Chapter: Mechanical : Manufacturing Technology : Shaper, Milling and Gear Cutting Machines

Gear milling and Gear hobbing

Gear

Gears can be manufactured by most

of manufacturing processes discussed so far (casting, forging, extrusion,

powder metallurgy, blanking). But as a rule, machining is applied to achieve

the final dimensions, shape and surface finish in the gear. The initial

operations that produce a semi finishing part ready for gear machining as

referred to as blanking operations; the starting product in gear machining is

called a gear blank.

Two principal methods of gear manufacturing include

Gear forming, and Gear generation.

Each method includes a number of

machining processes, the major of them included in this section.

Gear forming

In gear form cutting, the cutting

edge of the cutting tool has a shape identical with the shape of the space

between the gear teeth.

Two

machining operations, milling and broaching can be employed to form cut gear

teeth

Gear milling

In form milling, the cutter

called a form cutter travels axially along the length of the gear tooth at the

appropriate depth to produce the gear tooth. After each tooth is cut, the

cutter is withdrawn, the gear blank is rotated (indexed), and the cutter

proceeds to cut another tooth. The process continues until all teeth are cut.

Each cutter is designed to cut a

range of tooth numbers. The precision of the form-cut tooth profile depends on

the accuracy of the cutter and the machine and its stiffness. In form milling,

indexing of the gear blank is required to cut all the teeth. Indexing is the

process of evenly dividing the circumference of a gear blank into equally spaced

divisions. The index head of the indexing fixture is used for this purpose.

The index

fixture consists of an index head (also dividing head, gear cutting attachment)

and footstock, which is similar to the tailstock of a lathe. The index head and

footstock attach to the worktable of the milling machine. An index plate

containing graduations is used to control the rotation of the index head

spindle. Gear blanks are held between centers by the index head spindle and

footstock. Workpieces may also be held in a chuck mounted to the index head

spindle or may be fitted directly into the taper spindle recess of some

indexing fixtures.

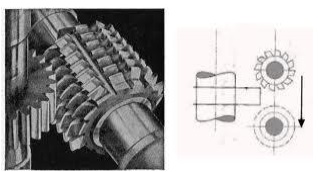

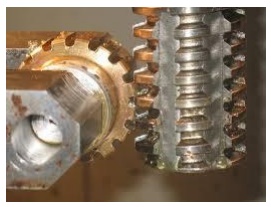

Gear

hobbing

Gear hobbing is a machining

process in which gear teeth are progressively generated by a series of cuts

with a helical cutting tool (hob). All motions in hobbing are rotary, and the

hob and gear blank rotate continuously as in two gears meshing until all teeth

are cut when bobbing a spur gear, the angle between the hob and gear blank axes

is 90° minus the lead angle at the hob threads. For helical gears, the hob is

set so that the helix angle of the hob is parallel with the tooth direction of

the gear being cut. Additional movement along the tooth length is necessary in

order to cut the whole tooth length: The action of the hobbing machine (also

gear hobber) is shown in the figures. The cutting of a gear by means of a hob

is a continuous operation. The hob and the gear blank are connected by a proper

gearing so that they rotate in mesh. To start cutting a gear, the rotating hob

is fed inward until the proper setting for tooth depth is achieved, then

cutting continues until the entire gear is finished.

The gear hob is a formed tooth

milling cutter with helical teeth arranged like the thread on a screw. These

teeth are fluted to produce the required cutting edges.

Related Topics