Chapter: Design of Electrical Machines : Introduction

Important Short Questions and Answers: Design of Electrical Machines - Introduction

INTRODUCTION

1.What

are the types of electrical engineering materials?

Basically there are three types of

materials used in electrical machines.

Ø

Magnetic

materials

Ø

Conducting

materials

Ø

Insulating

materials

2.What

is meant by critical magnetic field?

If the temperature of a material is

raised above its critical temperature its superconductivity disappears. The

field at which superconductivity vanishes is called critical magnetic field.

3. What is askarel?

An askarel is a synthetic non

flammable insulating liquid. The commonest askarel is hexa choloro diphynyl

tricholoro benzene.

4.

Name the magnetic materials used for

Yoke, Transformer Stampings and permanent magnet.

Yoke of a dc machine, transformer

stamping, permanent magnet Yoke of a dc machine – cast steel

Transformer stamping – silicon steel

Permanent magnet – hard magnetic

material (Al, Ni, Co)

5.

Comment on the use of CRGOS strip

wound transformer core.

CRGOS means cold rolled grain

oriented steel. This steel is manufactured by series of cold reductions and

intermediate annealings. This could reduce the material has strong directional

of highest permeability which results less hysteresis loss. This type of

material is suitable for use in transformers.

6. What is meant by heating?

The temperature of a machine rises when

it runs under load condition starting from cold condition. The temperature

raises is directly proportional to the power wasted. The heat dissipation may

be due to conduction, convection or radiation.

7. What is meant by cooling?

The cooling medium like air, water

or gas is provided to absorb the heat energy to save the machine. The cooling

medium is also called coo lent. The cooling is of two types like, direct and

indirect cooling.

8. What is meant by radiation?

If the heat energy is transferred from

one place to other with air of gas it is called radiation.

9.

What are the electrical properties

of insulating materials?

Ø

high

dielectric strength

Ø

high

resistivity

Ø

low

dielectric hysteresis

Ø

good

thermal conductivity

Ø

high

thermal stability

10.

Classification of insulating

materials.

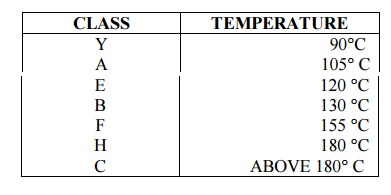

There are seven classes of

insulating materials used in electrical machines according to their thermal

stability in service.

11.

What are the constructional elements of a transformer?

The constructional elements of a

transformer are core, high and low voltage windings, cooling tubes or radiators

and tank.

12.

How the design problems of an

electrical machine can be classified?

The design problems of electrical

machine can be classified as:

Ø

Electromagnetic

design

Ø

Mechanical

design

Ø

Thermal

design

Ø

Dielectric

design

13.

List the constructional elements of

a d.c. machine?

The major constructional elements of

a d.c.machine are stator, rotor, brushes and brush holders. The various parts

of stator and rotor are listed below:

Stator

-

Yoke (or) Frame

Field pole

Pole shoe

Field winding

Interpole

Rotor

-

Armature core

Armature winding

Commutator

14.

How is total m.m.f. calculated?

The total mmf required to establish

the flux in the magnetic circuit is calculated using the knowledge of

dimensions and configuration of the magnetic circuit. The magnetic circuit is

split up into conventional parts, which may be connected in series or parallel.

The flux density is calculated in every part and m.m.f. per unit length; ‘at’

is found by consulting ‘B-H’ curves. The summation of m.m.fs in series gives

the total m.m.f.

15.

List the methods used for

determining the motor rating for variable load drives.

Ø

Method

of average losses

Ø

Equivalent

current methods

Ø

Equivalent

torque method

Ø

Equivalent

power method

16.

Define rating.

Rating of a motor is the power

output or the designated operating power limit based upon certain definite

conditions assigned to it by the manufacturer.

17.

What are the problems that arise during the calculation of m.m.f. for air gap?

The iron surfaces around the air gap

are not smooth and so the calculation of m.m.f. for the airgap by ordinary

methods gives wrong results. The problem is complicated by the fact that

Ø

One

or both of the iron surfaces around the air gap may be slotted so that the flux

tends to concentrated on the teeth rather than distributing itself uniformly

over the air gap.

Ø

There

are radial ventilating ducts in the machine for cooling purposes which effect

in a similar manner as above.

Ø

In

salient pole machine, the gap dimensions are not constant over whole of the

pole pitch.

18.

Mention the methods used for

calculating the mmf for tapered teeth.

Ø

Graphical

method

Ø

Three

ordinate method ( Simpson’s Rule)

Ø

Bt

1/3 Method

19.

