Types of Sleeves, Types of Sleeve Finishes, Summary | Sewing Garment - Sleeves | 11th Textiles and Dress Designing : Chapter 13 : Sewing Garment Details

Chapter: 11th Textiles and Dress Designing : Chapter 13 : Sewing Garment Details

Sleeves

SLEEVES

Introduction

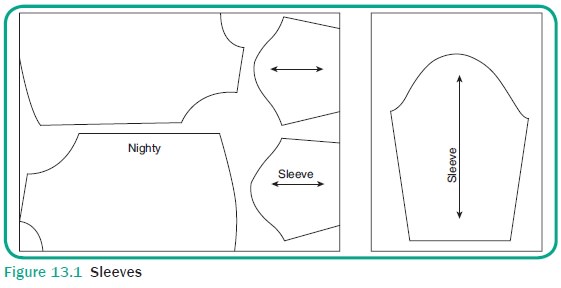

Sleeve is a part of the upper garment. It is

attached to bodice at the armhole. Sleeves add grace and beauty to any

gar-ment. Sleeves can be modified to suit wearers figure. There are different

types of sleeves. Some are close fitting and oth-ers are stitched with fullness.

The length of sleeve can be changed to create short, elbow sleeve, three forth

sleeve and full sleeves. Colour, texture, shape and size of sleeves can also be

changed to create sleeve variations. Sleeves are generally cut along straight

grain, but to create vari-ation, it can be cut on cross grain also (Figure

13.1.).

Types of Sleeves

Sleeves vary depending upon type of gar-ment, the fabric used, one’s preferences and needs. The length of the sleeve and fullness in sleeves can be altered, to create new designs.

Parts of Sleeve

·

Cap line – around the arm, where the arm is

separated from the body.

·

Side seam – where the sleeve is joined to form a

tubular structure.

·

Hem line – finished edge of the sleeve.

·

Upper sleeve round – around the fullest part of

sleeve.

·

Elbow round – around the fullest part of elbow.

·

Wrist round – around the part of the arm where

the palm starts.

Sleeves are classified as set in sleeve and open

construction sleeve based upon the method of sewing. Set in sleeves are sleeves

in which the side seams are attached to form a circular structure. Then it is

attached to the bodice front and back which has to set into the armhole of

bodice blocks. Therefore it is known as set in sleeve.

Example: Sari blouse.

Open construction sleeves are sleeves in which

the sleeve is first attached to the armscye of the bodices front and back. Then

the sleeves and bodices side seams are stitched as a straight line.

Example: Men’s shirt sleeve.

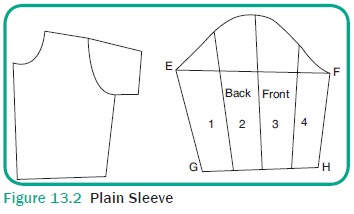

Plain Sleeve

This is also known as basic sleeve. It is used in

all garments and more popular in sari blouses. It is plain without any fullness

and fits correctly around the armscye and falls over the upper arm. The length

of the sleeve varies depend-ing upon the designers taste (Figure 13.2).

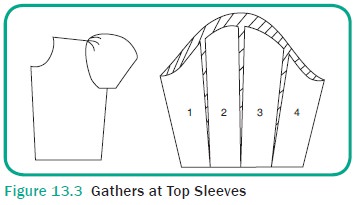

Gathered Sleeves

Gathered Sleeves is a type of sleeve which is

also called puff sleeve. It is mostly used in dresses and women’s blouses. It

has fullness either at the top edge or at both, the top and bottom of sleeve

part. The drafting pattern for sleeves with gathers at the top is prepared

using the basic sleeve pattern. The top of the sleeve is slashed almost till

the bottom hem line. The pattern is placed over another sheet of paper with the

slashed parts spread open according to the amount of gathers required with 3 to

5 cm. extra on top for puffing. The outline is drawn on the new sheet and the

pattern is cut (Figure 13.3). The process is reversed for puff at bottom.

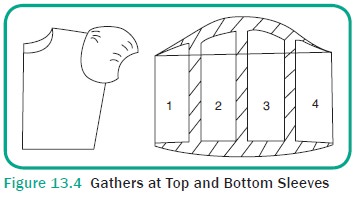

For sleeves with gathers at both the top and the

bottom, the basic sleeve pattern is slashed till the bottom edge of the sleeve.

The four parts of the sleeves are spread apart on a new sheet with the sleeve

cap in line. The patterns are placed with 3 to 5 cm extra at top and at the

bottom for puffing. Sometimes, the bottom is not gathered and left loose for

fullness (Figure 13.4).

