Chapter: Environmental Engineering : Conveyance System

Pipes And Conduits For Water- Pipe Materials

PIPES

AND CONDUITS FOR WATER- PIPE MATERIALS

The earliest known evidence of drain tile being used

for plumbing was found in Mesopotamia and is estimated to have been made around

3000 BC. The tiles were made from clay mixed with short lengths of straw. Both

brass and copper pipes have been found in Egypt believed to have been made

close to 2500 BC. The Romans made extensive use of lead pipe by joining sheets

of lead into piping to carry their water supply and waste. During the Dark Ages

following the fall of the Roman Empire, plumbing development virtually ceased

for centuries except for isolated cases of plumbing installed in palaces and

castles. In the 13th century, blacksmiths formed sheets of iron and lap welded

the seam to create iron pipe. Though it is unclear as to when galvanized iron

pipe was first used, a French chemist named Melouin is credited with developing

the process in 1742. The earliest known use for cast iron pipe is for the water

supply to a fountain in Langensalza,Germany, built around 1560. In 1819 the

first cast iron pipe constructed in the US, was manufactured in Weymouth, New

Jersey. Before that time, cast iron pipe and fittings had to be imported from

Europe. It was not until the 1960's that the hubless cast iron pipe was brought

to the U.S. from Europe by way of Canada. During the early 1900's, heavy-walled

copper joined with threaded fittings was in use, but limited to public

buildings because of its' high cost. However, during the 1930's light-gauge

Copper tube and fittings were developed which made copper economically feasible

and increased it's popularity. Polyvinyl Chloride(PVC) was produced

experimentally in the 19th century but did not become practical to manufacture

until 1926, when Waldo Semon of BF Goodrich Co. developed a method to

plasticize PVC, making it easier to process. PVC pipe began to be manufactured

in the 1940's and was in wide use during the DWV reconstruction of Germany and

Japan following WWII. In the 1950's, plastics manufacturers in Western Europe

and Japan began producing acrylonitrile butadiene styrene(ABS) pipe. The

methods for producing cross-linked polyethylene(PEX) was also developed in the

1950's. Plastic supply pipes have become increasingly common, with a variety of

materials and fittings employed, however plastic water pipes do not keep water

as clean as copper and brass piping does. Copper pipe plumbing is

bacteriostatic. This means that bacteria can't grow in the copper pipes.

Plumbing codes define which materials may be used, and all materials must be

proven by ASTM, UL, and/or NFPA testing.

Steel

Galvanized steel potable water supply and

distribution pipes are commonly found with nominal diameters from 3/8" to

2". It is rarely used today for new construction residential plumbing.

Steel pipe has National Pipe Thread (NPT) standard tapered male threads, which

connect with female tapered threads on elbows, tees, couplers, valves, and

other fittings. Galvanized steel (often known simply as "galv" or

"iron" in the plumbing trade) is relatively expensive, difficult to

work with due to weight and requirement of a pipe threader. It remains in

common use for repair of existing "galv" systems and to satisfy

building code non-combustibility requirements typically found in hotels,

apartment buildings and other commercial applications. It is also extremely

durable. Black lacquered steel pipe is the most widely used pipe material for

fire sprinklers and natural gas.

Most single family homes' systems typically won't

require supply piping larger than 3/4". In addition to expense, another

downside is it suffers from a tendency to obstruction due to internal rusting

and mineral deposits forming on the inside of the pipe over time after the

internal galvanizing zinc coating has degraded. In potable water distribution

service, galvanized steel pipe has a service life of about 30 to 50 years,

although it is not uncommon for it to be less in geographic areas with

corrosive water contaminants.

Lead

leaching

Generally, copper tubes are soldered directly into

copper or brass fittings, although compression, crimp, or flare fittings are

also used. Formerly, concerns with copper supply tubes included the lead used

in the solder at joints (50% tin and 50% lead). Some studies have shown

significant "leaching" of the lead into the potable water stream,

particularly after long periods of low usage, followed by peak demand periods.

In hard water applications, shortly after installation, the interior of the

pipes will be coated with the deposited minerals that had been dissolved in the

water, and therefore the vast majority of exposed lead is prevented from

entering the potable water. Building codes now require lead-free solder.

Building Codes throughout the U.S. require the use of virtually

"lead-free" (<.2% lead) solder or filler metals in plumbing

fittings and appliances as well.

Corrosion

Copper water tubes are

susceptible to: cold water pitting caused by contamination of the pipe interior

typically with soldering flux; erosion corrosion caused by high speed or

turbulent flow; and stray current corrosion, caused by poor electrical wiring

technique, such as improper grounding and bonding.

Pin

holes due to poor plumbing electrical grounding and/or bonding

Pin-hole leaks can occur anytime copper piping is

improperly grounded and/or bonded; nonmetal piping, such as Pex or PVC, does

not suffer from this problem. The phenomenon is known technically as stray

current corrosion or electrolytic pitting. Pin-holing due to poor

grounding or poor bonding occurs typically in homes where the original plumbing

has been modified; homeowners may find a new plastic water filtration device or

plastic repair union has interrupted the water pipe's electrical continuity to

ground when they start seeing pinhole water leaks after a recent install.

