Chapter: Flexible Alternating Current Transmission System : Introduction

Overview of FACTS Devices

OVERVIEW OF FACTS DEVICES

1. SVC – Static Var Compensator

Ø A SVC is

an electrical device for providing fast acting reactive power on high-voltage

electricity transmission networks.

Ø SVCs are

part of the FACTS device family and regulating voltage and stabilizing the

system.

Ø

Unlike a synchronous condenser which is a rotating

electrical machine a SVC has no significant moving parts and prior to the invention of the

SVC power factor compensation was

the preserve of large rotating machines such as synchronous condensers or

switched capacitor banks.

Ø The SVC

is an automated impedance matching device designed to bring the system closer

to unity power factor.

Ø SVCs are

used in two main situations:

o Connected to the power system, to regulate the

transmission voltage.

o

Connected near large industrial loads, to improve

power quality.

Ø In

transmission applications the SVC is used to regulate the grid voltage.

Ø If the

power system’s reactive load is capacitive (leading) the SVC will use thyristor

controlled reactors to consume vars from the system lowering the system

voltage.

Ø Under

inductive (lagging)conditions the capacitor banks are automatically switched on

thus providing a higher system voltage and by connecting the

thyristor-controlled reactor which is continuously variable along with a

capacitor bank step and the net result is continuously-variable leading or

lagging power.

Ø In

industrial applications SVCs are typically placed near high and rapidly varying

loads such as arc furnaces where they can smooth flicker voltage.

Description:

Typically

an SVC comprises one or more banks of fixed or switched shunt capacitors or

reactors of which atleast one bank is switched by thyristors.

The elements which may be used to make an SVC typically include:

Thyristor Controlled Reactor (TCR) where the reactor may be air or iron cored.

Thyristor

Switched Capacitor (TSC).

Harmonic filter(s).

Mechanically switched capacitors or reactors.

Connection:

Ø Generally

SVC is not done at line voltage; a bank of transformers steps the transmission

voltage down to a much lower level.

Ø This

reduces the size and number of components needed in the SVC although the

conductors must be very large to handle high currents associated with the lower

voltage.

Ø In some

SVC for industrial applications such as electric arc furnaces where there may

be an existing medium-voltage bus bar present the SVC may be directly connected

in order to save the cost of the transformer.

Ø The

dynamic nature of the SVC lies in the use of thyristors connected in series and

inverse-parallel forming “thyristor valves” and the disc-shaped semiconductors

usually several inches in diameter are usually located indoors in a “valve

house”.

Advantages:

Ø Near

instantaneous response to changes in the system voltage. For this reason they

are often operated at close to their zero-point in order to maximize the

reactive power correction they can rapidly provide when required.

Ø In

general, cheaper, higher-capacity, faster and more reliable than dynamic

compensation schemes such as synchronous condensers.

2. Thyristor Controlled Series

Capacitor (TCSC)

Ø TCSC is a

power electronic based system and Thyristor Switched Capacitor is connected in

series with a bidirectional thyristor valve.

Ø The TCSC

can control power flow, mitigate sub-synchronous resonance, improve transient

stability, damp out power system oscillations resulting increase of power

transfer capability.

Ø A single

diagram of TCSC shows two modules connected in series and there can be one or

more module depending on the requirement to reduce the costs and TCSC may be

used in conjunction with fixed series capacitors.

Ø Nowadays

TCSC is being included in some of the transmission systems and the basic

circuit of a TCSC in one of the phase is shown in the fig.controls the current

through the reactor.

Ø The

forward-looking thyristor has firing angle 900 – 1800 and

firing the thyristors at this time results in a current flow through the

inductor that is opposite to the capacitor current and in this loop current

increases the voltage across the capacitor.

Ø Further

the loop current increases as firing angle decreases from 1800.

Ø The

different compensation levels are obtained by varying the firing angle of the

reactor-circuit-thyristor.

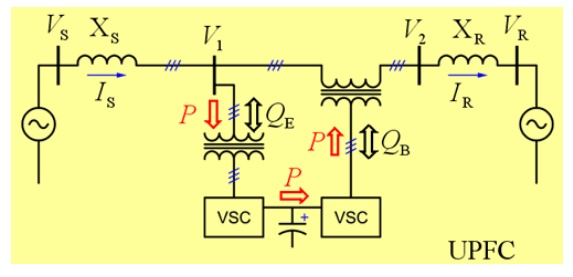

3. UNIFIED POWER FLOW CONTROLLER

(UPFC)

Ø The UPFC

is the most versatile member of FACTS family using power electronics to control

power flow on power grids.

Ø The UPFC

uses a combination of a shunt controller (STATCOM) and a series controller

(SSSC) interconnected through a common DC bus.

P = (V2V3 sinᵟ)/X and Q

= (V2(V2 – V3 cosᵟ))/X

Ø This

FACTS topology provides much more flexibility than the SSSC for controlling the

line active and reactive power because active power can now be transferred from

the shunt converter to the series converter through the DC bus.

4. INTEGRAL POWER FLOW CONTROLLER

(IPFC)

Ø In other

FACTS controllers there are two or more VSCs coupled together via a common DC

bus which increases not only the controllability but also the complexity.

Ø For UPFC

the connection between the shunt VSC and series VSC allows active power

exchange of the two VSCs so the series VSC can control both the line active and

reactive power flow.

Ø The shunt

VSC regulates the bus voltage and satisfies the balance of power circulation

through the DC capacitor.

Ø For IPFC

two series VSCs connect to each other at the DC bus so one of them (assumed as

the Master VSC) can control both line active and reactive power and the other

one (assumed as Slave VSC) can only regulate line active power supporting sufficient

active power to the Master VSC through the DC tie.

Related Topics