Chapter: Mechanical : Mechatronics : Mechatronics, Sensors And Transducers

Selection of Displacement, Position & Proximity Sensor

SELECTION OF DISPLACEMENT, POSITION &

PROXIMITY SENSOR:

Size of

the displacement (mm)

Displacement

type (Linear or angular)

Resolution

required

Accuracy

Required

Material

of the object

Cost

DISPLACEMENT

SENSORS

Displacement

sensors are con tact type sensor

Types of Displacement sensors:

Potentiometer

Strain

gauge

Capacitive

sensors

Linear

variable differential tr ansformer

POTENTIOMETER

PRINCIPLE:

It works

on variable resistance transduction principle

Linear or Rotary potentiometer is a variable

resistance displacement tran sducer which uses the variable resistance

transduction prin ciple in which the displacement or rotation isco

nverted into a potential differencedue to the movement ofsli

ding contact over a resistiveelement

CONSTRUCTION

& WORKING:

A

resistor with three terminals.

Two end

terminal & one mid dle terminal (wiper)

Two end

terminal are connected to external input voltage

One

middle and one end term inal as output voltage

The

slider determines the ma gnitude of the potential difference developed

Characteristics:

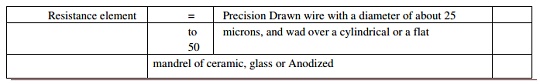

Resistance element = Precision Drawn wire with a diameter o f

about 25

to microns, and wad over a cylindrical or a

flat

50

mandrel of

ceramic, glass or Anodized

Aluminium. 2 mm to 500 mm in case of linear pot.

= For high resolution, w ire is made by using ceramic (cermet)

or conductive plastic

film d ue to

low noise levels.

Wipers (Sliders) = Tempered phosphor bronze, beryllium copper

or other precious alloys.

Wire Material = Strong, ductile and protected from surfa ce

corrosion by enamelling or oxidation.

Materials &e alloys

of copper nickel, Nickel chromium, and silver palladium.

= Resistivity of wire

ranges from 0.4 µΩm to 13 µΩm

Resistance range = 20Ω to 200KΩ and for plastic 500Ω to 80KΩ

Accuracy = Higher

temperature coefficient of

resistance than the

wire and so temperature changes have a greater effect Accuracy.

STRAIN

GAUGE:

Strain gauges

are passive type

resistance sensor whose

electrical resistance change

when it is

stretched or compressed (mechanically strained) under the

application of force.

The

electrical resistance is changed due to the change in length (increases) and

cross sectional area

(decreases) of the strain gauge.

This

change in resistance is then usually converted into voltage by connecting one,

two or four

similar gauges as an arm of a Wheatstone bridge (known as

Strain Gauge Bridge) and applying excitation to

the bridge. The bridge output voltage is then a measure of

strain, sensed by each strain gauge.

Unbonded Type Strain Gauges:

In unbonded type, fine wire filaments (resistance wires) are

stretched around rigid and electrically insulated pins on two frames.

One frame

is fixed and the other is movable.

The

frames are held close with a spring loaded mechanism.

Due to

the relative motion between two frames, the resistance wires are strained.

This strain is then can be detected through measurement of the

change in electrical resistance since they are not cemented with the surfaces,

they can be detached and reused.

Bonded Type Strain Gauges:

Bonded type strain gauges consists of resistance

elements arranged in the form of a grid of fine wire, which is cemented to a

thin paper sheet or very thin Bakelite sheet, and covered with a protective

sheet of paper or thin Bakelite.

The paper sheet is then bonded to the surface to be strained.

The gauges have a bonding material which acts an adhesive material during

bonding process of a surface with the gauge element.