Damage occurs rapidly, usually being seen about six months after the ground

interruption. Correctly installed plumbing appliances will have a copper

bonding jumper cable connecting the interrupted pipe sections. Pinhole leaks

from stray current corrosion can result in thousands of dollars in plumbing

bills, and sometimes necessitating the replacement of the entire affected line.

The cause is an electrical problem, not a plumbing problem; once the plumbing

damage is repaired, an electrician should be consulted to evaluate the

grounding and bonding of the entire plumbing system.

The

difference between a ground and a bond is subtle. See Ground

(electricity), find the heading

AC

power wiring installations for a complete description.

Stray current corrosion occurs because: 1) the

piping system is connected accidentally or intentionally to a DC voltage

source; 2) the piping does not have metal-to-metal electrical continuity; 3) if

the voltage source is AC, one or more naturally occurring minerals coating the

pipe interior act as a rectifier, converting AC current to DC . The DC voltage

forces the water within the piping to act as an electrical conductor (an

electrolyte). Electric current leaves the copper pipe, moves though the water

across the nonconductive section (the plastic filter housing in the example

above), and reenters the pipe on the opposite side. Pitting occurs at the

electrically negative side (the cathode), which may be upstream or downstream

with respect to the water flow direction. Pitting occurs because the electrical

voltage ionizes the pipe's interior copper metal, which reacts chemically with

dissolved minerals in the water creating copper salts; these copper salts are

soluble in water and wash away. Pits eventually grow and consolidate to form

pin holes. Where there is one, there are almost certainly more. A complete

discussion of stray current corrosion can be found in chapter 11, section

11.4.3, of Handbook of Corrosion Engineering, by Pierre Roberge.

Detecting and eliminating poor bonding is relatively

straightforward. Detection is accomplished by use of a simple voltmeter set to

DC with the leads placed in various places in the plumbing. Typically, a probe

on a hot pipe and a probe on a cold pipe will tell you if there is improper

grounding. Anything beyond a few millivolts is important, potentials of 200 mV

are common. A missing bond will show up best in the area of the gap, as

potential disperses as the water runs. Since the missing bond is usually seen

near the water source, as filtration and treatment equipment are added, pinhole

leaks can occur anywhere downstream. It is usually the cold water pipe, as this

is the one that gets the treatment devices.

Correcting the problem is a simple matter of either

purchasing a copper bonding jumper kit, composed of copper cable at least #6 AWG

in diameter and two bronze ground clamps for affixing it the plumbing. See NFPA

70, the U.S. National Electrical Code Handbook (NEC), section on bonding and

ground for details on selecting the correct bonding conductor wire size.

A

similar bonding jumper wire can also be seen crossing gas meters, but for a

different reason.

Note, if homeowners

are experiencing shocks or sparks from plumbing fixtures or pipes, it is more

than a missing bond, it is likely a live electrical wire is bridging to the

plumbing and the plumbing system is not grounded. This is an electrical shock

hazard and potential fire danger; consult an electrician immediately!

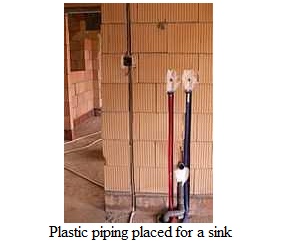

Plastics

Plastic pipe is in wide use for domestic water

supply and drainage, waste, and vent (DWV) pipe. For example, polyvinyl

chloride (PVC), chlorinated polyvinyl chloride (CPVC), polypropylene (PP),

polybutylene (PB), and polyethylene (PE) may be allowed by code for certain

uses. Some examples of plastics in water supply systems are:

· PVC/CPVC

- rigid plastic pipes similar to PVC drain pipes but with thicker walls to deal

with municipal water pressure, introduced around 1970. PVC should be used for

cold water only, or venting. CPVC can be used for hot and cold potable water

supply. Connections are made with primers and solvent cements as required by

code.

· PP

- The material is used primarily in housewares, food packaging, and clinical

equipment, but since the early 1970s has seen increasing use worldwide for both

domestic hot and cold water. PP pipes are heat fused, preventing the use of

glues, solvents, or mechanical fittings. PP pipe is often used in green

building projects.

PBT - flexible (usually

gray or black) plastic pipe which is attached to barbed fittings and secured in

place with a copper crimp ring. The primary manufacturer of PBT tubing and

fittings was driven into bankruptcy by a class-action lawsuit over failures of

this system. However, PB and PBT tubing has returned to the market and codes,

typically first for 'exposed locations' such as risers.

· PEX

- cross linked polyethylene system with mechanically joined fittings employing

barbs and crimped steel or copper fittings.

· Polytanks

- plastic polyethylene cisterns, underground water tanks, above ground water

tanks, are made of linear polyethylene suitable as a potable water storage

tank, provided in white, black or green, approved by NSF and made of FDA

approved materials.

· Aqua

- known as PEX-Al-PEX, for its PEX/aluminum sandwich - aluminum pipe sandwiched

between layers of PEX and connected with brass compression fittings. In 2005, a

large number of their fittings were recalled.

Fittings

and valves

Potable water supply systems require not only pipe,

but also many fittings and valves which add considerably to their functionality

as well as cost. The Piping and plumbing fittings and Valves articles discuss

them further.

Related Topics