Chapter: Civil : Railway Airport Harbour Engineering : Railway Engineering : Railway Tunnelling

Railway Tunnelling: Ventilation of Tunnels

Ventilation of Tunnels

A tunnel should be properly

ventilated during as well as after the construction for the reasons given

below.

(a) To

provide fresh air to the workers during construction.

(b) To remove

the dust created by drilling, blasting, and other tunnelling operations.

(c) To remove

dynamite fumes and other objectionable gases produced by the

use of

dynamites and explosives.

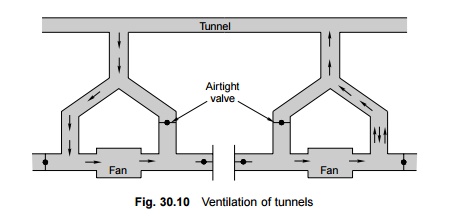

The methods listed below are

normally adopted for the ventilation of a tunnel. These are illustrated in Fig.

30.10.

Natural method of ventilation This is

achieved by drilling a drift through the tunnel from portal to portal.

In most cases natural ventilation is not sufficient and artificial ventilation

is still required.

Mechanical ventilation by blow-in

method In the blow-in method, fresh air is forced through a

pipe or fabric duct by the means of a fan and supplied near the washing face

(or the drilling face; the drilling operation requires the washing of bore

holes too). This method has the advantage that a fresh air supply is guaranteed

where it is required the most. The disadvantage is that the foul air and fumes

have to travel a long distance before they can exit the tunnel and in the

process it is possible that the incoming fresh air will absorb some dust and

smoke particles.

Mechanical ventilation by exhaust

method In the exhaust or blow-out method, foul air and fumes

are pulled out through a pipe and is expelled by a fan. This sets up an air

current that facilitates the entrance of fresh air into the tunnel. This method

has the advantage that foul air is kept out of the washing face. The disadvantage,

however, is that fresh air has to travel a long distance before it can reach

the washing face during which period it may absorb some heat and moisture.

Combination of blow-in and

blow-out methods By combining the blow-in and blow-out

methods using a blower and an exhaust system, respectively, a tunnel can be

provided with the best ventilation. After blasting the ground, the exhaust

system is used to remove the smoke and dust. After some time, fresh air is

blown in through the ducts and the rotation of the fans is reversed to reverse

the flow of air.

Related Topics