Chapter: Transmission and Distribution : Transmission Line Parameters

Spiraling and Bundle Conductor Effect

SPIRALING AND BUNDLE CONDUCTOR

EFFECT

There are

two types of transmission line conductors: overhead and underground. Overhead

conductors, made of naked metal and suspended on insulators, are preferred over

underground conductors because of the lower cost and easy maintenance. Also,

overhead transmission lines use aluminum conductors, because of the lower cost

and lighter weight compared to copper conductors, although more cross-section

area is needed to conduct the same amount of current. There are different types

of commercially available aluminum conductors:

aluminum-conductor-steel-reinforced (ACSR), aluminum-conductor-alloy-reinforced

(ACAR), all-aluminum-conductor (AAC), and all-aluminumalloy- conductor (AAAC).

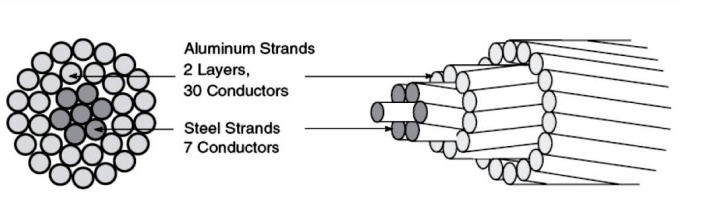

ACSR is

one of the most used conductors in transmission lines. It consists of alternate

layers of stranded conductors, spiraled in opposite directions to hold the

strands together, surrounding a core of steel strands. Figure 13.4 shows an

example of aluminum and steel strands combination. The purpose of introducing a

steel core inside the stranded aluminum conductors is to obtain a high

strength-to-weight ratio. A stranded conductor offers more flexibility and

easier to manufacture than a solid large conductor. However, the total

resistance is increased because the outside strands are larger than the inside

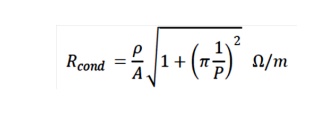

strands on account of the spiraling. The resistance of each wound conductor at

any layer, per unit length, is based on its total length as follows:

Related Topics