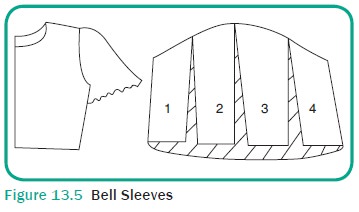

Bell Sleeves

Bell sleeve is also prepared with the pattern of

the basic sleeve. The pattern is slashed from the bottom edge (and spread) from

the bottom edge to the maximum, for extra fullness. The pattern is drawn on a

new sheet and cut. The lower edge is left loose for fullness (Figure 13.5).

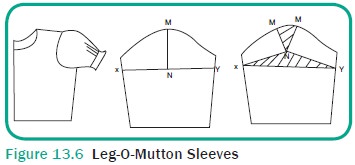

Leg-0-mutton Sleeve

Leg -0-mutton sleeve is puffed at the top and the

bottom is tight fitted with gathers. It is also prepared with the basic sleeve

pattern. The pattern is cut at the middle of the sleeve horizontally; then a

vertical slash is made on the top edge and spread apart. This is kept on a new

sheet and a new pattern is drawn and cut (Figure 13.6).

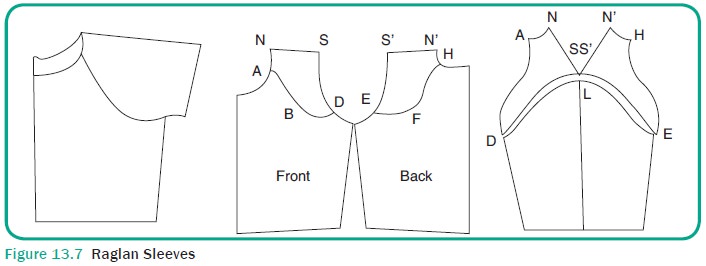

Raglan Sleeve

Raglan sleeve is mostly used for sports-wear,

kids wear, T-shirt. It does not have any armhole seam and shoulder seam. Raglan

sleeve is also prepared with the basic sleeve and extension are added to the

bodies from and back patterns to draft the final raglan sleeve pattern.

Mark point D, 2.5cm above the under arm and A,

2.5cm away from the shoulder point. A and D are joined with a curve as in the

figure. The same proce-dure is followed to draw the curve EFH on bodies back.

The top pattern of the bodice is along the curves ABD and EFH. Drawn patterns

are placed on a new sheet with the basic sleeve pattern at the bottom, matching

the centre point of the pattern. Mark the shoulder points as S and S1 on the

bodice front and back. Match them to center of the sleeve point ‘L’. Draw the

out-line for raglan sleeve pattern. This sleeve is stitched with seam that runs

from the neck line to the armhole line (Figure 13.7).

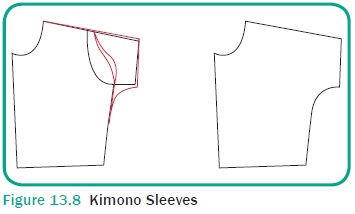

Kimono Sleeve

Kimono sleeves are mostly used in gar-ments where

more comfort is needed. It is used mostly for sportswear, kids wear, dance

costume and ladies tops. In kimono sleeve there is no seam either at the

armhole or in the shoulder. The pattern of the sleeves is cut together with the

bodice. Thus the sleeves run from the side seam of sleeve to the side seam of

the bodice (Figure 13.8)

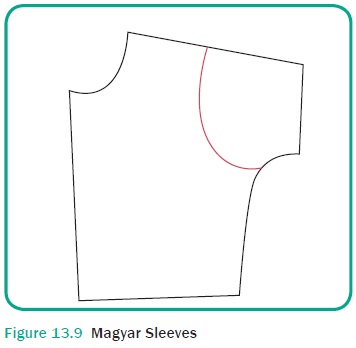

Magyar Sleeve

Magyar sleeve is also like kimono sleeve where

the bodice pattern is extended from the shoulder line approximately 5 cm

outside from the highest point of the shoulder. Lower arm circumference is

drawn perpendicular to the bodice pat-tern and attached at the edge of the

pat-tern (Figure 13.9).

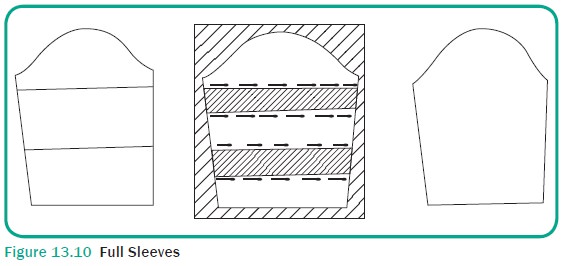

Full Sleeve

A full sleeve pattern is an extension of the

basic sleeve pattern but the length of the sleeve is extended till the wrist.

