Chapter: Chemistry : Electro Chemistry and Corrosion

Important Questions and Answers: Electro Chemistry and Corrosion

Electrochemistry & corrosion.

01. Define an Electrochemical cell. Give one

example.

A cell

which converts chemical energy into electrical energy is known as

electrochemical cell. Example: Daniel cell , Batteries.

02. What do you mean by redox reaction?

Both

reduction and oxidation takes place simultaneously in a cell reaction then it

is known as redox reaction of an electrochemical cell.

03. What is electrode potential?

It is the

measure of tendency of a metallic electrode to lose or gain electrons, when it

is in contact with its own salt solution. It is denoted as “E”

04. Define an origin of electrode potential.

When a

metallic electrode is placed in its own salt solution, two types of reaction

takes place.

+ve ions may pass into the solution. M → Mn+ + ne-

(oxidation)

+ve ions from the solution may deposit over the

metal. Mn+ + ne-→M (reduction)

The above

reaction takes place in an electrode then it is known as an origin of electrode

potential.

05. Define oxidation potential and reduction

potential.

Oxidation

potential: The tendency of a metallic electrode to lose electrons, Reduction

potential: The tendency of a metallic electrode to gain electrons

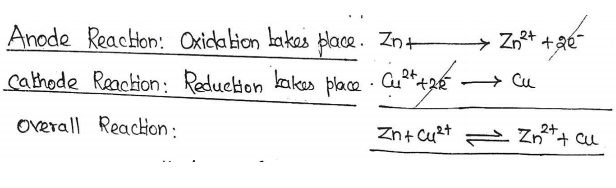

06. How an electrochemical is measured? Define EMF

of an electrochemical cell.

It is

measured by EMF.: “The difference of potential which causes flow of electrons

from one electrode of higher potential to the other electrode of lower

electrode potential”.EMF= ER-EL

07. What are the applications of electrochemical

cell?

Determination

of sparingly soluble salt.,Determination of the valency ion. Determination of

standard free energy change and K.

Potentiometric

titrations can be carried out.,Hydrolysis constant can be determined.

08. Define electrochemical series.

When

various types of metallic electrodes are arranged in their increasing order of

standard reduction potential on the basis of hydrogen scale is known as emf

series.

09. Write the significance of electrochemical

series.

To

calculate the standard emf of the cell.,Relative ease of oxidation or

reduction.

Displacement

of one element by the other., Hydrogen displacement behavior. Determination of

equilibrium constant (K) for the reaction.

