Chapter: Mechanical : Dynamics of Machines : Single Degree Free Vibration

Solved Problems: Single Degree Free Vibration

SOLVED PROBLEMS

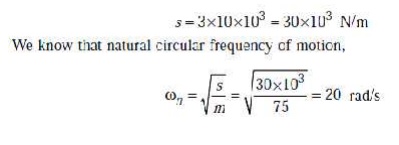

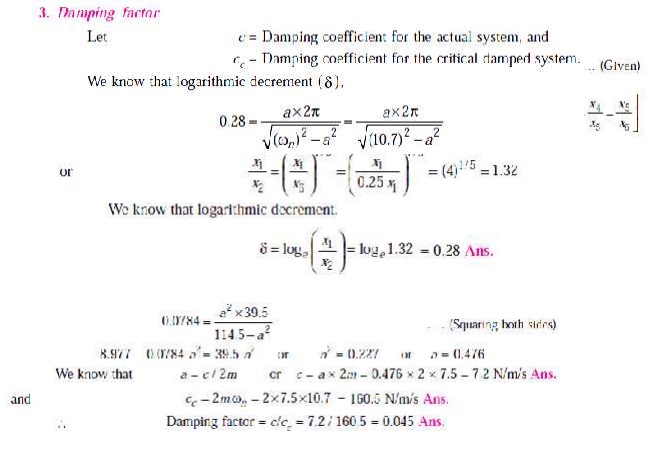

1. A

machine of mass 75 kg is mounted on springs and is fitted with a dashpot to

damp out vibrations. There are three springs each of stiffness 10 N/mm and it

is found that the amplitude of vibration diminishes from 38.4 mm to 6.4 mm in

two complete oscillations. Assuming that the damping force varies as the

velocity, determine : 1. the resistance of the dash-pot at unit velocity ; 2.

the ratio of the frequency of the damped vibration to the frequency of the undamped

vibration ; and 3. the periodic time of the

![]()

![]() damped

vibration.

damped

vibration.

Solution.

Given : m

= 75 kg ; s = 10 N/mm = 10 ×103 N/m ; x1 = 38.4 mm = 0.0384 m ; x3 = 6.4 mm = 0.0064 m

![]() Since

the stiffness of each spring is 10 × 103 N/m and there are 3

springs, therefore total stiffness,

Since

the stiffness of each spring is 10 × 103 N/m and there are 3

springs, therefore total stiffness,

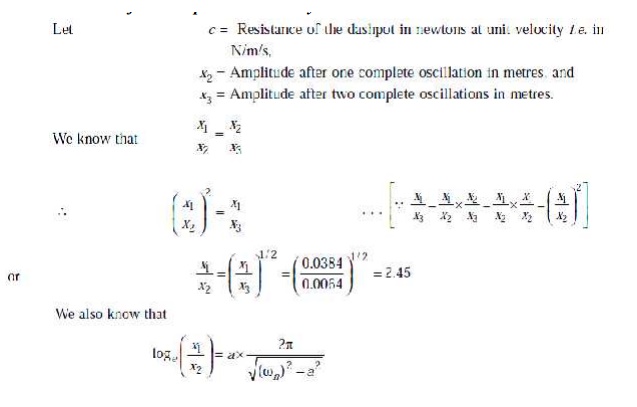

1. Resistance

of the dashpot at unit velocity

2. Ratio of the frequency of the damped

vibration to the frequency of undamped vibration

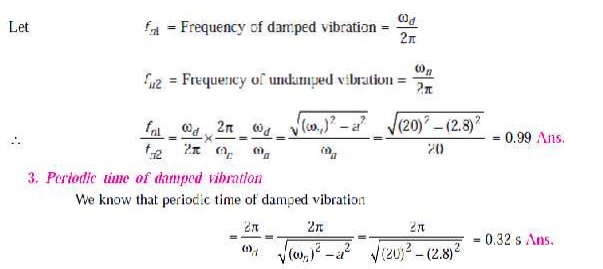

2. The mass of a single degree damped vibrating

system is 7.5 kg and makes 24 free oscillations in 14 seconds when disturbed

from its equilibrium position. The amplitude of vibration reduces to 0.25 of

its initial value after five oscillations. Determine : 1. stiffness of the

spring, 2. logarithmic decrement, and 3. damping factor, i.e. the ratio of the

system damping to critical damping.

