Chapter: civil : Applied Hydraulic Engineering: Pumps

Reciprocating Pumps

Reciprocating Pumps

Introduction

There are two main types of pumps namely the dynamic and

positive displacement pumps. Dynamic pumps consist of centrifugal, axial and

mixed flow pumps. In these cases pressure is developed by the dynamic action of

the impeller on the fluid.

Momentum

is imparted to the fluid by dynamic action. This type was discussed in the

previous chapter. Positive displacement pumps consist of reciprocating and

rotary types. These types of pumps are discussed in this chapter. In these

types a certain volume of fluid is taken in an enclosed volume and then it is

forced out against pressure to the required application.

1 Comparison

Dynamic pumps

1. Simple in

construction.

2. Can

operate at high speed and hence compact.

3. Suitable

for large volumes of discharge at moderate pressures in a single stage.

4. Lower

maintenance requirements.

5. Delivery

is smooth and continuous.

Positive displacement

pumps

1. More

complex, consists of several moving parts.

2. Speed is

limited by the higher inertia of the moving parts and the fluid.

3. Suitable

for fairly low volumes of flow at high pressures.

4. Higher

maintenance cost.

5. Fluctuating

flow.

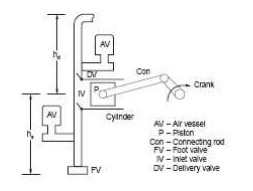

2.Description And Working

The main

components are:

1. Cylinder

with suitable valves at inlet and delivery.

2. Plunger

or piston with piston rings.

3. Connecting

rod and crank mechanism.

4. Suction

pipe with one way valve.

5. Delivery

pipe.

6. Supporting

frame.

7. Air vessels to reduce flow fluctuation and reduction of

acceleration head and friction head.

A

diagrammatic sketch is shown in Fig

The action is similar to that of reciprocating engines. As the

crank moves outwards, the piston moves out creating suction in the cylinder.

Due to the suction water/fluid is drawn into the cylinder through the inlet

valve. The delivery valve will be closed during this outward stroke.

During the return stroke as the fluid is incompressible

pressure will developed immediately which opens the delivery valve and closes

the inlet valve. During the return stroke fluid will be pushed out of the

cylinder against the delivery side pressure. The functions of the air vessels

will be discussed in a later section. The volume delivered per stroke will be

the product of the piston area and the stroke length.

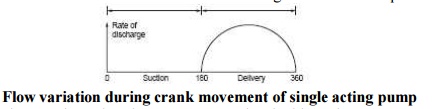

In a single acting type of pump there will be only one

delivery stroke per revolution. Suction takes place during half revolution and

delivery takes place during the other half. As the piston speed is not uniform

(crank speed is uniform) the discharge will vary with the position of the

crank. The discharge variation is shown in figure.

In a

single acting pump the flow will be fluctuating because of this operation.

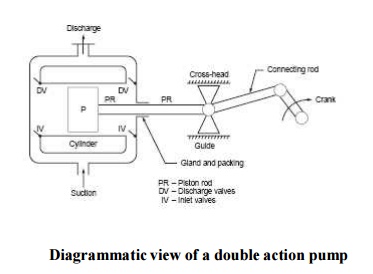

Fluctuation can be reduced to some extent by double acting

pump or multicylinder pump. The diagrammatic sketch of a double acting pump is

shown in figure In this case the piston cannot be connected directly with the

connecting rod.

A gland and packing and piston rod and cross- head and guide

are additional components. There will be nearly double the discharge per

revolution as compared to single acting pump.When one side of the piston is

under suction the other side will be delivering the fluid under pressure. As

can be noted, the construction is more complex

.

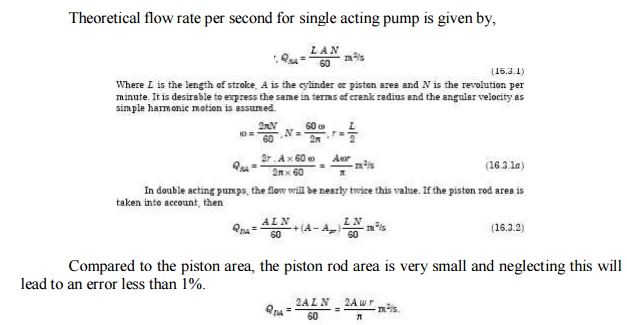

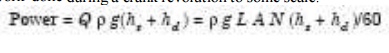

3.Flow Rate and Power

Theoretical

flow rate per second for single acting pump is given by,

Compared to the piston area, the piston rod area is very small

and neglecting this will lead to an error less than 1%.