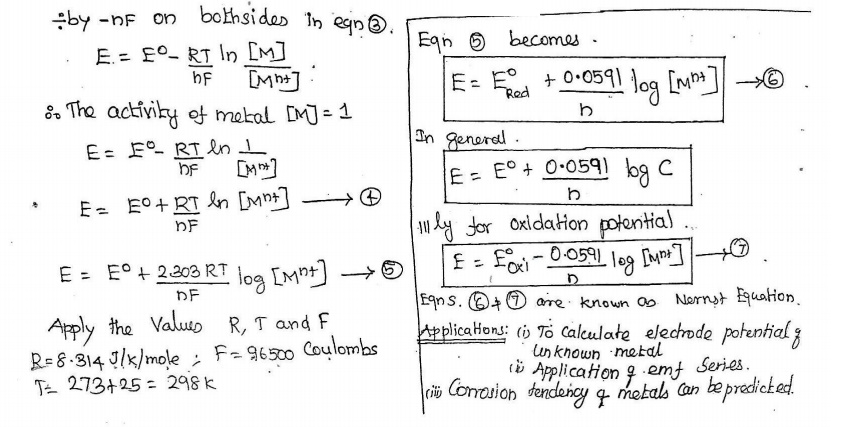

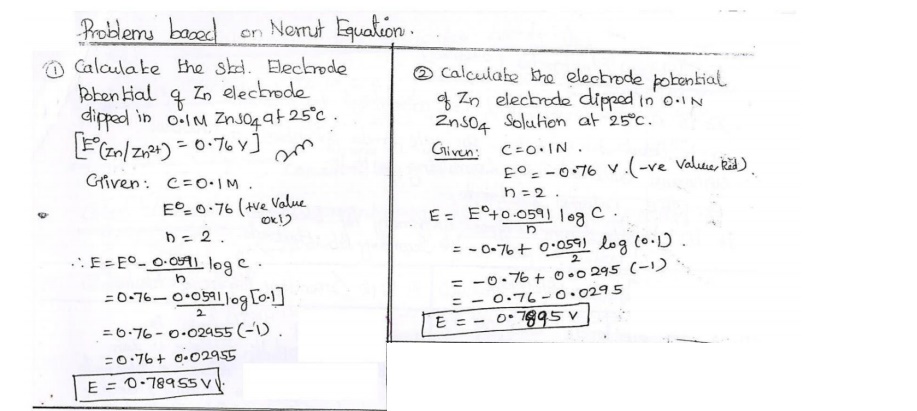

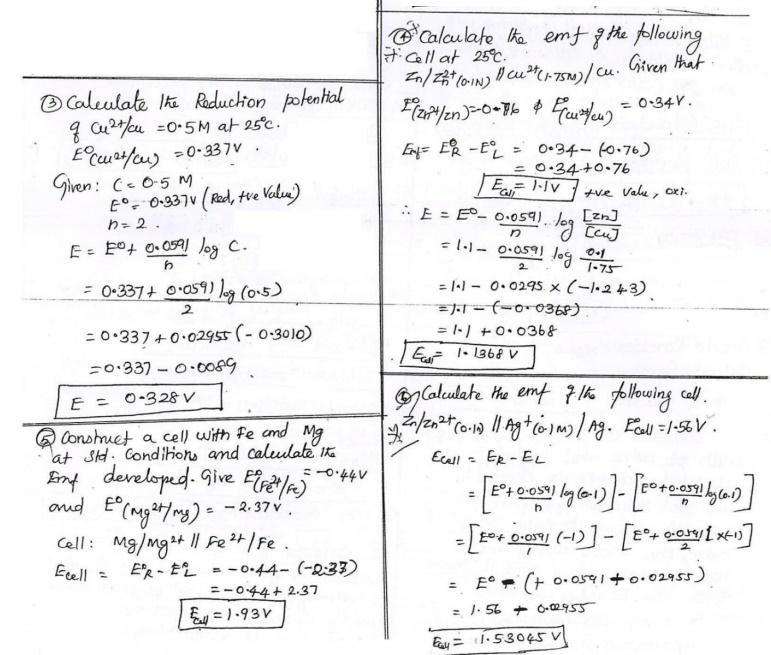

10.Write the mathematical form of Nernst equation

and give one application.

E = Eo +

0.0591/n log [Mn+]

Application:

1.It is used to calculate electrode potential of unknown metal.

Corrosion tendency of metals can be predicted.3.

Applications of emf series.

11.Define corrosion.

The

gradual destruction of the metal or an alloy surface by the chemical or

electrochemical reaction with its environment. (i.e) metal into metal oxide.

12. What are the types of corrosion?

(i).

Chemical corrosion. (ii).

Electrochemical corrosion

13. What are the factors which affect corrosion?

(i).Air and moisture. (ii). Electrolytes in

water.(iii). Presence of impurities in metal. (iv). Presence of gases like CO2

and SO2 (v). Differential aeration.

14. Define chemical corrosion. What are the types

of chemical corrosion?

It is

known as dry corrosion. It is due to the local attack of metal surfaces by the

atmospheric gases like oxygen,H2S,SO2 , N2, etc.

3 types.

(i). Oxidation Corrosion. (ii). Corrosion by other gases. (iii). Liquid-metal

corrosion.

15. Define an Electrochemical

corrosion. What are the types of Electrochemical corrosion?

It occurs due to the existence of separate “anodic”

and “cathodic” areas between which current flows through the conducting

solution. At anodic area oxidation occurs and anodic part of metal is

destroyed. (i). Galvanic corrosion. (ii). Concentration cell / Differential

aeration corrosion.

