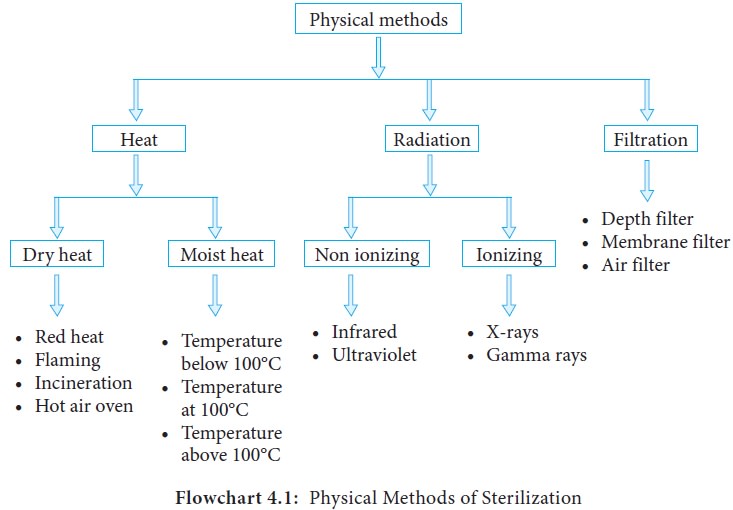

Chapter: 11th Microbiology : Chapter 4 : Sterilization

Sterilization by Filtration

Sterilization by Filtration

Filtration is an effective and reasonably economical method of

sterilization. It is used to sterilize heat-sensitive fluids, and air. It is

particularly useful for solutions containing toxins, enzymes, drug, serum and

sugars. Sugar solutions used for the cultivation of microorganisms tend to

caramelise during autoclaving and so they are best sterilized by filtration.

Filtration is also used extensively in beer and wine industries. Filters with

known pore sizes which are sufficiently small to hold back bacteria are

employed. Recently filters that can remove viruses are also available.

Filtration is an excellent way to remove the microbial

population from solution containing heat sensitive material.

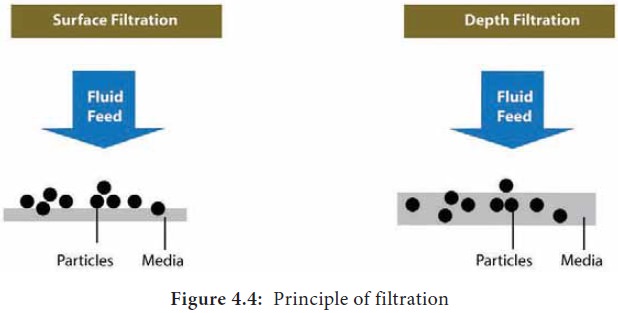

There are two types of filters namely (Figure 4.4):

1.

Membrane filter (surface filtration) and

2.

Depth filter

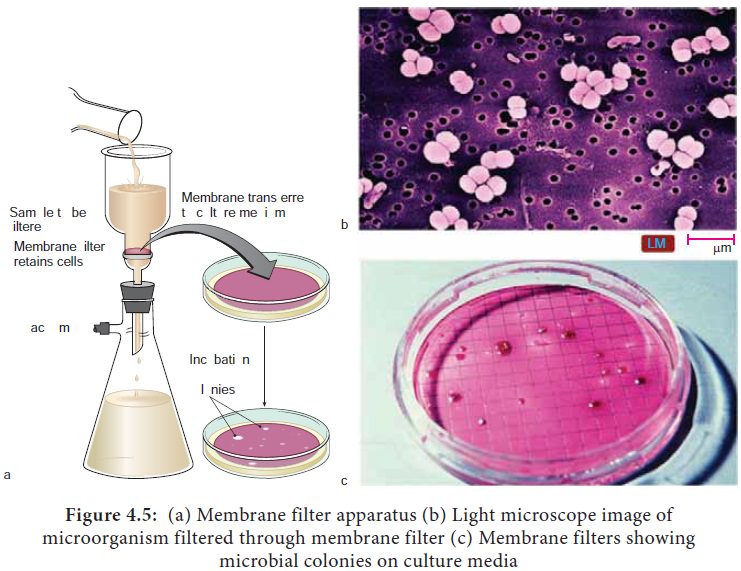

Membrane filters

Membrane filtration is used for preparing heat-labile culture

media components. It

Membrane filters are made up of either cellulose acetate,

cellulose nitrate, polycarbonate, polyvinylidene fluoride or other synthetic

porous materials. These filters remove microorganisms by screening them out,

such as a sieve separates large sand particles from small ones. Membranes with

pore size of 0.2μm in diameter are used to remove most vegetative cells but not

viruses. These filters are used to sterilize pharmaceutical products,

ophthalmic solutions, culture media, oils, antibiotics, and other heat

sensitive solutions (Figure 4.5a, b & c).

