Chapter: Mechanical : Unconventional machining process : Mechanical Energy Based Processes

Abrasive Jet Machining (AJM)

ABRASIVE JET MACHINING (AJM)

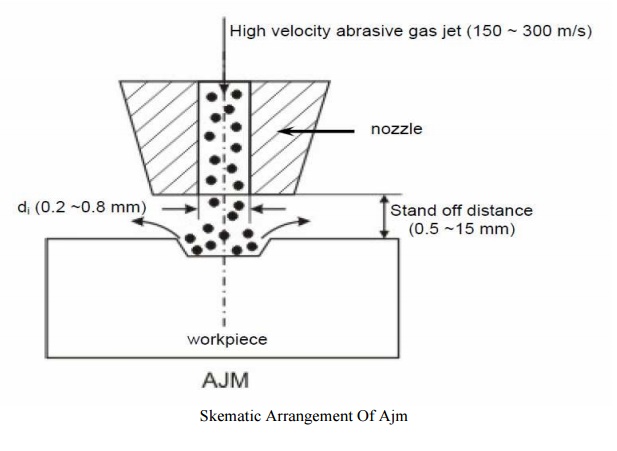

In Abrasive Jet Machining (AJM), abrasive particles are made to impinge on the work material at a high velocity. The high velocity abrasive particles remove the material by micro-cutting action as well as brittle fracture of the work material.

In AJM, generally, the abrasive particles of around 50 μm grit size would impinge on the work material at velocity of 200 m/s from a nozzle of I.D. of 0.5 mm with a standoff distance of around 2 mm. The kinetic energy of the abrasive particles would be sufficient to provide material removal due to brittle fracture of the work piece or even micro cutting by the abrasives.

1. Process Parameters and Machining Characteristics

Abrasive: Material – Al2O3 / SiC / glass beads

Shape – irregular / spherical

Size – 10 ~ 50 μm

Mass flow rate – 2 ~ 20 gm/min

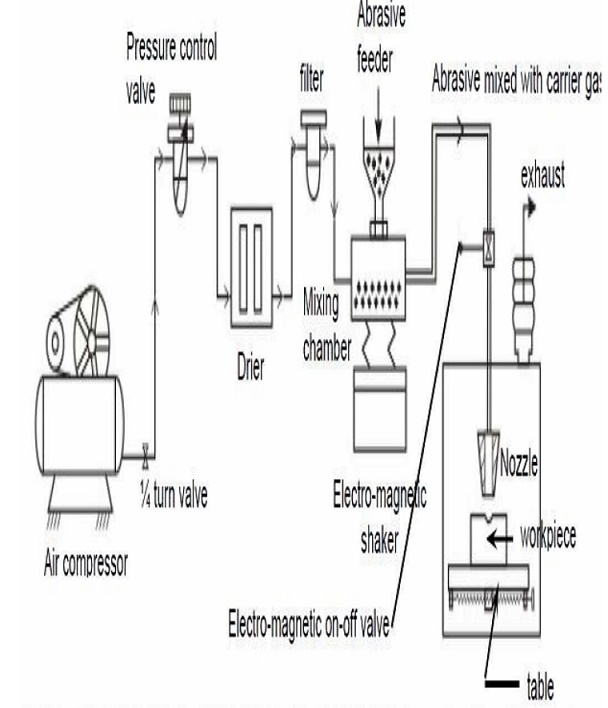

Carrier gas: Composition – Air, CO2, N2

Density – Air ~ 1.3 kg/m3

Velocity – 500 ~ 700 m/s Pressure – 2 ~ 10 bar

Flow rate – 5 ~ 30 lpm

Abrasive Jet : Velocity – 100 ~ 300 m/s

Mixing ratio – mass flow ratio of abrasive to gas

Stand-off distance – 0.5 ~ 5 mm

Impingement Angle – 60 ~ 90

Nozzle: Material – WC

Diameter – (Internal) 0.2 ~ 0.8 mm

Life – 10 ~ 300 hours

.2. Modeling of material removal

Material removal in AJM takes place due to brittle fracture of the work material due to impact of high velocity abrasive particles.

3. Modeling has been done with the following assumptions:

(i) Abrasives are spherical in shape and rigid. The particles are characterized by the mean grit diameter

(ii) The kinetic energy of the abrasives are fully utilized in removing material

(iii) Brittle materials are considered to fail due to brittle fracture and the fracture volume is considered to be hemispherical with diameter equal to choral length of the indentation

(iv) For ductile material, removal volume is assumed to be equal to the indentation volume due to particulate impact

Related Topics