on. The controller in this case

can be in

only two positions, on or off.

The

Proportional Mode (P):

The proportional mode (P) which products a control

action that is proportional to the error. The correcting signal thus becomes

bigger the bigger the error.

Thus as

the error is reduced the amount of correction is reduced and the correcting

process slows down.

The

proportional mode, the size of the controller output is proportional to the

size of the error.

K = 100 / Proportional

Band

Change

in Output (s) = Kp

* E(s)

Transformer

function = Change

in Output (s) / E(s)

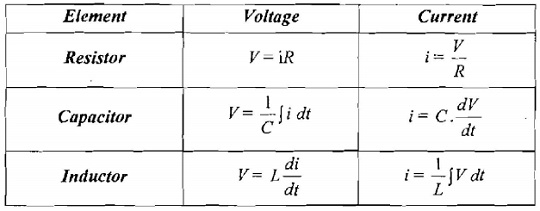

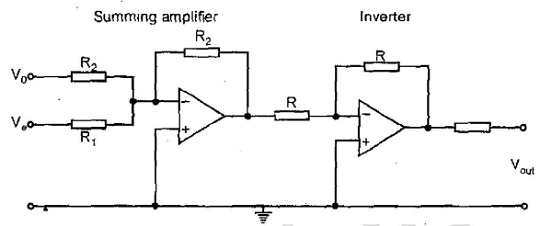

Electronic Proportional Controller:

Example for Proportional Controller:

The Derivative Mode (D):

The derivative mode (D) which products a control action that

is proportional to the rate at which are errors is changing.

When

there is a sudden change in the error signal the controller gives a large

correcting signal

When there is a gradual change only a small corrections signal

is produced. Derivative control can be considered to be a form of anticipatory

control in that the existing rate of

change of

error is measured, a coming larger error is anticipated and correction applied

before

the larger error has arrived.

Derivative mode of control the change in controller output

from the set point value is proportional to the rate of change with time of the

error signal

t – IO =

KD

Proportional Plus Derivative Mode:

Change in

output from the set point = KP e + KD

Iout

= KP e + KD + I0

The Integral Mode (I):

The integral mode (I) which produces a control action that is

proportional to the integral of the error with time.

Thus a constant error signal will produce an increasing

correcting signal. The correction continues to increase as long the error

persists.

The integral mode of control is one where the rate of change

of the control output I is proportional to the input error signal.

Proportional

Plus Integral Control:

Iout = KP e + KI ∫ +

IO

Transfer Function

= Kp + = (S + )

Combinations of Modes:

Proportional plus derivative modes (PD), proportional plus

integral modes (PI), proportional plus integral plus derivative modes (PID).

The term

three – term controller is used for PID control.

DIGITAL CONTROLLERS:

The tern digital control is used when the digital controller,

basically a microprocessor is in control of the closed-loop control system.

The

controller receives inputs from sensors, executes control programs and provides

the output to the correction elements.

The controllers require inputs which are digital, process the

information in digital form and give an output in digital form.

Since many control systems have analogue measurements an

analogue-to-digital converter (ADC) is used forth inputs.

A clock supplies a pulse at regular time intervals and

dictates when samples of the controlled variable are taken by the ADC.

The samples

are then converted

to digital signals

which are compared

by the

microprocessor

with the set point value to give the error signal.

The

microprocessor can then initiate a control mode to process the error signal and

give a digital output.

The control mode used by the microprocessor is determined by

the program of instruction used by the microprocessor for processing the

digital signals, i.e., the

software.

The digital output, generally after processing by a

digital-to-analogue converter since correcting elements generally require

analogue signals can be used to initiate the

correcting

action

A digital

controller basically operates the following cycle of events:

Samples

the measured value.

Compares

it with the set value and establishes the error.

Carries out calculations based on the error value and stored

values of previous inputs and outputs to obtain the output signal

Sends the

output signal to the DAC.

Waits

until the next sample time before repeating the cycle.

VELOCITY CONTROL:

Consider

the problem of controlling the movement of a load by means of a motor.

Time will

thus be taken for the system to respond to an input signal.

A higher speed of respond, with fewer oscillations, can be

obtained by using PD rather than just P control.

There is, however, alternative of achieving the same effect

and this is by the use of a second feedback loop which gives a measurement

related to the rate at which the

displacement

is changing.

This is

termed velocity feedback.

The velocity feedback might involve the use of a

Tachogenerator giving a signal proportional to the rotational speed of the

motor shaft and hence the rate at which the

displacement

is changing and the displacement might be monitored using a rotary

potentiometer

ADAPTIVE CONTROL:

An adaptive control system which 'adapts' to changes and

changes its parameters to fit the circumstances prevailing.

The

adaptive control system is based on the use of a microprocessor as the

controller.

Such a

device enables the control mode and the control parameters used to be adapted

to fit the circumstances, modifying them as the circumstances change.

Stages of Adaptive Control System:

An

adaptive control system can be considered to have three stages of operation.

Starts to

operate with controller conditions set on the basis of an assumed condition.

The

desired performance is continuously compared with the actual system

performance.

The control system mode and parameters are automatically and

continuously adjusted in order to minimise the difference between the desired

and actual system performance.

Forms of Adaptive Control System:

Adaptive control systems can take a number of forms. Three

commonly used forms are: Gain-scheduled control

Self –

tuning

Model-reference

adaptive systems

Gain – Scheduled Control:

With gain-scheduled control or, as it is sometimes referred

to, pre-programmed adaptive control, pre-set changes in the parameters of the

controller are made on the basis of some

auxiliary

measurement of some process variable.

The term

gain-scheduled control was used because the only parameter originally adjusted

was gain

Self – Tuning:

With self-tuning control the system continuously tunes its own

parameters based on monitoring the variable that the system is controlling and

the output from the controller.

Self-tuning is often found in commercial PID controller, it

generally then being referred to as auto-tuning.

When the operator presses a button, the controller injects a

small disturbance into the system and measures the response.

Response is compared to the desired response and the control

parameters adjusted, by modified Ziegler-Nichol rule, to bring the actual

response closer to the desired response.

Model-Reference Adaptive Systems:

The

model-reference system an accurate model of the system is developed.

The set value is then used as an input to both the actual and

the model systems and the difference between the actual output and the output

from the model compared. The difference in these signals is then used m adjusts

the parameter of the controller to minimise the difference.

Related Topics