Classification of Bonded Type Strain Gauges:

Fine wire

gauges

Metal

foil gauges

Semiconductor

filament type

Fine Wire Gauges:

Wire of 3

to 25 microns diameter is arranged in the form of grid consisting of parallel

loops

Metal Foil Gauges:

A thin foil of metal, deposited as a grid pattern onto a

plastic backing material using polyimide

Foil pattern is terminated at both ends with large metallic

pads Entire gauge size 5- 15mm

Adhesive directly

bonded to the gauge usually epoxy

Semiconductor Filament Type:

The

gauges are produced in wafers from silicon or germanium crystals

Special

impurities such as boron is added

It is

mounted on an epoxy resin backing with copper on nickel leads

Filament

about 0.05mm thick 0.25mm wide and 1.25 to 12mm length

CAPACITIVE SENSORS:

It is

used for measuring, displacement, velocity, force etc..

Principle:

It is passive type sensors in

which equal and opposite charges are generated on the plates due

to voltage applied across the plate which is separated by

dielectric material.

Formula:

By Changing the Distance between Two Plates:

The

displacement is measured due to the change in capacitance

By

Varying the Area of Overlap:

The

displacement causes the area of overlap to vary

The capacitance is directly proportional to the area of the

plates and varies linearly with changes in the displacement between the plates

By Varying the Dielectric Constant:

The change in capacitance can be measured due to change in

dielectric constant as a result of displacement.

When the dielectric material is moved due to the displacement,

the material causes the dielectric constant to vary in the region where the two

electrodes are separated that results in a charge in capacitance.

Push Pull Sensor:

Push pull displacement sensor is used to overcome the

non-linearity error.

The sensor consists of three plates with the upper pair

forming one capacitor and the lower pair forming another capacitor.

The

displacement moves central plate between the two other plates.

If the

central plate moves downwards.

The plate

separation of the upper capacitor increases and the separation of the lower one

decreases.

LINEAR VARIABLE DIFFERENTIAL TRANSFORMER:

It

consists of three symmetrically spaced coils.

The

centre coil is primary coil and other two are secondary coil

Secondary coils are connected in series opposition and equally

positioned with respect to primary coil

The

output voltage is proportional to the displacement of the core from null

position

PROXIMITY SENSORS

Proximity

sensors are non – contact type sensor.

Types of Proximity Sensor:

Eddy

current proximity sensor

Inductive

proximity sensor

Pneumatic

proximity sensor

Proximity

switches

EDDY CURRENT PROXIMITY SENSOR:

PRINCIPLE:

When a

coil is supplied with alternating current, an alternating magnetic

field is produced which

induces an EMF on it. If

there is a metal near to this alternating magnetic field, on EMF

is induced in it.

The EMF cause current to flow. This current flow

is eddy current.

CONSTRUCTION & WORKING:

It has

two identical coils.

One reference coil & another sensing coil which senses the

magnetic current in the object. Eddy current start to flow due to AC(conducting

object) close to sensor

Eddy current produce a magnetic field to oppose the magnetic

field generated by sensing coil. Due to this opposition reduction flux is

created. To detect 0.001mm

INDUCTIVE PROXIMITY SENSORS:

It

consists of coil wound round a core.

Metal is

close to coil Inductance changes occurs.

It is

suitable for ferrous metals

PNEUMATIC PROXIMITY SWITCHES:

It is

suitable for sensing non conducting materials

Air is

allowed to escape from the front side of the sensor.

When

there is no object air escapes freely.

When there

is an object, the escaping air is blocked and return backed to system.

It is

used to measure the range 3mm to 12mm

PROXIMITY SWITCHES:

It is

used in robotics for sensing elements

It is also used in NC machines, material handling

systems and assembly lines. Micro switch

Reed

switch

Photo sensitive switch Mechanical switch

Micro Switch:

It is limit switch operated by levers, rollers & cams

It is switch which requires physical contact and small force

to close the contacts. Example a belt conveyor.

Reed Switch:

It is a non – contact proximity switch that consists of two

magnetic switch contacts enclosed in a glass tube fined with

an inert gas.

When magnet is closed switch is operated. Used for high speed

applications.

Photo Sensitive Devices:

It is

used to sense opaque object.

Photo

detector receives a beam of light produced by the LED.

Object is

passed the beam gets broken or reflected when is detected.

Related Topics