4.Slip

There can

be leakage along the valves, piston rings, gland and packing which will reduce

the discharge to some extent. This is accounted for by the term slip.

Percentage

o Slip = Qa -Qn / Qa x 100

Where Qth is the

theoretical discharge given by equation and Qac is the measured

discharge. If actual discharge is greater than theoretical discharge negative

value is found

this negative

value is called negative slip.

5.Coefficient

of discharge

It has

been found in some cases that Qac > Qth, due to operating

conditions. In this case the slip is called negative slip. When the delivery

pipe is short or the delivery head is small and the accelerating head in the

suction side is high, the delivery valve is found to open before the end of

suction stroke and the water passes directly into the delivery pipe. Such a

situation leads to negative slip.

Theoretical power = mg(hs + hd ) W

where m is given by Q × ?.

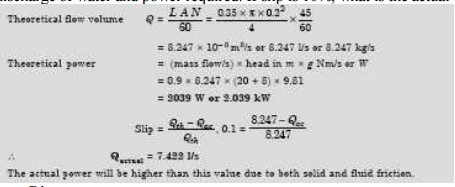

Problem.1

A

single acting reciprocating pump has a bore of 200 mm and a stroke of 350 mm

and runs at 45 rpm. The suction head is 8 m and the delivery head is 20 m.

Determine the theoretical discharge of water and power required. If slip is

10%, what is the actual flow rate ?

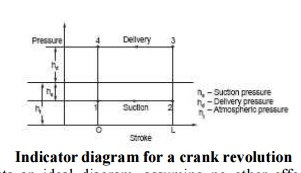

6.Indicator Diagram

The

pressure variation in the cylinder during a cycle consisting of one revolution

of the crank. When represented in a diagram is termed as indicator diagram. The

same is shown in figure.

Figure represents an ideal diagram, assuming no other effects

are involved except the suction and delivery pressures. Modifications due to

other effects will be discussed later in the section. Point 1 represents the

condition as the piston has just started moving during the suction stroke.

1-2

represents the suction stroke and the pressure in the cylinder is the suction

pressure below the atmospheric pressure. The point 3 represents the condition

just as the piston has started moving

when the pressure increases to the delivery

pressure. Along 3-4 representing

the delivery stroke the pressure

remains constant. The

area enclosed represents the work done during a crank

revolution to some scale.

7.Acceleration Head

The piston in the reciprocating pump has to move from rest

when it starts the suction stroke. Hence it has to accelerate. The water in the

suction pipe which is also not flowing at this point has to be accelerated.

Such acceleration results in a force which when divided by area results as

pressure.

When the

piston passes the mid point, the velocity gets reduced and so there is

retardation of the piston together with the water in the cylinder and the pipe.

This again results in a pressure. These pressures are called acceleration

pressure and is denoted as head of fluid (h = P/?g) for

convenience.

Referring

to the figure shown below the following equations are written.

This is

the acceleration in the cylinder of area A. The acceleration in the pipe

of area a is=A/a w2rcosot.This head is imposed on the piston in addition to the

static head at that condition.This results in the modification of the indicator

diagram as shown in figure.

The effect of acceleration

head are:

No change in the work done. pressure at 1?is around

2.5 m of head of water (absolute). Which is directly related to speed, the

speed of operation of reciprocating pumps is limited. Later it will be shown

than the installation of an air vessel alleviates this problem to some extent.

8.Work done by the Pump

For

single acting

W=

?gALN(hs+hd+0.67hfs+0.67hfd)/60

For

Double acting

W=2?gALN(hs+hd+0.67hfs+0.67hfd)/60

Where

hfs, hfd =loss of head due to acceleration in the suction and delivery Pipe.

Related Topics