Chapter: Mechanical : Unconventional machining process : Mechanical Energy Based Processes

Mechanical Energy Based Processes

MECHANICAL

ENERGY BASED PROCESSES

MECHANICAL

PROCESSES

•

Abrasive

Jet Machining (AJM)

•

Abrasive

Water Jet Machining (AWJM)

•

Water

Jet Machining (WJM)

•

Ultrasonic

Machining (USM)

1

ABRASIVE JET MACHINING (AJM)

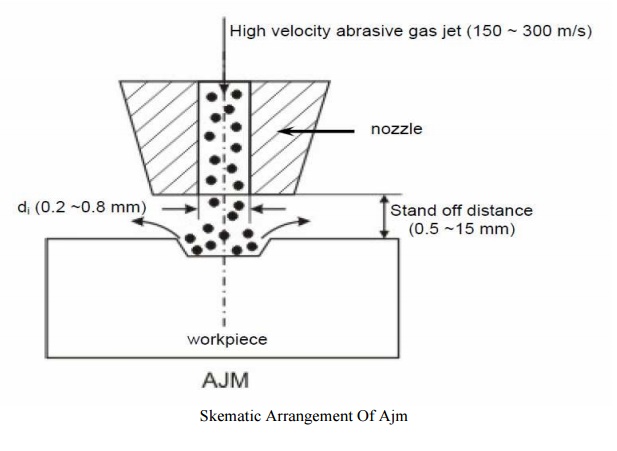

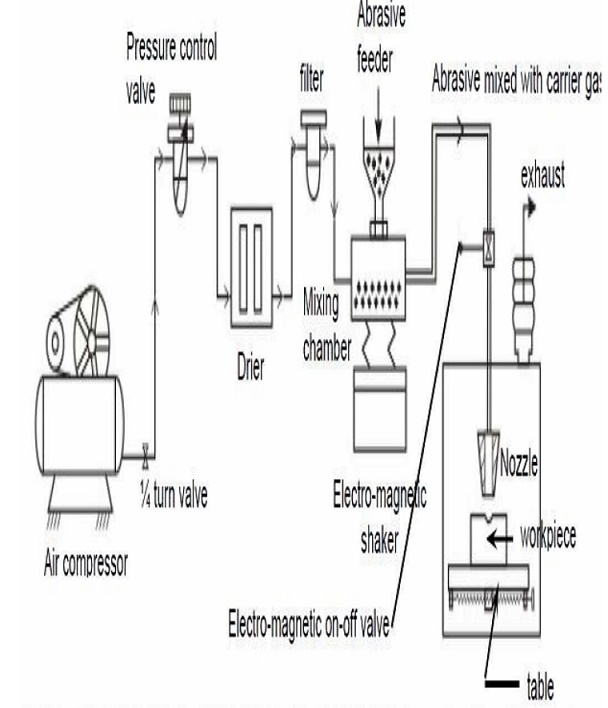

In

Abrasive Jet Machining (AJM), abrasive particles are made to impinge on the

work material at a high velocity. The high velocity abrasive particles remove

the material by micro-cutting action as well as brittle fracture of the work

material.

In AJM, generally, the abrasive

particles of around 50 μm grit size would impinge on the work material at

velocity of 200 m/s from a nozzle of I.D. of 0.5 mm with a standoff distance of

around 2 mm. The kinetic energy of the abrasive particles would be sufficient

to provide material removal due to brittle fracture of the work piece or even

micro cutting by the abrasives.

