Chapter: Mechanical : Manufacturing Technology : Shaper, Milling and Gear Cutting Machines

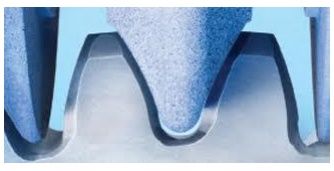

Shaping with a pinion-shaped cutter

Shaping with a pinion-shaped cutter

This modification of the gear

shaping process is defined as a process for generating gear teeth by a rotating

and reciprocating pinion-shaped cutter:

The cutter axis is parallel to

the gear axis. The cutter rotates slowly in timed relationship with the gear

blank at the same pitch-cycle velocity, with an axial primary reciprocating

motion; to produce the gear teeth. A train of gears provides the required

relative motion between the cutter shaft and the gear-blank shaft. Cutting may

take place either at the down stroke or upstroke of the machine. Because the

clearance required for cutter travel is small, gear shaping is suitable for

gears that are located close to obstructing surfaces such as flanges. The tool

is called gear cutter and resembles in shape the mating gear from the conjugate

gear pair, the other gear being the blank.

Gear

shaping is one of the most versatile of all gear cutting operations used to

produce internal gears, external gears, and integral gear-pinion arrangements.

Advantages of gear shaping with pinion-shaped cutter are the high dimensional

accuracy achieved and the not too expensive tool. The process is applied for

finishing operation in all types of production rates.

Finishing

operations

As

produced by any of the process described, the surface finish and dimensional

accuracy may not be accurate enough for certain applications. Several finishing

operations are available, including the conventional process of shaving, and a

number of abrasive operations, including grinding, honing, and lapping.

Related Topics