Chapter: Mechanical : Design of Transmission Systems : Bevel, Worm and Cross Helical Gears

Solved Problems: Bevel, Worm and Cross Helical Gears

SOLVED PROBLEMS

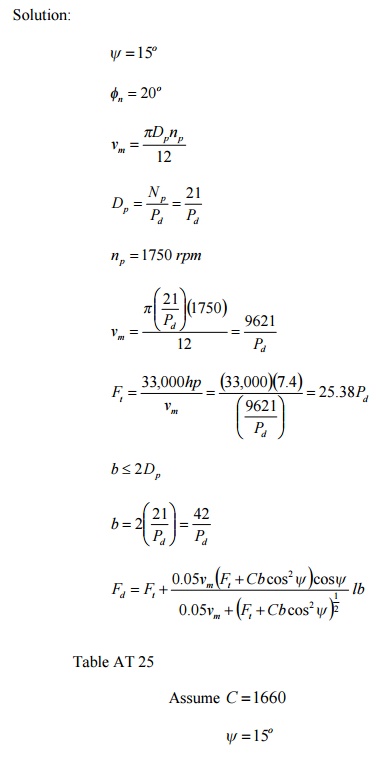

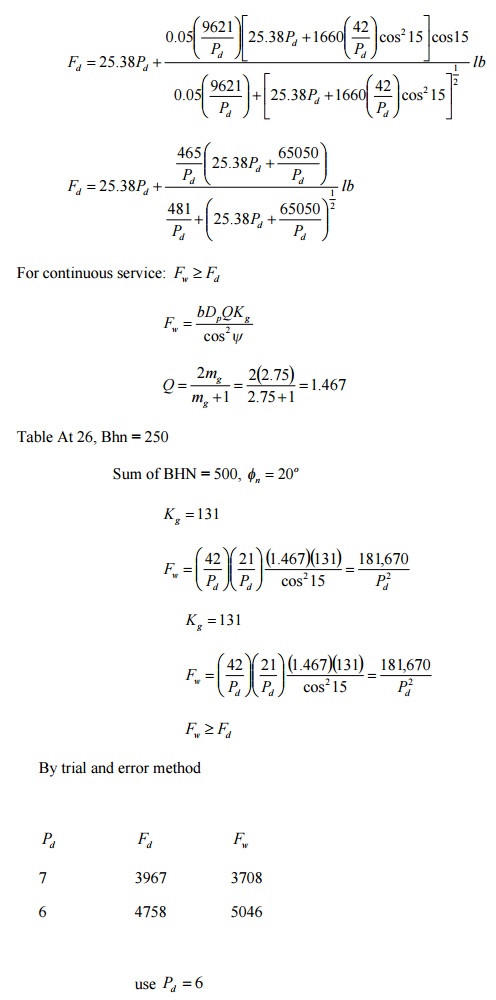

1. For continuous duty in a speed reducer, two helical gears are to be rated at 7.4 hp at a pinion speed of 1750 rpm; mw » 2.75 ; the helix angle 15o ; 20o F.D. teeth in the normal plane; let N p = 21 teeth, and keep b < 2Dp . Determine the pitch, face, N g , and the material and heat treatment. Use through-hardened teeth with a maximum of 250 BHM (teeth may be cut after heat treatment).

Solution:

su = 3(29,892) = 89,676 psi

Use C1050, OQT 1100 F,

su = 122 ksi , BHN = 248 < 250

Ans.