The circumference of the sleeve is changed accordingly. Full sleeves are used

mostly in women’s wear, kurtas and men’s shirt. In men’s shirt, these sleeves

are finished with a cuff at the lower edges (Figure 13.10).

The basic sleeve pattern is cut horizon-tally and

spread to get the required length.

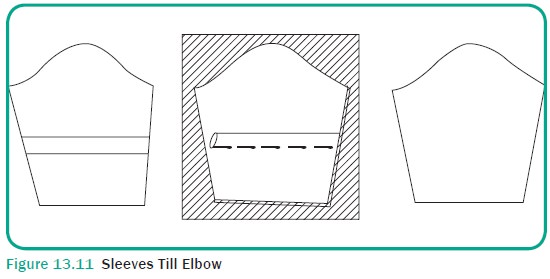

Sleeves Till Elbow / ¾ Sleeves

Three fourth sleeve is also an extension of the

plain sleeve where the lower edge of the sleeve is extended till the length of

the elbow of the wearer. The circumfer-ence is changed according to the wearers

taste. Three fourth sleeves are sometimes gathered at the lower edge or left loose.

These sleeves are used mainly in wom-en’s wears, kameez tops and kids wear,

(Figure 13.11).

Types of Sleeve Finishes

For the perfect completion of a sleeve,

dif-ferent finishes are used on the sleeve edge.

The selection of the finish usually depends upon

the pattern of the sleeve. The differ-ent types of sleeve finishes are as

follows :

·

Self-hemmed edge – It is a simple sleeve finish.

A facing may be used in it.

·

Double binding edge – It gives a decorative

finish to the sleeve. It can also be made with contrasting fabric for interest

creation in the garment.

·

Casing – It is sewn at the edge of the sleeve. It

can either be self faced or can be separately applied.

·

Cuff – it is stitched at the edge of the sleeve.

It can be with a placket open-ing or can be loose without opening (Figure

13.12).

Cuff :

A cuff is a sleeve finish given at the sleeve

edge. A cuff can be straight, gathered or pleated according to the design of

the garment.

Cuff with Plackets:

Cuff with placket is generally attached to a long

sleeve with a placket opening made at the sleeve edge. Thus cuff comes tight

around the wrist, with a placket. There are three types of plackets which are

commonly used.

·

Faced placket – The edges of the placket meet at

the opening.

·

Continuous bound placket – It is finished with a

single fabric strip to create a narrow lap.

·

Tailored or shirt placket – It is fin-ished with

two separate pieces to create a wider lap (Figure 13.13).

Cuffs without Plackets:

Cuffs without plackets have no openings and hence

the sleeve openings are loose for the hands to come out easily. There are three

basic types of cuffs without plackets.

·

Straight band Cuff – It is a simple cuff with a

straight band of fabric attached at the bottom of the sleeve.

·

Straight turn back Cuff – It is made by turning

up the hem of the sleeve. Sometimes, a separate extension piece is added at the

bottom of the sleeve and turned.

·

Shaped turn- back Cuff – This cuff is first

constructed separately with a shape and then the same is stitched to the edge

of the sleeve with a fac-ing (Figure 13.14).

Summary :

Sleeves are attached to the bodice at the

arm-hole. They can be modified to various shapes and sizes. The basic types of

sleeve are plain sleeves, gathered sleeves, bell sleeves, leg-o-mutton sleeve

and raglan sleeve. Different types of finishes can be given to the sleeve edges

like hemmed edge, double binding edge, casing and cuff. Cuff can be attached

with or without plackets.

POINTS TO REMEMBER :

·

Sleeve is a part of the garment which is draped

over the upper arm of a person.

·

Different type of sleeves can be drafted by

increasing or decreasing the length and width of the sleeves and also by adding

fullness.

·

Based upon the method of construction sleeves are

grouped as set-in sleeve and open construction sleeve.

·

Sleeve can be finished with binding, facing,

casing or cuffs.

ACTIVITIES FOR THE TEACHER:

·

Show the different types of sleeves to the

students.

·

Draft the method of basic sleeve pattern and

demonstrate cuff attachment to the sleeve.

·

Demonstrate the stitching of different types of

sleeves.

ACTIVITIES FOR STUDENTS :

·

Collect pictures of different types of sleeves to

prepare an album.

·

Prepare paper patterns for all the sleeve types,

cut and stitch the same to pre-pare an album.

Related Topics