Chapter: Civil : Railway Airport Harbour Engineering : Railway Engineering : Ballast

Design of Ballast Section

Design of Ballast Section

The design of the ballast section

includes the determination of the depth of the ballast cushion below the

sleeper and its profile. These aspects are discussed below.

1 Minimum Depth of Ballast Cushion

The load on the sleeper is

transferred through the medium of the ballast to the formation. The pressure

distribution in the ballast section depends upon the size and shape of the

ballast and the degree of consolidation. Though the lines of equal pressure are

in the shape of a bulb, yet for simplicity, the dispersion of load can be

assumed to be roughly 45 o to the vertical. In order to ensure that the load is

transferred evenly on the formation, the depth of the ballast should be such

that the dispersion lines do not overlap each other.

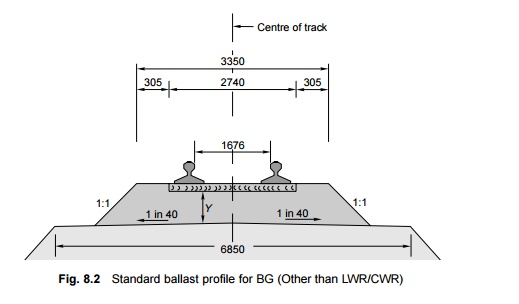

For the even distribution of load on the formation, the depth

of the ballast is determined by the following formula (refer to Fig. 8.1):

Fig. 8.1 Minimum depth

of ballast cushion (dimensions in mm)

Sleeper spacing = width of the sleeper + 2 × depth of ballast (8.1) If a BG track is laid with wooden

sleepers with a sleeper density of N + 6, then the sleeper spacing would

be 68.4 cm. If the width of the sleeper is 25.4 cm, then the depth of the

ballast cushion would be

A minimum cushion of 15-20 cm of ballast below the

sleeper bed is normally prescribed on Indian Railways.

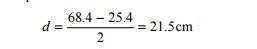

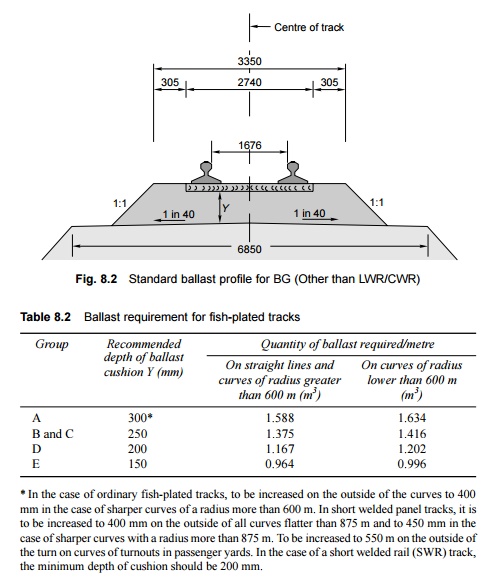

2 Ballast Profile for Fish-plated Track

The ballast profile for a fish-plated track is shown in Fig.

8.2. The requirements of ballast for different groups of railway lines as

adopted by Indian Railways are given in Table 8.2.

* In the case of ordinary

fish-plated tracks, to be increased on the outside of the curves to 400 mm in

the case of sharper curves of a radius more than 600 m. In short welded panel

tracks, it is to be increased to 400 mm on the outside of all curves flatter

than 875 m and to 450 mm in the case of sharper curves with a radius more than

875 m. To be increased to 550 m on the outside of the turn on curves of turnouts

in passenger yards. In the case of a short welded rail (SWR) track, the minimum

depth of cushion should be 200 mm.

3 Ballast

Profile for Long Welded Rail Tracks

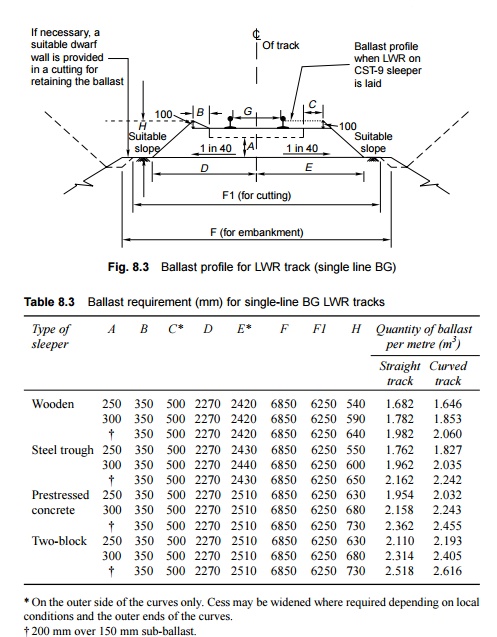

The ballast profile for a long

welded rail (LWR) track is shown in Fig. 8.3. The requirements of ballast for

different types of sleepers on a BG railway line are given in Table 8.3.

The minimum clean stone ballast cushion below the bottom of

sleeper (A) is 250 mm. For routes where speeds are to be more than 130

kmph, A is 300 mm- 200 mm along with 150 mm of sub-ballast. Suitable

dwarf walls should be provided in the case of cuttings, if necessary, for

retaining the ballast.

* On the outer side of the curves

only. Cess may be widened where required depending on local conditions and the

outer ends of the curves.

† 200 mm over 150 mm sub-ballast.

Related Topics