Chapter: Mechanical : Dynamics of Machines : Single Degree Free Vibration

Single Degree Free Vibration

SINGLE DEGREE FREE VIBRATION

1 INTRODUCTION:

When a system is subjected to an initial disturbance and then left free

to vibrate on its own, the resulting vibrations are referred to as free

vibrations . Free vibration occurs

when a mechanical system is set off with an initial input and then allowed to

vibrate freely. Examples of this type of vibration are pulling a child back on

a swing and then letting go or hitting a tuning fork and letting it ring. The

mechanical system will then vibrate at one or more of its "natural

frequencies" and damp down to zero.

2 BASIC ELEMENTS OF VIBRATION

SYSTEM:

Mass or

Inertia

![]()

Springiness

or Restoring element

![]()

Dissipative

element (often called damper)

![]()

External

excitation

![]()

3 CAUSES OF VIBRATION:

Unbalance: This is basically in reference to

the rotating bodies. The uneven distribution of mass in a rotating body contributes to the unbalance. A good

example of unbalance related vibration would be the

―vibrating alert‖ in our mobile phones. Here a small amount of unbalanced

weight is rotated by a motor causing the vibration which makes the mobile phone

to vibrate. You would have experienced the same sort of vibration occurring in

your front loaded washing machines that tend to vibrate during the

―spinning‖ mode.

Misalignment: This is an other major cause of

vibration particularly in machines that are

driven by motors or any other prime movers.

Bent

Shaft: A

rotating shaft that is bent also produces the the vibrating effect since it losses it rotation capability about

its center.

Gears in

the machine: The gears in the machine always tend to produce

vibration, mainly due to their

meshing. Though this may be controlled to some extent, any problem in the

gearbox tends to get enhanced with ease.

Bearings: Last but not the least, here is a

major contributor for vibration. In majority of the cases every initial problem starts in the bearings and

propagates to the rest of the members of the machine. A bearing devoid of

lubrication tends to wear out fast and fails quickly, but before this is

noticed it damages the remaining components in the machine and an initial look

would seem as if something had gone wrong with the other components leading to

the bearing failure.

Effects of vibration:

(a)Bad Effects:

The presence of vibration in any mechanical system

produces unwanted noise, high stresses, poor reliability, wear and premature

failure of parts. Vibrations are a great source of human discomfort in the form

of physical and mental strains.

(b)Good Effects:

A vibration does useful work in musical

instruments, vibrating screens, shakers, relive pain in physiotherapy.

4 METHODS OF REDUCTION OF VIBRATION:

¨ -unbalance

is its main cause, so balancing of parts is necessary.

¨ -using

shock absorbers.

¨ -using

dynamic vibration absorbers.

¨ -providing

the screens (if noise is to be reduced)

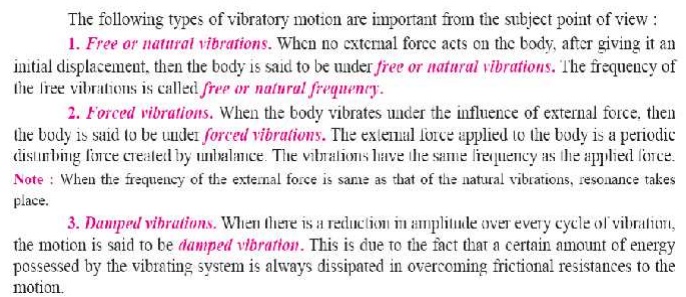

5 TYPES OF VIBRATORY MOTION:

¨ Free

Vibration

¨ Forced

Vibration

6 TERMS USED VIBRATORY MOTION:

(a)Time period (or)period of

vibration:

It is the time taken by a vibrating body to repeat

the motion itself.time period is usually expressed in seconds.

(b) Cycle:

It is the

motion completed in one time period.

(c) Periodic motion:

A motion

which repeats itself after equal interval of time.