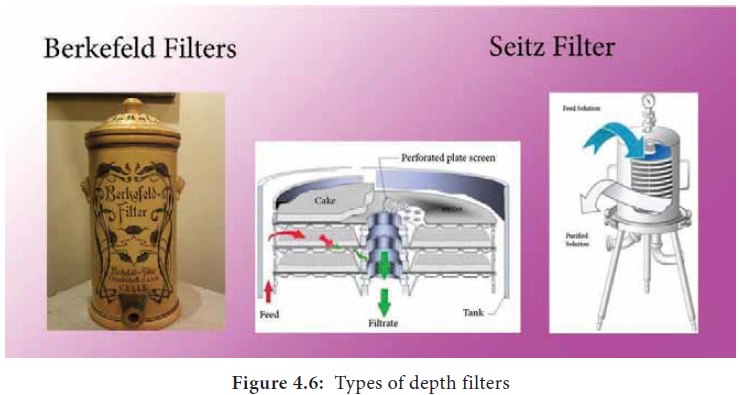

Depth filters

Depth filters are the oldest type of filters and they consist of

overlapping layers of fibrous sheets of paper, asbestos or glass fibers. The

overlapping fibers create

Depth

filter are made up of diatomaceous earth (Berkefeld filters) which are used as

water purifiers. Examples of types of depth filters (Figure 4.6) contains

unglazed porcelain (Chamberl and filters) and asbestos (Seitz Filter).

Air filtration

Air also can be sterilized by filtration.

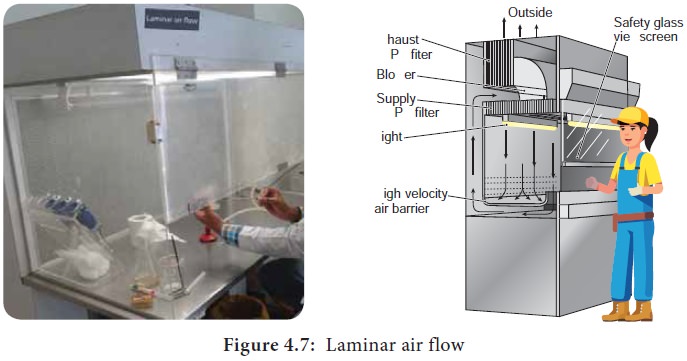

The air is freed from infection by passing it through High

Efficiency Particle Arrester (HEPA) filter. Laminar air flow biological safety

cabinets are one of the most important air filtration systems (Figure 4.7). It

employes HEPA filters which remove 99.97% of 0.33μm particles size. Some

operation theaters and rooms occupied by burn patients receive filtered air to

lower the numbers of airborne microbes. HEPA filters remove almost all microorganisms

above 0.3μm in diameter.

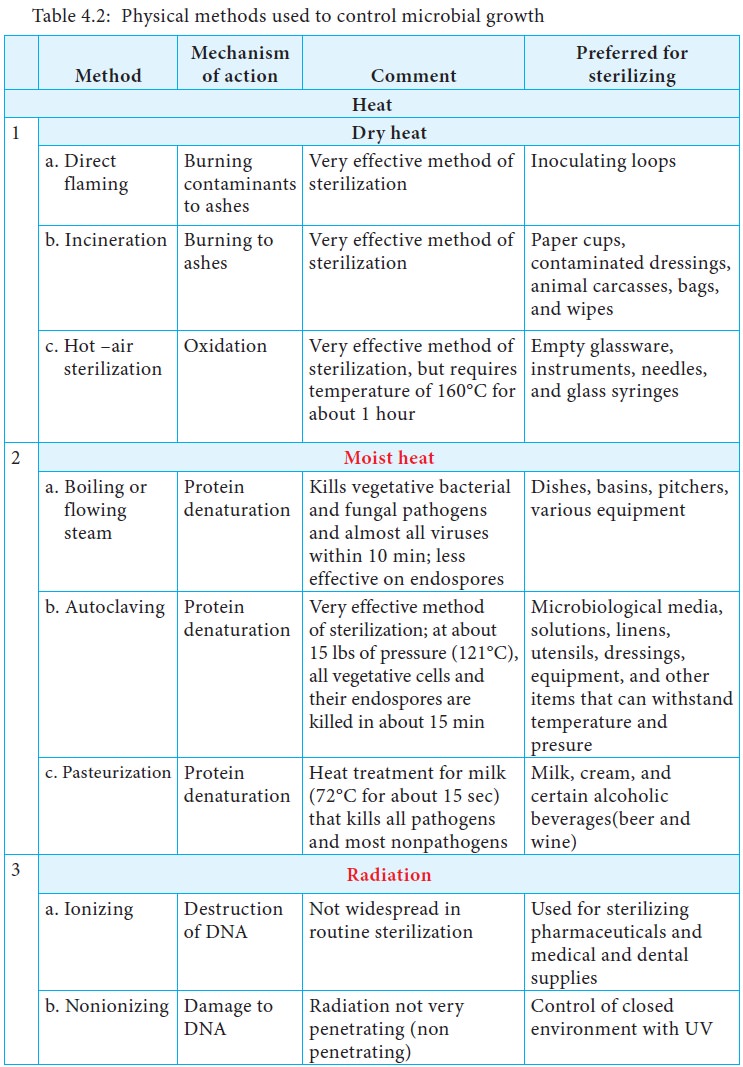

Various physical methods of sterlization is summarized in Table

4.2

Related Topics