![]()

![]()

Solution.

Given : m

= 7.5 kg

Since 24 oscillations are made in 14 seconds,

therefore frequency of free vibrations,

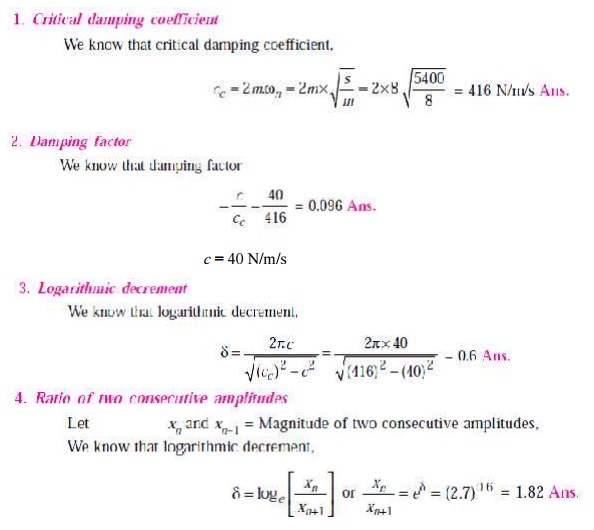

3(i) The measurements on a mechanical vibrating

system show that it has a mass of 8 kg and that the springs can be combined to

give an equivalent spring of stiffness 5.4 N/mm. If the vibrating system have a

dashpot attached which exerts a force of 40 N when the mass has a velocity of 1

m/s, find : 1. critical damping coefficient, 2. damping factor, 3. logarithmic

decrement, and 4. ratio of two consecutive amplitudes.

![]()

![]()

![]()

Solution. Given : m

= 8 kg ; s = 5.4 N/mm = 5400 N/m

Since the force exerted by dashpot is 40 N, and

the mass has a velocity of 1 m/s , therefore Damping coefficient (actual),

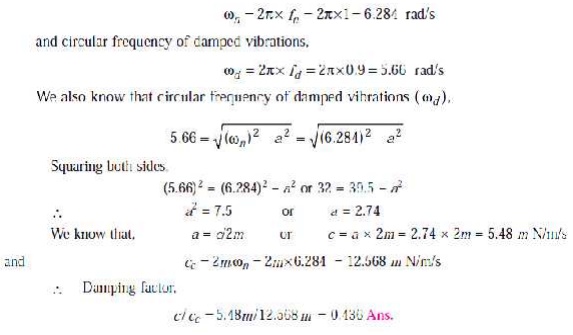

3 (ii) An

instrument vibrates with a frequency of 1 Hz when there is no damping. When the

damping is provided, the frequency of damped vibrations was observed to be 0.9

Hz. Find 1. the damping factor, and 2. logarithmic decrement.

Solution. Given : fn

= 1 Hz ; fd = 0.9 Hz

1.

Damping factor

Let m = Mass

of the instrument in kg,

c = Damping

coefficient or damping force per unit

cc= velocity in N/m/s, and Critical damping coefficient in N/m/s.