(d)Amplitude (X)

The maximum displacement of a vibrating body from

the mean position.it is usually expressed in millimeter.

(e) Frequency (f)

The

number of cycles completed in one second is called frequency

7 DEGREES OF FREEDOM:

The minimum number of independent coordinates required to specify the

motion of a system at any instant is known as D.O.F of the system.

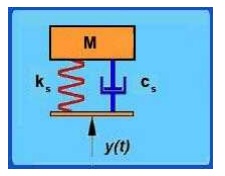

Single degree of freedom system:

The system shown in this figure is what is known as

a Single Degree of Freedom system. We use the term degree of freedom to refer

to the number of coordinates that are required to specify completely the

configuration of the system. Here, if the position of the mass of the system is

specified then accordingly the position of the spring and damper are also

identified. Thus we need just one coordinate (that of the mass) to specify the

system completely and hence it is known as a single degree of freedom system.

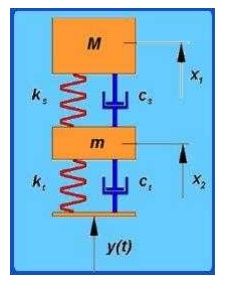

Two degree of freedom system:

A two degree of freedom system With reference to

automobile applications, this is referred as ―quarter car‖ model. The

bottom mass refers to mass of axle, wheel etc components which are below the

suspension spring and the top mass refers to the mass of the portion of the car

and

passenger.

Since we need to specify both the top and bottom mass positions to completely

specify the system, this becomes a two degree of freedom system.

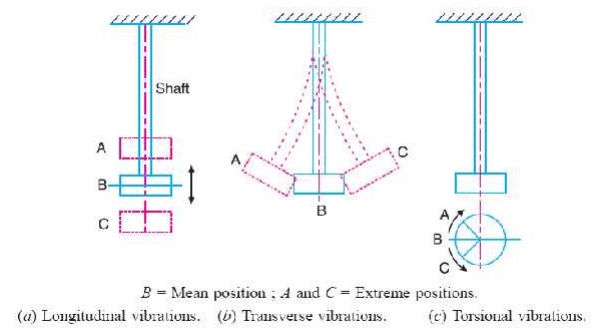

8 TYPES OF VIBRATORY MOTION:

Types of Vibration:

(a)Longitudinal vibration (b)Transverse Vibration (

c)Torsional Vibration.

Longitudinal Vibration:

When the particles of the shaft or disc moves parallel to the axis of

the shaft, then the vibrations known as longitudinal vibrations.

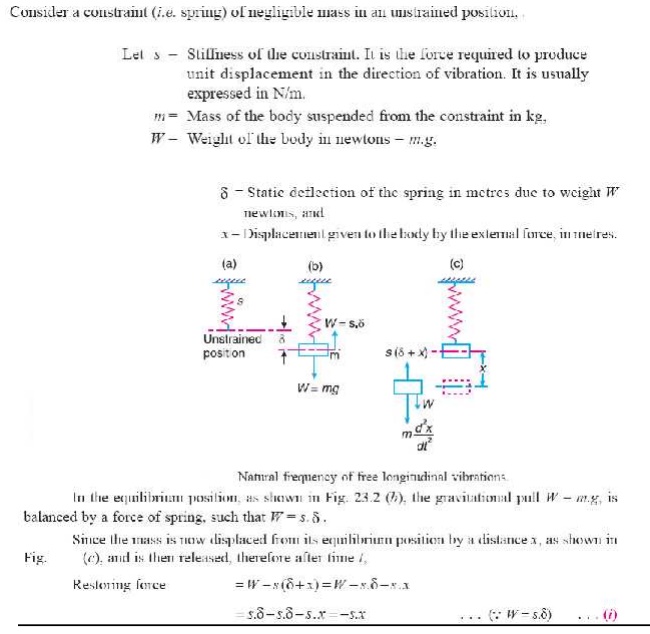

Free undamped longitudinal

vibrations;

When a body is allowed to vibrate on its own, after

giving it an initial displacement, then the ensuring vibrations are known as

free or natural vibrations. When the vibrations take place parallel to the axis

of constraint and no damping is provided, then it is called free undamped

longitudinal vibrations.

