Chapter: civil : Applied Hydraulic Engineering: Pumps

Pumps: Air Vessels

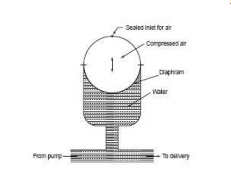

Air Vessels

Air

vessel is a strong closed vessel as shown in figure. The top half contains

compressed air and the lower portion contains water or the fluid being pumped.

Air and water are separated by a flexible diaphragm which can move up

or down depending on the difference

in pressure between the fluids. The

air charged at

near total delivery pressure/suction pressure from the

top and sealed. The air vessel is connected to the pipe lines very near the

pump, at nearly the pump level. On the delivery side, when at the beginning and

up to the middle of the delivery stroke the head equals hs + hf + ha , higher

than the static and friction heads. At this time part of the water from pump

will flow into the air vessel and the remaining will flow through the delivery

pipe. This will increase the compressed air pressure. At the middle stroke

position the head will be sufficient to just cause flow. The whole of the flow

from pump will flow to the delivery pipe. At the second half of the stroke the

head will be equal to hs + hf - ha. At the position the head will be not

sufficient to cause flow. The compressed air pressure will act on the water and

water charged earlier into the air vessel will now flow out. Similar situation

prevails on the suction side. At the start and up to the middle of the suction

stroke the head at the pump is higher than static suction head by the amount of

acceleration head. The flow will be more and part will flow into the air

vessel. The second half of the stroke water will flow out of the air vessel.

In this

process the velocity of water in the delivery pipe beyond the air vessel is

uniform, and lower than the maximum velocity if air vessel is not fitted.

Similar situation prevails in the suction side also. The effect is not only to

give uniform flow but reduce the friction head to a considerable extent saving

work. Without air vessel the friction head increases, reaches a maximum value

at the mid stroke and then decreases to zero. With air vessel the friction head

is lower and is constant throughout the stroke. This is due to the constant

velocity in the pipe.

The advantages of

installing air vessels are:

(i)

The flow fluctuation is reduced and a uniform

flow is obtained.

(ii)

The friction work is reduced.

(iii)

The acceleration head is reduced considerably.

(iv)

Enables the use of higher speeds.

Related Topics