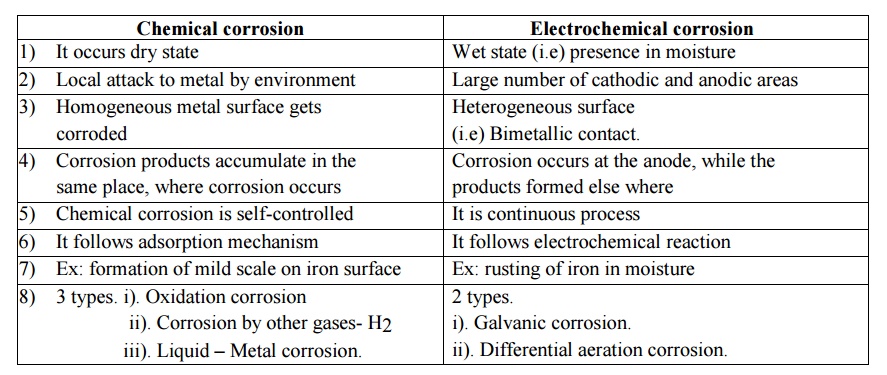

16. What are the differences

between chemical and electrochemical corrosion?

Chemical corrosion

1) It occurs dry state

2) Local attack to metal by environment

3) Chemical corrosion is self-controlled

4) It follows adsorption mechanism

5) Ex: formation of mild scale on iron surface

Electrochemical corrosion

1) Wet

state (i.e) presence in moisture

2) Large

number of cathodic and anodic areas

3) It is

continuous process

4) It

follows electrochemical reaction

5) Ex:

rusting of iron in moisture

17.What isBedworth rule?

The ratio

of the volume of the oxide formed to the volume of the metal consumed is

pilling bedworth rule

18.Bolt and Nut made of the same

metal is preferred in practice . Why?

Because

such a combination will not permit galvanic corrosion to take place.

19.What are the methods used to

control the corrosion?

1.

Sacrificial anodic method 2.Impressed current cathodic metho

20 What is paint?

Paint is

a mechanical dispersion of one or more finely divided pigments in a medium

(thinner + vehicle) .When paint is applied to a metal surface, the thinner

evaporates, while the vehicle undergoes slow oxidation forming a pigmented

film.

21.Differenciate Electroplating

and Electro less plating

Electroplating

It is

carried out by passing current

Separate

anode is employed

Anodic

reaction is M → Mn+ + ne-

Thickness

of the plating is 1-100μm

Electroless plating

Used

reducing agent

Catalytic

surface of the substrate acts as an anode

Anodic

reaction is R → 0 + ne-

It has a

thickness of 1-100μm

22. Define Electro plating and Electroless

plating

Electro

plating:

It‟s a process in which the coating metal is

deposited on the base metal by passing a direct current through an electrolytic

solution containing the soluble salt of the coating metal.

Electro

less plating:

It is a technique

of depositing of a noble metal from its salt solution on a catalytically active

surface of a base metal by using a suitable reducing agent.

PART B

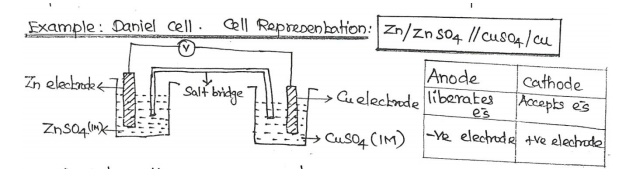

1. What

is electrochemical cell? Explain with example of Daniel cell.

Electrochemical cell: Cells in which the e-s

transferred due to redox reaction and converted into electrical energy.

Example : Daniel cell.

Daniel

cell consists of two electrodes like Zn and Cu.

Zinc

electrode is dipped in 1M ZnSO4 solution and Cu electrode dipped in 1M CuSO4

solution.

The two

solutions are inter connected by a salt bridge and two electrodes are connected

by a wire through the volt meter.

Each

electrode is known as half-cell.

The e-s

liberates from Zn electrode flow through the external wire and is consumed by

copper ions at the cathode.

Salt

Bridge: U- tube containing saturated solution of KCl in agar-agar gel. It

connects two half cells.

Function

of salt bridge: It eliminates liquid junction potential and electrical

continuity between two half cells.