1. Process Parameters and Machining Characteristics

Abrasive: Material – Al2O3 / SiC /

glass beads

Shape – irregular / spherical

Size – 10 ~ 50 μm

Mass flow rate – 2 ~ 20 gm/min

Carrier gas: Composition – Air, CO2,

N2

Density – Air ~ 1.3 kg/m3

Velocity – 500 ~ 700 m/s Pressure –

2 ~ 10 bar

Flow rate – 5 ~ 30 lpm

Abrasive Jet : Velocity – 100 ~ 300

m/s

Mixing ratio – mass flow ratio of abrasive

to gas

Stand-off distance – 0.5 ~ 5 mm

Impingement

Angle – 60 ~ 90

Nozzle: Material – WC

Diameter – (Internal) 0.2 ~ 0.8 mm

Life – 10 ~ 300 hours

.2. Modeling of material removal

Material

removal in AJM takes place due to brittle fracture of the work material due to

impact of high velocity abrasive particles.

3. Modeling has been done with the following assumptions:

(i) Abrasives are spherical in shape and

rigid. The particles are characterized by the mean grit diameter

(ii) The kinetic energy of the abrasives

are fully utilized in removing material

(iii) Brittle materials are considered to

fail due to brittle fracture and the fracture volume is considered to be

hemispherical with diameter equal to choral length of the indentation

(iv) For ductile material, removal

volume is assumed to be equal to the indentation volume due to particulate

impact

2.

WATER JET MACHINING (WJM)

2.1. Introduction

Water

jet cutting can reduce the costs and speed up the processes by eliminating or

reducing expensive secondary machining process. Since no heat is applied on the

materials, cut edges are clean with minimal burr. Problems such as cracked edge

defects, crystallization, hardening, reduced wealdability and machinability are

reduced in this process.

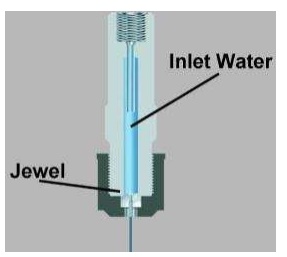

Water

jet technology uses the principle of pressurizing water to extremely high

pressures, and allowing the water to escape through a very small opening called

“orifice” or “jewel”. Water jet cutting uses the beam of water exiting the

orifice to cut soft materials. This method is not suitable for cutting hard

materials. The inlet water is typically pressurized between1300 – 4000 bars.

This high pressure is forced through a tiny hole in the je el, hich is

typically 0.18 to 0.4 mm in diameter. Picture of water jet chining process.

2.2. Applications

Water

jet cutting is mostly used to cut lower strength materials such as wood,

plastics and aluminium. When abrasives are added, (abrasive water jet cutting)

stronger materials such as steel and tool steel.

2.3. Advantages Of Water Jet Cutting

• There is no heat generated in

water jet cutting; which is especially useful for cutting tool steel and other

metals where excessive heat may change the properties of the material.

•

Unlike

machining or grinding, water jet cutting does not produce any dust or particles

that are harmful if inhaled.

•

Other

advantages are similar to abrasive water jet cutting

2.4. Disadvantages of water jet cutting

•

One

of the main disadvantages of water jet cutting is that a limited number of

materials can be cut economically.

•

Thick

parts cannot be cut by this process economically and accurately

•

Taper

is also a problem with water jet cutting in very thick materials. Taper is when

the jet exits the part at different angle than it enters the part, and cause

dimensional inaccuracy.