We know that natural circular frequency of

undamped vibrations,

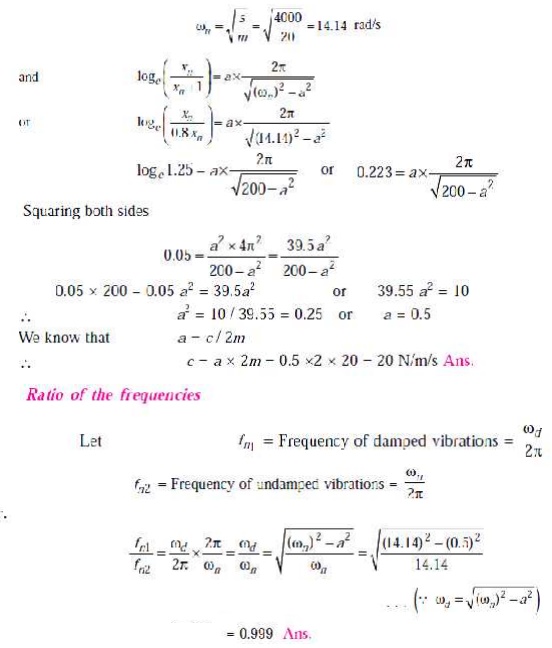

4(i) A coil of spring stiffness 4

N/mm supports vertically a mass of 20 kg at the free end. The motion is

resisted by the oil dashpot. It is found that the amplitude at the beginning of

the fourth cycle is 0.8 times the amplitude of the previous vibration.

Determine the damping force per unit velocity. Also find the ratio of the

frequency of damped and undamped vibrations.

![]()

![]()

![]()

Solution.

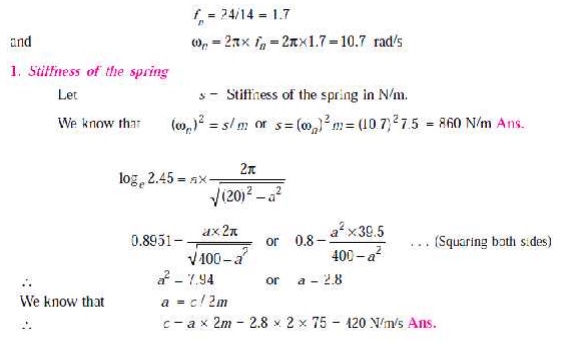

Given : s

= 4 N/mm = 4000 N/m ; m

= 20 kg

![]()

Damping force per unit velocity

Let c

= Damping force in newtons per unit velocity i.e. in N/m/s

xn

= Amplitude at the beginning of the third cycle,

xn+1 =

Amplitude at the beginning of the fourth cycle = 0.8 xn We know that natural circular frequency of motion,

4(ii) Derive an expression for the natural

frequency of single degrees of freedom system.

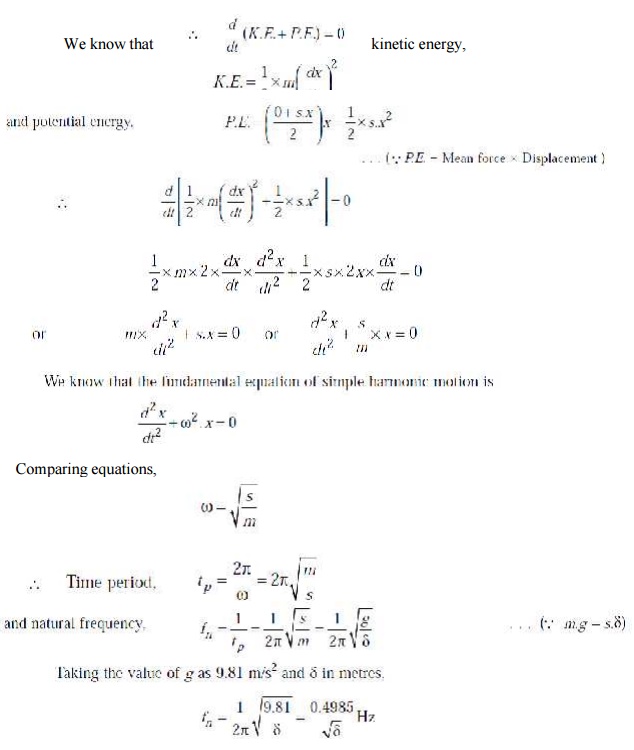

We know that the kinetic energy is due to the

motion of the body and the potential energy is with respect to a certain datum

position which is equal to the amount of work required to move the body from

the datum position. In the case of vibrations, the datum position is the mean

or equilibrium position at which the potential energy of the body or the system

is zero.