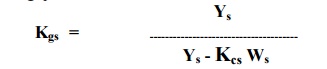

What is Carter’s gap co-efficient?

The Carter’s gap co-efficient ( Kcs)

is the ratio of slot width to gap length. The formula which gives the value of

Kcs directly is

Kcs = 1 / [1 + (5 lg/Ws )]

Where lg = gap length; Ws

= Width of slot

The other formula for Carter’s gap

co-efficient ( Kcs) for parallel sided open slot is

Kcs = 2/Π [tan-1 y – 1/ Π log SQRT (1+

Π2)]

Where y = Ws / 2 lg.

20.

Write down the expression for

calculation of reluctance of air gap with slotted Armature.

Reluctance of air gap with slotted armature

Sg = lg / µ ys

L = lg /µ0 L (ys - Kcs Ws

)

Where lg = gap length; ys

= slot pitch; Kcs = Carter’s co-efficient; Ws = Width of

slot.

21.

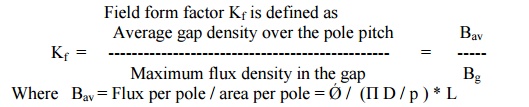

Define field form factor.

22.

Define stacking factor.

Stacking factor is defined as the

ratio of actual length of iron in a stack of assembled core plates to total

axial length of stack.

23.

What is gap contraction factor for slots?

The ratio of reluctance of air gap

of slotted armature to reluctance of air gap of smooth armature is called gap contraction

factor for slots.

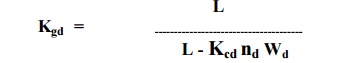

24.

What is gap contraction factor for ducts?

The ratio of reluctance of air gap

with ducts to reluctance of air gap without ducts is known as gap contraction

factor for ducts.

Where

L = Length of core;

Kcd = Carter’s

co-efficient for ducts ;

Nd = number of radial

ducts;

Wd = Width of each duct

25.

Write the expression for mmf of air gap with smooth and slotted armatures.

M.M.F. for air gap with smooth

armature is ATg = 8,00,000 B lg

M.M.F. for air gap with slotted

armature is ATg = 8,00,000 Kg B lg

Where Kg is gap expansion factor; B

is flux density; lg is

gap length.

26.

Mention the problems encountered while calculating the mmf for teeth.

The calculation of mmf necessary to maintain

the flux in the teeth is difficult during to the following problems:

Ø

The

teeth are wedge-shaped or tapered when parallel sided slots are used. This

means that the area presented to the path of flux is not constant and this

gives different values of flux density over the length of teeth.

Ø

The

slot provides another parallel path for flux, shunting the tooth. The teeth are

normally worked in the saturation region and therefore their permeability is

low and as a result an appreciable portion of the flux goes down the depth of

slots.

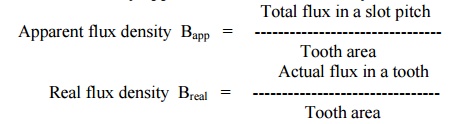

27.

Explain why real flux density in the

teeth is less than the apparent flux density.

The slot provides an alternate path

for the flux to pass, although the flux entering an armature from the air gap

follows paths principally. If the teeth density is high, the mmf acting across

the teeth is very large and as the slots are in parallel with the teeth, this

mmf acts, across the slots also. Thus at saturation density, the flux passing

through the slots become large and cannot be neglected and calculation based on

‘no slot flux’ leads to wrong results. This shows that the real flux passing

through the teeth is always less than the total or apparent flux. As a result,

the real flux density in the teeth is always less than the apparent flux

density.

28.

What is meant by apparent and real flux density?

29.

What is meant by rating of a machine?

The rating of machine refer to the

whole of the numerical values of electrical and mechanical quantities with

their duration and sequence assigned to the machines by the manufacturer and

stated on the rating plate, the machine complying with the specified

conditions.

30.

Mention the different types of duties of a machine.

The following are the types of duty

as per IS : 4722 – 1968 “ Specification for rotating electric machinery”

Ø

S1

= Continuous duty

Ø

S2

= Short time duty

Ø

S3

= Intermittent periodic duty

Ø

S4

= Intermittent periodic duty with

starting

Ø

S5

= Intermittent periodic duty with

starting and braking

Ø

S6

= Continuous duty with intermittent periodic loading

Ø

S7

= Continuous duty with starting and braking

Ø

S8

= Continuous duty with periodic speed changes

31.

Define continuous rating.

The continuous rating of a motor is

defined as the load that may be carried by the machine for an indefinite time

without the temperature rise of any part exceeding the maximum permissible

value.

32.

Define short time rating.

The short time rating of a motor may

be defined as its output at which it may be operated for a certain specified

time without exceeding the maximum permissible value of temperature rise.