9 NATURAL FREQUENCY OF FREE

UNDAMPED LONGITUDINAL VIBRATION:

Equilibrium method or Newton ’ s

method :

Energy Method

In free

vibrations, no energy is transferred into the system or from the system.

Therefore, the total energy (sum of KE and PE)is constant and is same all the

times.

3 Rayleigh’s method

In this method, the maximum kinetic energy at mean

position is made equal to the maximum potential energy at the extreme position.

10 EQUIVALENT STIFFNESS OF

SPRING.

(1) Springs

in series

(2) Springs

in parallel

(3) Combined

springs

(4) Inclined

springs

11 DAMPING:

It is the resistance to the motion of a vibrating

body. The vibrations associated with this resistance are known as damped

vibrations.

Types of damping:

(1) Viscous

damping

(2) Dry

friction or coulomb damping

(3) Solid

damping or structural damping

(4) Slip or

interfacial damping.

Damping Coefficient:

The

damping force per unit velocity is known as damping coefficient.

Equivalent damping coefficient:

Dampers

may be connected either in series or in parallel to provide required damping.

12 DAMPED VIBRATION:

The

vibrations associated with this resistance are known as damped vibrations.

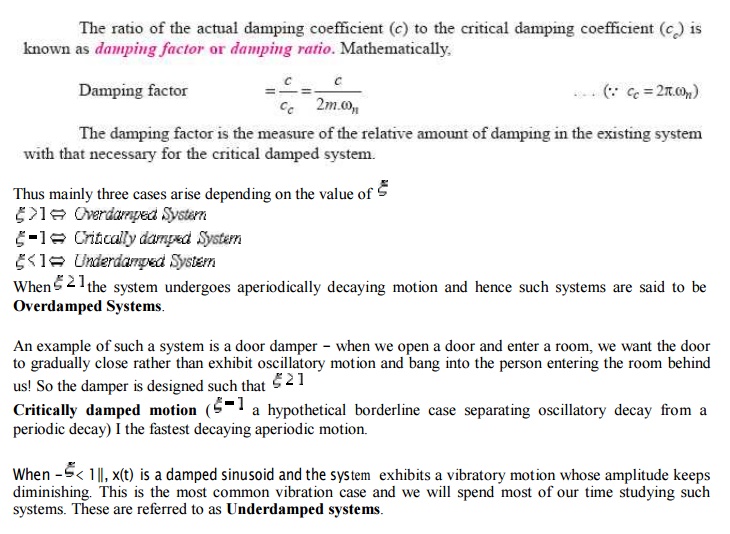

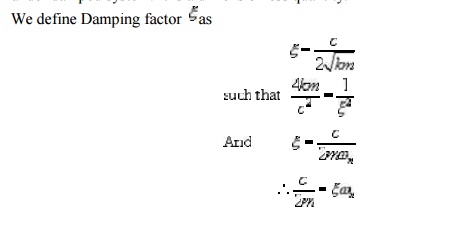

Damping factor:

Damping factor can be defined as the ratio of

actual damping coefficient to critical damping coefficient.

Logarithmic decrement:

It is defined as the natural logarithm of ratio of

any two successive amplitudes of an under damped system. It is a dimensionless

quantity.

