Chapter: Civil : Railway Airport Harbour Engineering : Railway Engineering : Ballast

Laboratory Tests for Physical Properties of Ballast

Laboratory Tests for

Physical Properties of Ballast

The following tests are

recommended to judge the suitability of the ballast material for a railway

track.

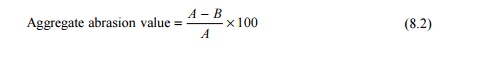

1 Aggregate Abrasion Value

To check for aggregate abrasion,

a test sample of 10 kg of clean ballast conforming to the following grading is

taken

Passing the 50-mm sieve and retained on the 40-mm square mesh

sieve: 5000 g Passing the 40-mm and retained on the 25-mm square mesh sieve:

5000 g The sample, along with the abrasive charge, is placed in the Los Angeles

machine,

which is rotated at a speed of

30-33 rpm for 1000 revolutions. The sample is sieved and material coarser than

the 1.70-mm sieve is washed, dried, and weighed. The difference between the

original weight (A) and the final weight of the sample (B) is

expressed as a percentage of the original weight of the test sample. This value

is reported as the abrasion value.

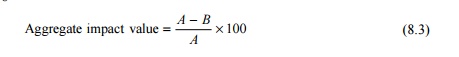

2 Aggregate Impact Value

To check for aggregate impact,

the test sample is prepared out of the track ballast in such a way that it has

a grading that passes the 12.5-mm sieve and is retained on the 10-mm sieve. The

ballast sample is oven dried and placed duly tamped in the different stages in

a cylindrical metal container with 75 mm diameter. and 50 mm depth (weight A).

The cup of the impact testing machine is fixed firmly in position on the base

of the machine and entire test sample is placed in it and compacted by 25

strokes of the tamping rod. The test hammer weighing about 14 kg is raised 380

mm above the upper surface of the cup and dropped. The test sample is subjected

to a total of 15 such blows. The sample is then removed and sieved using a

2.36-mm sieve and the weight of quantity retained is measured (weight B):

3 Flakiness Index

The flakiness index of an

aggregate is the percentage by weight of the particles with a least dimension

(thickness) less than three-fifths of their mean dimension. The test is not

applicable to sizes smaller than 6.3 mm.

Track ballast sample of sufficient

quantity is taken to provide a minimum of 200 pieces, which is weighed (weight A).

The sample consisting of aggregates is sieved as per the prescribed procedure

in a series of sieves. The flaky material is separated and weighed (weight B).

The flakiness index is then determined by the total weight of the material

passing the various sieves, expressed as a percentage of the total weight of

the sample gauged.

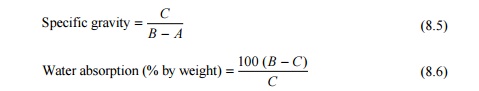

4 Specific Gravity and Water Absorption

Test

A sample consisting of at least

2000 g of aggregate is washed thoroughly to remove finer particles and dust.

The whole material is then drained, placed in a wire basket, and immersed in

distilled water at a temperature between 22 o C and 32 o C. The sample is shaken,

jolted, and dried as per specific procedure. The sample is finally placed in an

oven in a shallow tray at a temperature of 100 o C to 110 o C. It is then removed

from the oven, cooled in the container, and weighed (weight C). The

specific gravity and water absorption is calculated as follows:

where A = weight in grams

of saturated aggregate in water, B = weight in grams of saturated dry

aggregate in air, and C = weight in grams of oven-dried aggregate in

air.

Related Topics