Chapter: Mechanical : Manufacturing Technology : Shaper, Milling and Gear Cutting Machines

Boring

Boring

Boring is

a process of producing circular internal profiles on a hole made by drilling or

another process. It uses single point cutting tool called a boring bar. In

boring, the boring bar can be rotated, or the workpart can be rotated. Machine

tools which rotate the boring bar against a stationary workpiece are called

boring machines (also boring mills). Boring can be accomplished on a turning

machine with a stationary boring bar positioned in the tool post and rotating

workpiece held in the lathe chuck as illustrated in the figure. In this

section, we will consider only boring on boring machines.

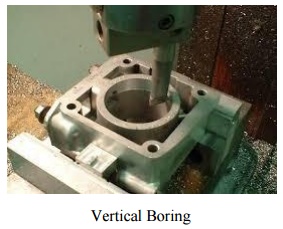

Vertical

Boring

Boring machines

Boring machines can be horizontal

or vertical according to the orientation of the axis of rotation of the machine

spindle. In horizontal boring operation, boring bar is mounted in a tool slide,

which position is adjusted relative to the spindle face plate to machine

different diameters. The boring bar must be supported on the other end when

boring long and small-diameter holes. A vertical boring mill is used for large,

heavy work parts with diameters up to 12 m. The typical boring mill can

position and feed several cutting tools simultaneously. The work part is

mounted on a rotating worktable.

Cutting tool for boring

The typical boring bar is shown

in the figure. When boring with a rotating tool, size is controlled by changing

the radial position of the tool slide, which holds the boring bar, with respect

to the spindle axis of rotation. For finishing machining, the boring bar is

additionally mounted in an adjustable boring head for more precise control of

the bar radial position.

Related Topics