In the free vibrations, no energy is transferred

to the system or from the system. Therefore the summation of kinetic energy and

potential energy must be a constant quantity which is same at all the times. In

other words,

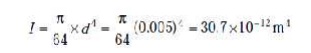

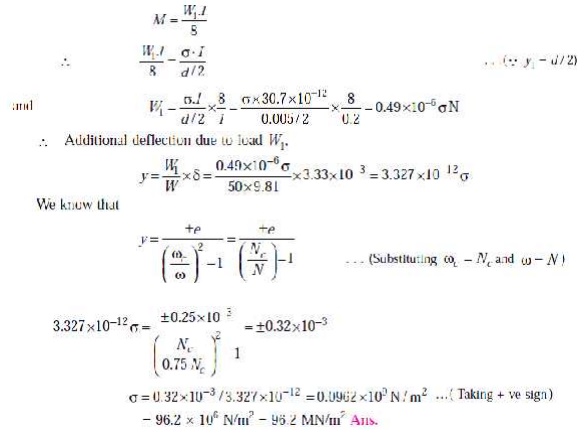

5. A vertical shaft of 5 mm diameter is 200 mm long

and is supported in long bearings at its ends.

A disc of mass 50 kg is attached to the centre of the shaft. Neglecting any

increase in stiffness due to the attachment of the disc to the shaft, find the

critical speed of rotation and the maximum bending stress when the shaft is rotating

at 75% of the critical speed. The centre of the disc is 0.25 mm from the

geometric axis of the shaft. E = 200 GN/m2.

Solution.

Given : d

= 5 mm = 0.005 m ; l

= 200 mm = 0.2 m ; m

= 50 kg ; e = 0.25 mm = 0.25 × 10–3 m ; E = 200 GN/m2 = 200 × 109

N/m2

Critical speed of rotation

We know that moment of inertia of the shaft,

Since the shaft is supported in long bearings,

it is assumed to be fixed at both ends. We know that the static deflection at

the centre of the shaft due to a mass of 50 kg,

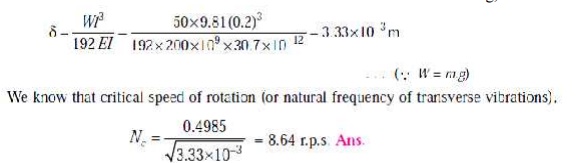

Maximum bending stress

Let σ = Maximum

bending stress in N/m2, and

N

= Speed of the shaft = 75% of critical speed =

0.75 Nc . . . (Given)

When the shaft starts rotating, the additional

dynamic load (W1) to which the shaft

is subjected, may be obtained by using the bending equation,

We know that for a shaft fixed at both ends and

carrying a point load (W1) at the

centre, the maximum bending moment

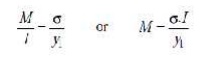

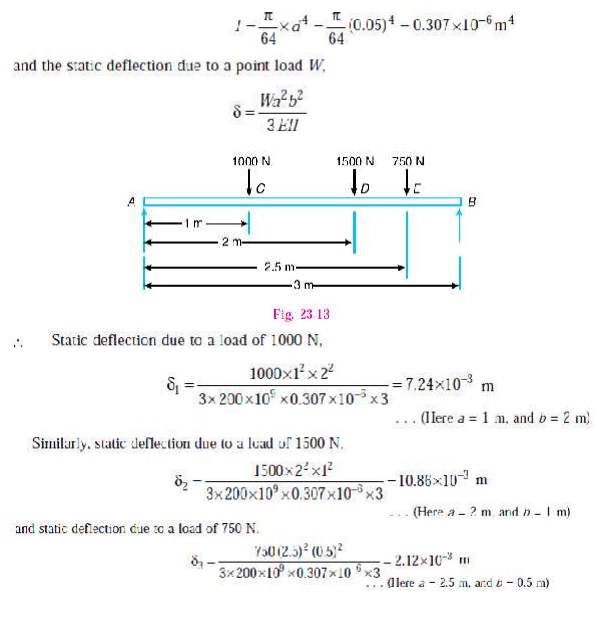

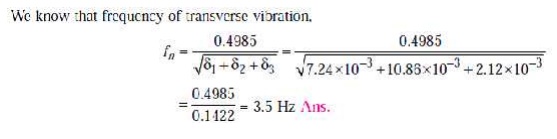

6.(i) A shaft 50 mm diameter and

3 metres long is simply supported at the ends and carries three loads of 1000

N, 1500 N and 750 N at 1 m, 2 m and 2.5 m from the left support. The Young's

modulus for shaft material is 200 GN/m2. Find the frequency of transverse

vibration.