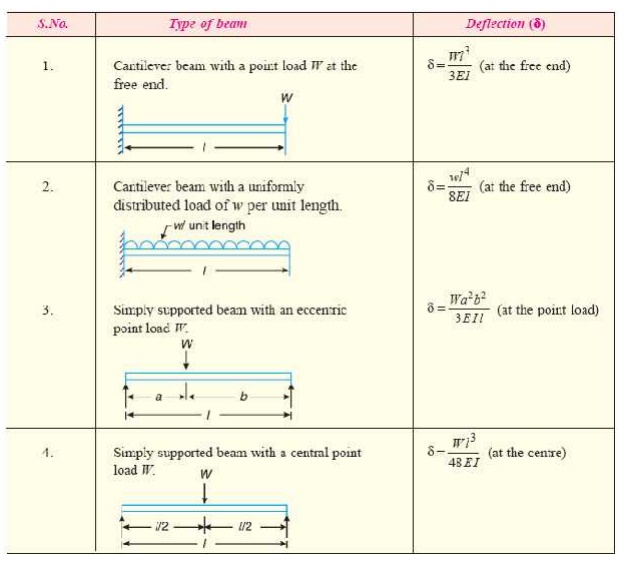

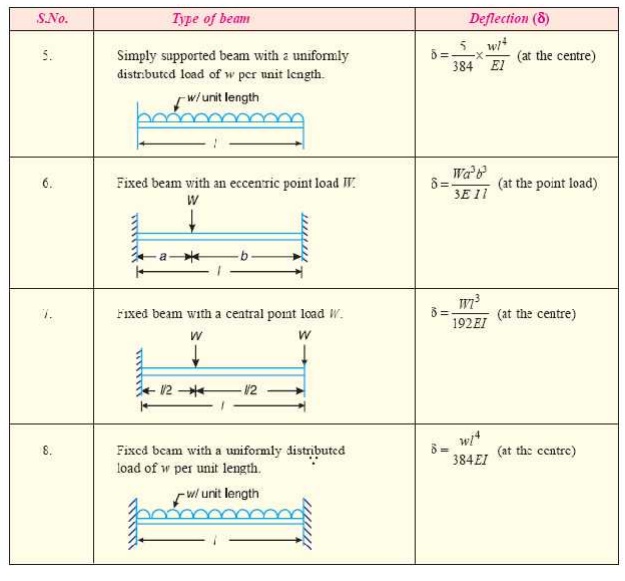

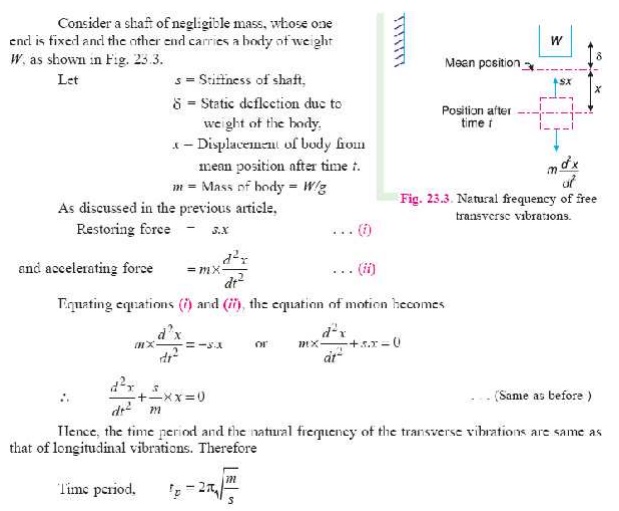

13 TRANSVERSE VIBRATION:

When the particles of the shaft or disc moves

approximately perpendicular to the axis of the shaft, then the vibrations known

as transverse vibrations.

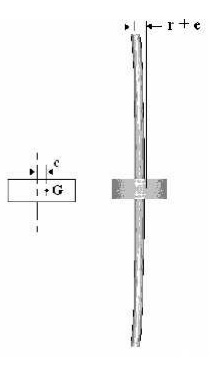

Whirling speed of shaft:

The speed, at which the shaft runs so that the additional deflection of

the shaft from the axis of rotation becomes infinite, is known as critical or

whirling speed.

No shaft can ever be perfectly straight or

perfectly balanced. When an element of mass is a distance from the axis of

rotation, centrifugal force, will tend to pull the mass outward. The elastic

properties of the shaft will act to restore the ―straightness‖. If the

frequency of rotation is equal to one of the resonant frequencies of the

shaft, whirling will occur. In order to save the machine from failure,

operation at such whirling speeds must be avoided.