Pd = 6

b = 7 in

N g = mw N p = (2.75)(21) = 58

Material. C1050, OQT 1100 F

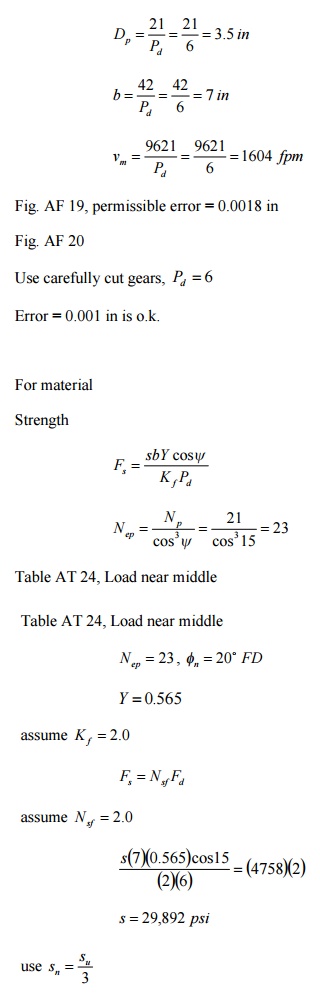

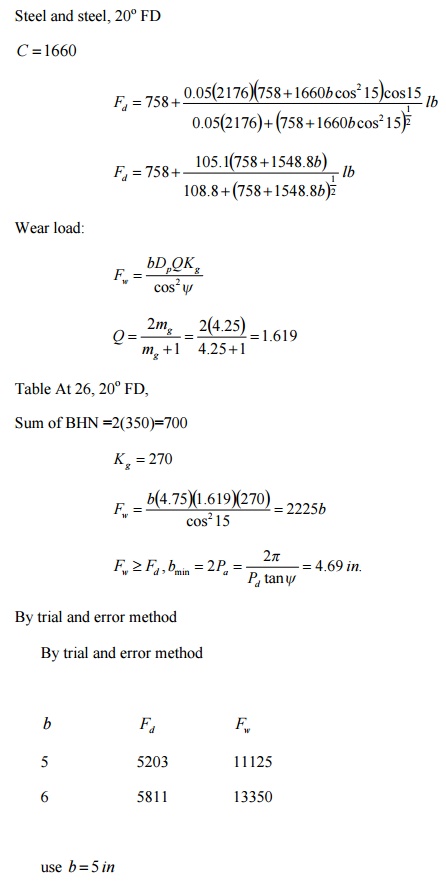

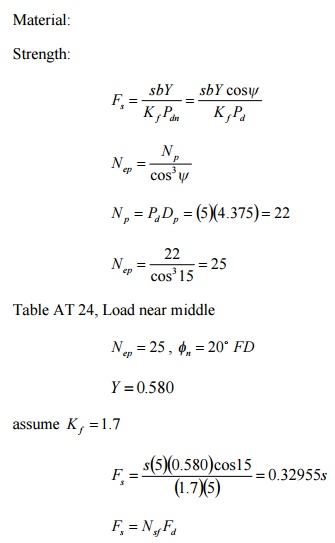

2. A pair of helical gears, subjected to heavy shock loading, is to transmit 50 hp at 1750 rpm of the pinion.; mg y = 15 ; minimum Dp = 4 3/4 in. ; continuous service, 24 hr/day; 20o F.D. teeth in the normal plane, carefully cut; through-hardened to a maximum BHN = 350. Decide upon the pitch, face width, material and its treatment.

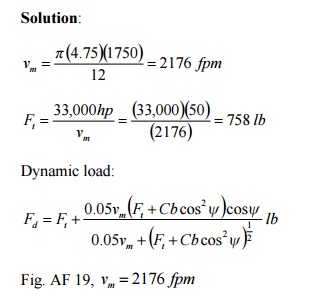

Solution:

Fig. AF 19, vm = 2176 fpm

Permissible error = 0.0014 in

Use carefully cut gears, e = 0.001in , Pd = 5 as standard

Table AT 25,

Steel and steel, 20o FD

C = 1660

for 24 hr/day service, heavy shock loading

Nsf = 1.75

0.32955s = (1.75)(5203)

s = 27,629 psi

use sn = su 3

![]()

su = 3(27,629) = 82,887 psi

Table AT 9

Use 4150, OQT 1200 F,

su = 159ksi , BHN = 331< 350

Ans.