3. ABRASIVE WATER-JET MACHINING (AWJM)

3.1. Introduction

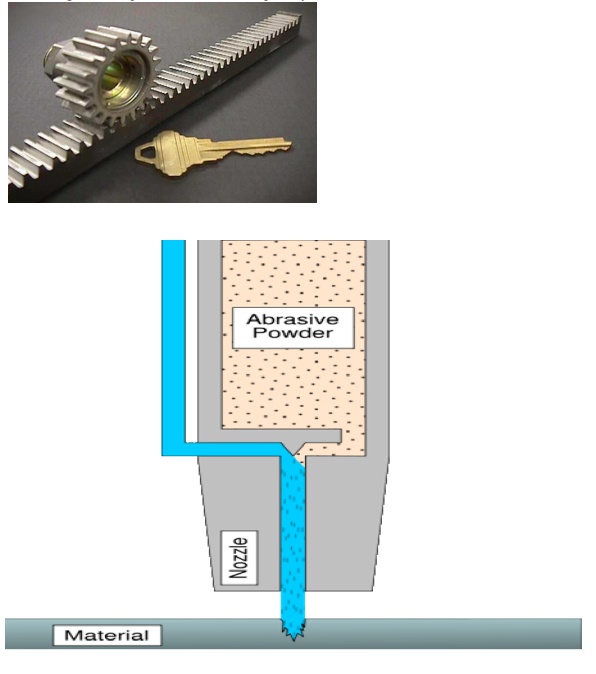

Abrasive

water jet cutting is an extended version of water jet cutting; in which the

water jet contains abrasive particles such as silicon carbide or aluminium

oxide in order to increase the material removal rate above that of water jet

machining. Almost a ny type of material ranging from hard brittle materials

such as ceramics, metals and glass to extremely soft materials such as foam and

rubbers can be cut by abrasive water jet cutting. The narrow cutting stream and

computer controlled movement enables this process to produce parts accurately

and efficiently. This machining process is especially ideal for cutting

materials that cannot be cut by laser or thermal cut. Metallic, non-metallic

and advanced composite materials of various thicknesses can be cut by this

process. This process is particularly suitable for heat sensitive materials

that cannot be machined by processes that produce heat while machining.

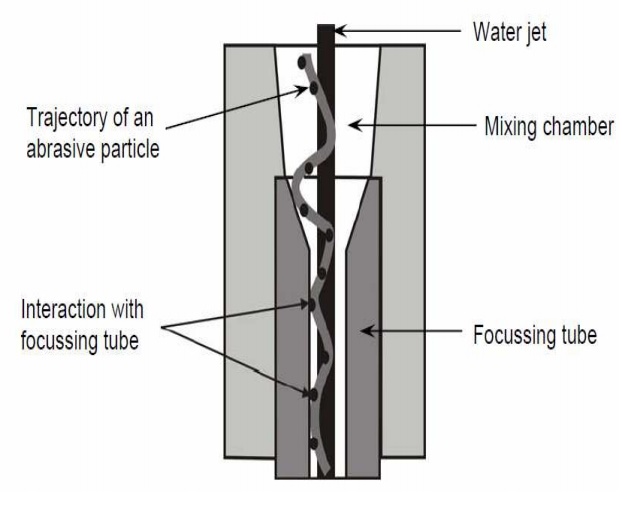

The schematic of abrasive water jet

cutting is shown in Figure 15 which is similar to water jet cutting apart from

some more features underneath the jewel; namely abrasive, guard and mixing

tube. In this process, high velocity water exiting the jewel creates a vacuum

which sucks abrasive from the abrasive line, which mixes with the water in the

mixing tube to form a high velocity beam of abrasives.

3.2.Applications

Abrasive water jet cutting is highly used in aerospace, automotive and electronics industries. In aerospace industries, parts such as titanium bodies for military aircrafts, engine components (aluminium, titanium, and heat resistant alloys), aluminium body parts and interior cabin parts are made using abrasive water jet cutting.

In

automotive industries, parts like interior trim (head liners, trunk liners, and

door panels) and fiber glass body components and bumpers are made by this

process. Similarly, in electronics industries, circuit boards and cable

stripping are made by abrasive water jet cutting.

.3.4.Advantages of abrasive water jet cutting

•

In

most of the cases, no secondary finishing required

•

No

cutter induced distortion

•

Low

cutting forces on work pieces

•

Limited

tooling requirements

•

Little

to no cutting burr

•

Typical

finish 125-250 microns

•

Smaller

kerf size reduces material wastages

•

No

heat affected zone

•

Localises

structural changes

•

No

cutter induced metal contamination

•

Eliminates

thermal distortion

•

No

slag or cutting dross

•

Precise,

multi plane cutting of contours, shapes, and bevels of any angle.