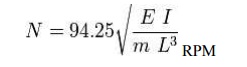

The

whirling frequency of a symmetric cross section of a given length between two

points is

given by:

Where E =

young's modulus, I = Second moment of area, m = mass of the shaft, L= length of

the shaft between points

A shaft

with weights added will have an angular velocity of N (rpm) equivalent as

follows:

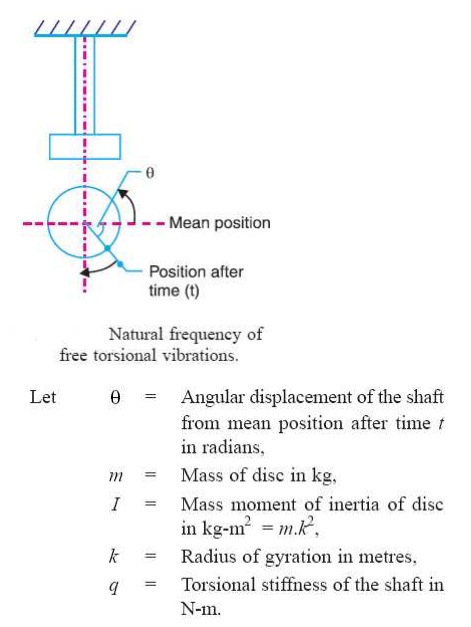

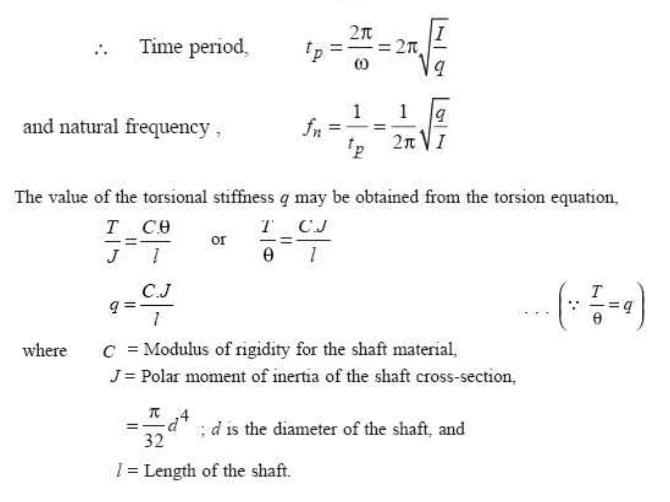

14 TORSIONAL VIBRATION:

When the

particles of the shaft or disc move in a circle about the axis of the shaft,

then the vibrations known as tensional vibration

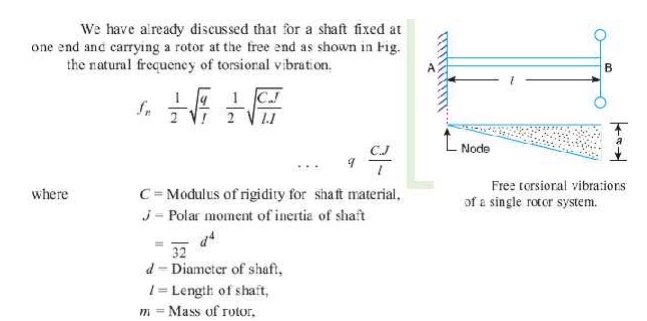

Torsional vibration of a single rotor system:

