Chapter: Mechanical : Manufacturing Technology : Sheet Metal Process

Stretch Forming Operations

Bending

The plastic deformation of metals about a linear axis with little or no change in the surface area. The purpose of bending is to form sheet metal along a straight line

STRETCH FORMING OPERATIONS

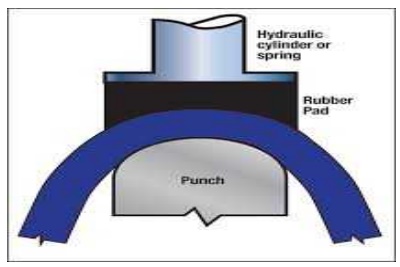

In this process, the sheet metal is clamped along the edges and then stretched over a die (OR) FORM BLOCK, which moves upward, downward (or) side ways, depending on the particular machine.

It is used to make aircraft wing-skin panels, automobile door panels and window frames. The desirable qualities in the metal for maximum strechability are as follows.

1.Fine grain structure. 2.toughness.

3.LARGE SPREAD between the tensile yield and ultimate strength.

Working.

It consists of placing the sheet –metal under a tensile load over a forming block and stretching it beyond its elastic limit and to te plastic range, thus cause a permanent set to take place.

Two Basic Forms of Stretch forming are,

1.Stretch forming, 2.Stretch – Wrap forming.

Advantages

1. In a single operation, blanks can be stretched.

2. Heat treatment before and after stretching process is not required.

3. Spring back effect is minimized.

4. Tooling cost is low.

5. Direct bending is not introduced, and plastic deformation is due to pure tension.

6. It is suitable for low volume production.

Disadvantages.

1.uneven thickness of blank cannot be stretched.

2.The maintanence cost of the hydraulic cylinders is high.

Related Topics