![]()

![]()

![]()

Solution.

Given : d

= 50 mm = 0.05 m ; l

= 3 m, W1 = 1000 N ; W2 = 1500 N ; W3 = 750 N; E = 200 GN/m2 = 200 × 109 N/m2

![]() The

shaft carrying the loads is shown in Fig. 23.13 We know that moment of inertia

of the shaft,

The

shaft carrying the loads is shown in Fig. 23.13 We know that moment of inertia

of the shaft,

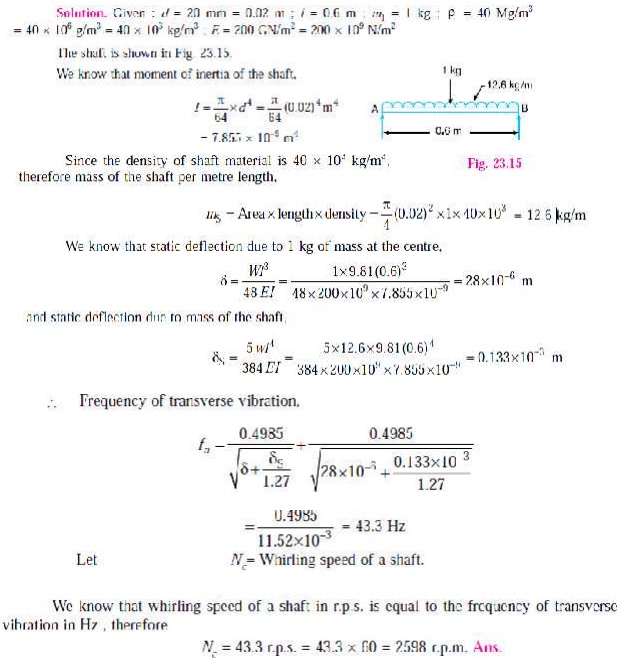

6.(ii) Calculate the whirling speed of a shaft 20

mm diameter and 0.6 m long carrying a mass of 1 kg at its mid-point. The

density of the shaft material is 40 Mg/m3, and Young’s modulus is

200 GN/m2. Assume the shaft to be freely supported.

TUTORIAL PROBLEMS

1.

A beam of length 10 m carries two loads of mass 200

kg at distances of 3 m from each end

together with a central load of mass 1000 kg. Calculate the frequency of

transverse vibrations. Neglect the mass of the beam and take I = 109 mm4 and E = 205×10 3 N/mm2.

[Ans. 13.8 Hz]

13.8

2.

A vertical shaft 25 mm diameter and 0.75 m long is

mounted in long bearings and carries

a pulley

of mass

10 kg midway between the bearings. The centre of pulley is 0.5 mm from the axis

of the shaft. Find (a) the whirling

speed, and (b) the bending stress in

the shaft, when it is rotating at 1700 r.p.m. Neglect the mass of the shaft and

E = 200 GN/m2.

[Ans. 3996 r.p.m ; 12.1 MN/m2]

3. A shaft of 100 mm diameter and 1 metre long is

fixed at one end and the other end carries a

flywheel

of mass 1 tonne. The radius of gyration of the flywheel is 0.5 m. Find the

frequency of torsional vibrations, if the modulus of rigidity for the shaft

material is 80 GN/m2. [Ans. 8.9 Hz]

4.The two

rotors A and B are attached to the end of a shaft 500 mm long. The mass of the

rotor A is 300 kg and its radius of gyration is 300 mm. The corresponding

values of the rotor B are 500 kg and 450 mm respectively. The shaft is 70 mm in

diameter for the first 250 mm ; 120 mm for the next 70 mm and 100 mm diameter

for the remaining length. The modulus of rigidity for the shaft material is 80

GN/m2. Find : 1. The position of the node, and 2. The frequency of

torsional vibration. [Ans. 225 mm from A ; 27.3 Hz]

Related Topics