Pd = 5

b = 5 in

Material. 4150, OQT 1200 F

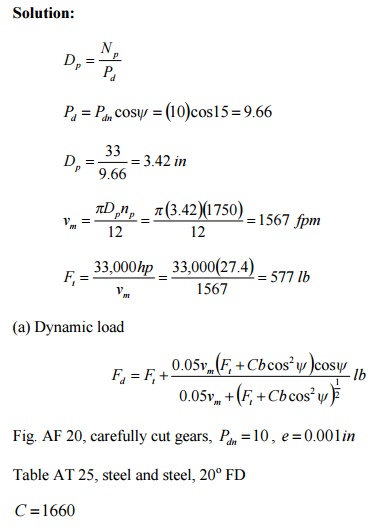

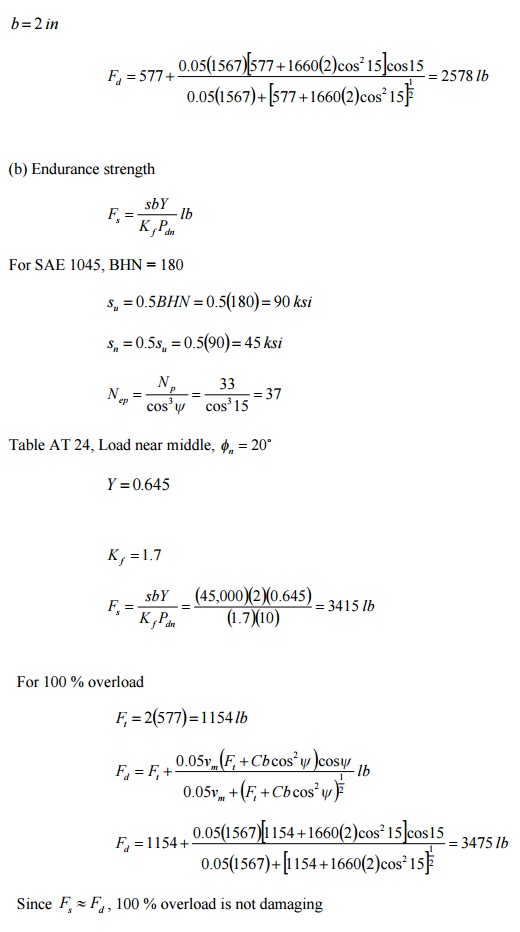

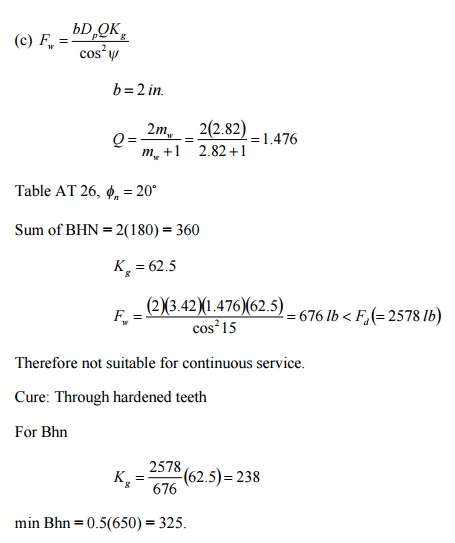

Two helical gears are used in a single reduction speed reducer rated at 27.4 hp at a motor speed of 1750 rpm; continuous duty. The rating allows an occasional 100 % momentary overload. The pinion has 33 teeth. Pdn = 10 , b = 2 in. , fn = 20 , y = 20 , mw = 2.82 . For both gears, the teeth are carefully cut from SAE 1045 with BHN = 180. Compute (a) the dynamic load, (b) the endurance strength; estimate K f = 1.7 . Also decide whether or not the 100 % overload is damaging. (c) Are these teeth suitable for continuous service? If they are not suitable suggest a cure. (The gears are already cut.)

Solution:

Related Topics