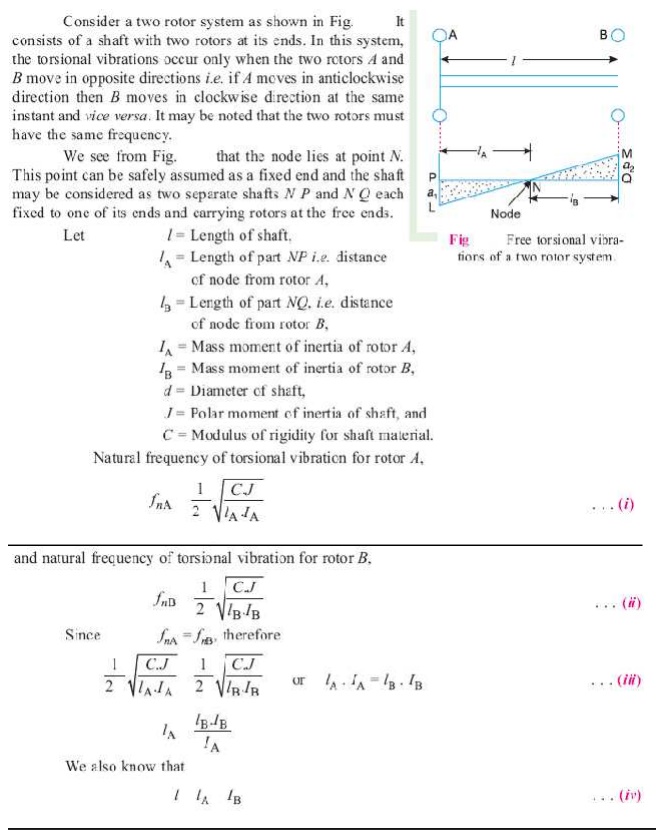

Torsional vibration of a two rotor system:

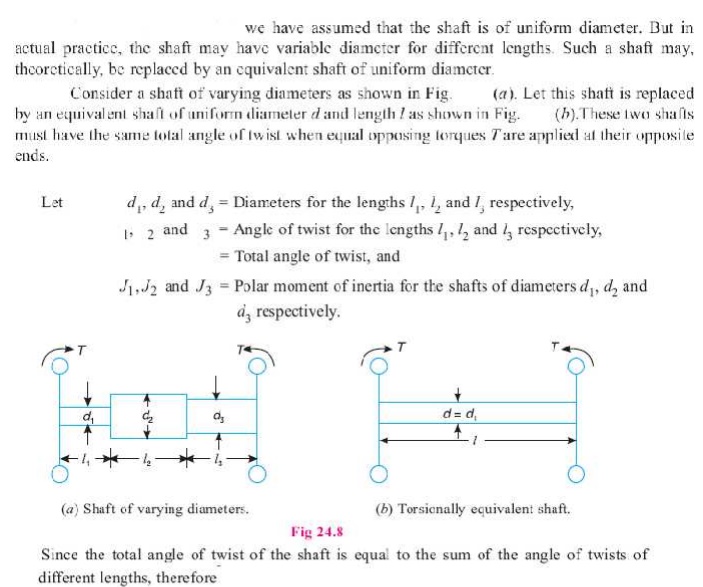

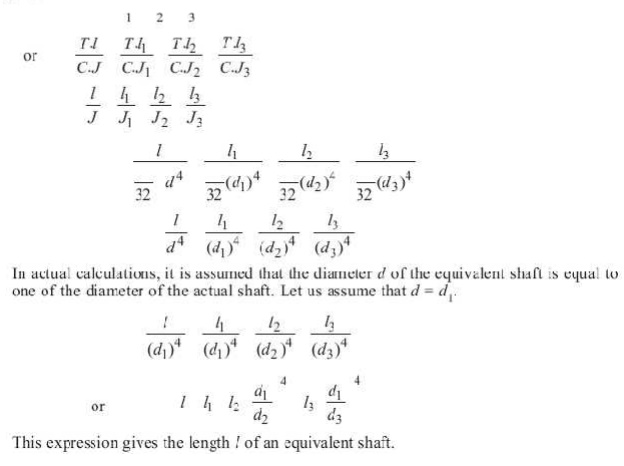

Torsionally equivalent shaft:

Related Topics