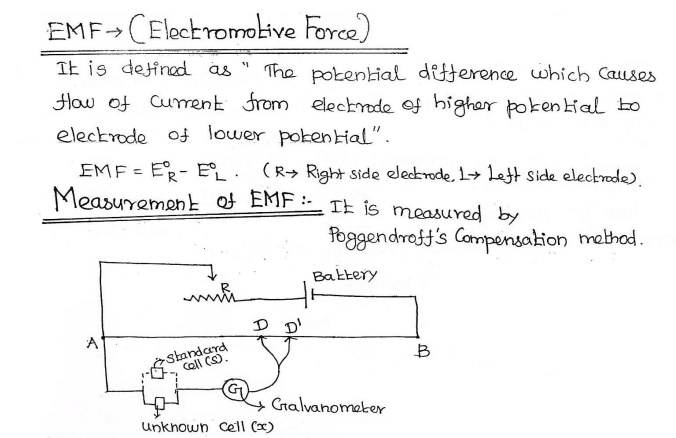

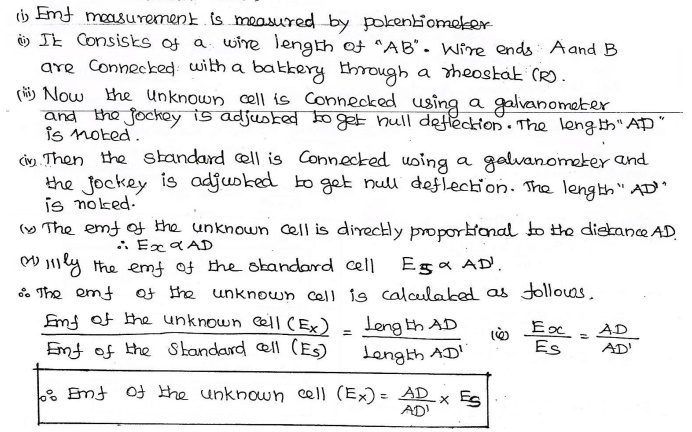

How electrochemical cell is measured by

potentiometrically? Or What is emf? How emf is measured by pogendroff’s method?

03. What are electrochemical series? Give its

applications.

Electrochemical

series: An arrangement in which the standard electrode reduction potential of

different metals are arranged in increasing order on the basis of

hydrogen

scale is known as emf series.

Applications

of EMF series: (i). To calculate the std. emf of a cell.

(ii).

Relative ease of oxidation or reduction. (iii). Displacement of one element by

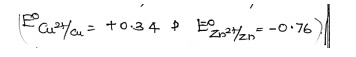

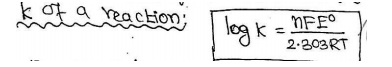

other. (iv). To determine K of a reaction.

(v). Hydrogen displacement from acid solutions.

(vi). Predicting spontaneity of

redox reations.

(i). To

calculate the std. emf of a cell.

The emf of a cell is calculated as follows, Ecell = ER-EL

(ii). Relative ease of oxidation or reduction.

+ve value

– higher reduction potential – high reduction. F- = 2.87, higher

reduction – get oxidized

Li+ = -3.07, lower reduction – high oxidation.

(iii). Displacement of one

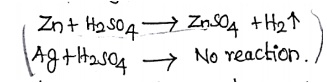

element by other.

Metals

which lie higher in the series can displace those elements which lie below them

in the series. Cu can easily displaced by Zn

(iv).

Determination of Equilibrium Constant K of a reaction.

From the

value of Eo, we can be determined the equilibrium constant K (v)

Hydrogen displacement Behavior

Metals

with above H2 scale will displace the hydrogen from an acid solution (ie)-ve

reduction potential. Zinc reacts with hydrogen but not in Ag. Why?

Because

it has positive reduction potential

(vi)

Predicting Spontaneity of Redox

Reactions:

Eo

value is positive=Reaction is Spontaneous

Eo

value is –ve =Non-Spontaneous Process.

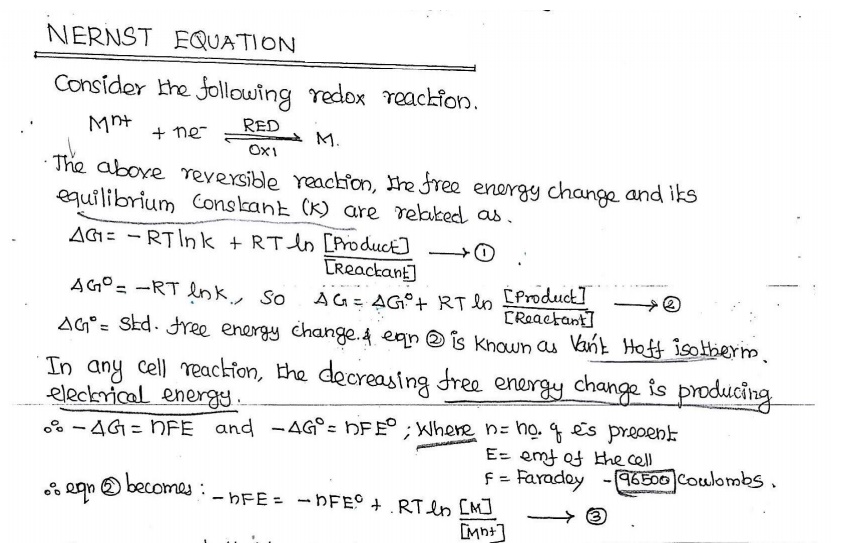

![]() 04. Derive Nernst equation.