3.5 Limitations of abrasive water jet cutting

•

Cannot

drill flat bottom

•

Cannot

cut materials that degrades quickly with moisture

•

Surface

finish degrades at higher cut speeds which are frequently used for rough cuts

The

major disadvantage s of abrasive water jet cutting are high capital cost and

high noise levels during operation.

A

component cut by abrasive water jet cutting is shown in Figure .As it can be

seen, large parts can but cut with very narrow kerfs which reduces ma terial

wastages. The complex shape part made by abrasive water jet cutting

3.6.

Abrasive water jet cutting

•

WJM

- Pure

•

WJM

- with stabilizer

•

AWJM

– entrained – three phase –abrasive, water and air

•

AWJM

– suspended – two phase –abrasive and water o direct pumping

i. Indirect Pumping

ii. Bypass pumping

4.

ULTRASONIC MACHINING (USM)

4.1.

Introduction

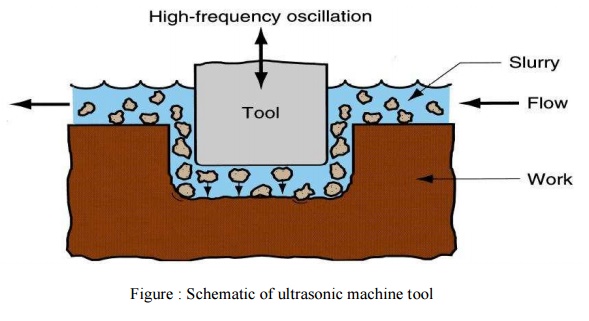

USM is mechanical material removal

process or an abrasive process used to erode holes or cavities on hard or

brittle work piece by using shaped tools, high frequency mechanical motion and

an abrasive slurry. USM offers a solution to the expanding need for machining

brittle materials such as single crystals, glasses and polycrystalline ceramics,

and increasing complex operations to provide intricate shapes and work piece

profiles. It is therefore used extensively in machining hard and brittle

materials that are difficult to machine by traditional manufacturing processes.

The hard particles in slurry are accelerated toward the surface of the work

piece by a tool oscillating at a frequency up to 100 KHz - through repeated

abrasions, the tool machines a cavity of a cross section identical to its own.

USM is primarily targeted for the

machining of hard and brittle materials (dielectric or conductive) such as

boron carbide, ceramics, titanium carbides, rubies, quartz etc. USM is a

versatile machining process as far as properties of materials are concerned.

This process is able to effectively machine all materials whether they are

electrically conductive or insulator.

For an effective cutting operation,

the following parameters need to be carefully considered:

•

The

machining tool must be selected to be highly wear resistant, such as

high-carbon steels.

•

The

abrasives (25-60 µm in dia.) in the (water-based, up to 40% solid volume)

slurry

Includes: Boron carbide, silicon

carbide and aluminum oxide.

Applications

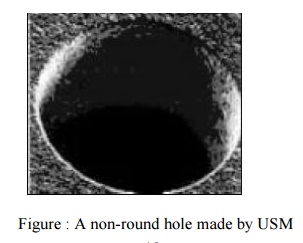

The beauty of USM is that it can

make non round shapes in hard and brittle materials. Ultrasonically machined

non round-hole part is shown in Figure 11.

Figure : A non-round hole made by

USM

4.2Advantage

of USM

USM process is a non-thermal,

non-chemical, creates no changes in the microstructures, chemical or physical

properties of the work piece and offers virtually stress free machined

surfaces.

•

Any

materials can be machined regardless of their electrical conductivity

•

Especially

suitable for machining of brittle materials

•

Machined

parts by USM possess better surface finish and higher structural integrity.

•

USM

does not produce thermal, electrical and chemical abnormal surface

4.3.

Disadvantages of USM

•

USM

has higher power consumption and lower material-removal rates than traditional

Fabrication processes.

•

Tool

wears fast in USM.

•

Machining

area and depth is restraint in USM.

Related Topics