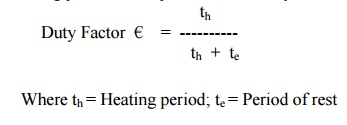

33.

Define duty factor.

The duty factor ( also called load

factor or cyclic duration factor) is defined as the ratio of the heating period

to the period of whole cycle.

34.

What is meant by intermittent

rating?

The intermittent rating of a motor

applies to an operating condition during which short time. Load periods

alternate with period of rest or no load without the motor reaching the thermal

equilibrium and without the maximum temperature rising above the maximum

permissible value.

35.

What are the major considerations to

evolve a good design of electrical machine?

The major considerations to achieve

a good electrical machine are

Ø

Specific

electric loading

Ø

Specific

magnetic loading

Ø

Temperature

rise

Ø

Efficiency

Ø

Length

of air gap

Ø

Power

factor

36.

List the standard specifications for

transformer.

Ø IS 1180 – 1989 : Specifications for out door 3-phase distribution transformer Upto 100 KVA.

Ø

IS

2026 – 1972 : Specifications of power transformers

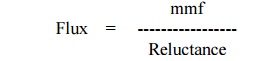

37.

What is magnetic circuit?

The magnetic circuit is the path of

magnetic flux. The mmf of the circuit creates flux in the path against the

reluctance of the path. The equation which relates flux, mmf and reluctance is

given by

38.

Write any two essential differences

between magnetic and electric circuits.

Ø

When

the current flows in the electric circuit the energy is spent continuously,

whereas in magnetic circuit the energy is needed only to create the flux but

not to maintain it.

Ø

Current

actually flows in the electric circuit, whereas the flux does not flow in a

magnetic circuit but it is only assumed to flow.

39.

What is magnetization curve?

The magnetization curve is a graph

showing the relation between the magnetic field intensity, H and the flux

density, B of a magnetic circuit. It is used to estimate the mmf required for

flux path in the magnetic material and it is supplied by the manufacturers of

stampings and laminations.

40.

What is loss curve?

The loss curve is a graph showing

the relation between iron loss and magnetic field intensity, H. It is used to

estimate the iron loss of the magnetic materials and it is supplied by the

manufacturers of stampings and laminations.

41.

What is the difference in

permeability of magnetic and non-magnetic materials?

In magnetic materials the

permeability is not constant and it depends on the saturation of the magnetic

material. But in non-magnetic materials the permeability is constant.

42.

How to find total mmf in a series

circuit?

The various steps in estimation of

mmf of a section of magnetic circuit are:

Ø

Determine

the flux in the concerned section.

Ø

Calculate

the area of cross-section of the section.

Ø

Calculate

the flux density in the section

Ø

From

B – at curve of the magnetic material, determine the mmf per meter(at) for the

calculated flux density

Ø

The

mmf of the section is given by the product of length of the section and mmf per

metre.

43.

List the different types of slots

that are used in rotating machines.

The different types of slots are

Ø

Parallel

sided slots with flat bottom

Ø

Parallel

sided slots with circular bottom

Ø

Tapered

slots with flat bottom

Ø

Tapered

slots with circular bottom

Ø

Circular

slots

44. Mention

the undesirable effects of unbalanced magnetic pull.

The undesirable effects of unbalanced

magnetic pull are

Ø

Saturation

of magnetic materials due to reduction in air gap.

Ø

Excessive

vibration and noise due to unbalanced radial forces

45.

Mention the importance of conductor

dimensions.

The dimension of the conductors

directly affects the following factors in rotating machines:

Ø

Allowable

temperature rise

Ø

Resistivity

Ø

Current

density

Ø

Specific

electric loading

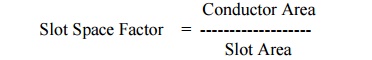

46.

Define slot space factor or slot

insulation factor.

The slot space factor is defined as

the ratio of conductor area to slot area.

47.

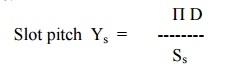

What do you understand by slot pitch?

The slot pitch is defined as the

distance between centers of two adjacent slots measured in linear scale.

Where D = Diameter of armature

Ss = Number of slots in armature

48.

State the parameters governing slot

utilization factor or slot space factor.

The following factors decide the

slot utilization factor:

Ø

Voltage

rating

Ø

Thickness

of insulation

Ø

Number

of conductors per slot

Ø

Area

of cross-section of the conductor

Ø

Dimensions

of the conductor

49.

Define specific permeance of a slot.

Specific permeance of a slot is

defined as the permeance per unit length of slot or depth of field.

50.

What is unbalanced magnetic pull?

The unbalanced magnetic pull is the

radial force acting on the rotor due to non-uniform air-gap around armature

periphery.

Related Topics