04. Derive Nernst equation.

Applications:

To calculate electrode potential of unknown metal

Application of emf series

Corrosion tendency of methods can be predicted

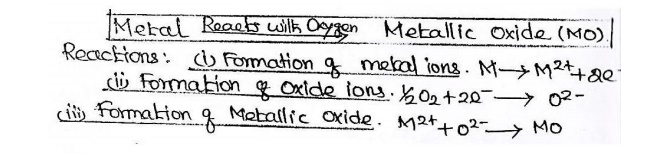

What is Chemical corrosion? Explain with its types.

It is

classified into 3 types. i). Oxidation corrosion.

ii).Corrosion

by the other gases – Hydrogen iii).Liquid – Metal corrosion

01. Oxidation

corrosion

Oxygen

present in atmosphere attacks metal surface resulting in the formation of

metallic oxide which is a corrosion product and known as oxidation corrosion.

Oxidation

occurs first at the surface of the metal and the resulting metal oxide scale

forms a barrier that tends to restrict either further oxidation. For oxidation

to continue either the metal must diffuse outwards through the scale to the

surface or the oxygen must diffuse inwards through the scale, to the underlying

metal.

Both

transfer occurs, but the outward metal diffusion is generally, much more rapid

than the inward diffusion of oxygen. Since the metal ion is appreciably smaller

than the oxygen ion and consequently of much higher mobility.

02.

PILLING – BEDWORTH RULE:

The ratio

of the volume of the oxide formed to the volume of the metal consumed is

pilling bed worth rule.

03.

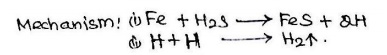

Corrosion by other gases – Hydrogen.

i) At

ordinary Temperature : Hydrogen Embrittlement.

The

process of formation of cracks and blisters on the metal surface, due to high

pressure of hydrogen gas is called hydrogen embrittlement

Metal direct contact with H2s and forms atomic hydrogen

l direct contact with H2s and forms atomic hydrogen

Atomic hydrogen diffuses readily into metal to form

molecular hydrogen

At high temperature – Decarburization

The

process of decrease in carbon content in steel is termed as decarburization of

steel.

04)

Liquid – metal corrosion

This is

due to the chemical action of following liquid metal at high temperature. The

corrosion reaction involves

Either

dissolution of a solid metal by a liquid metal.

Liquid metal may penetrate into the solid metal.

Explain

Electrochemical corrosion with its types.

01.

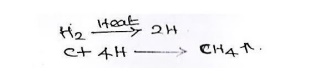

Galvanic corrosion:

The

corrosion occurs when two different metals are in contact with each other in

presence of an aqueous electrolyte solution or moisture is known as Galvanic

corrosion.

The more

active metal acts an anode the less active and metal acts as a cathode

In Zn-Fe

bimetallic couple, Zn undergoes to corrosion, because compare with Fe, it has

higher –Ve emf Value. So it acts as an anode. Iron acts as cathode and it is

protected.

But in

the case of Fe – copper bimetallic couple Fe dissolves and copper is protected.

(ie) Fe acts an anode and copper as a cathode.

Prevention

of Galvanic corrosion:

To prevent

Galvanic corrosion, the bolt and but are made by same metal. If they are n‟t

corrosion will take place easily.

It may be

minimized by putting an insulating material between the two metals.

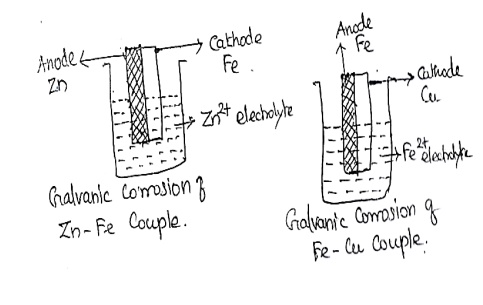

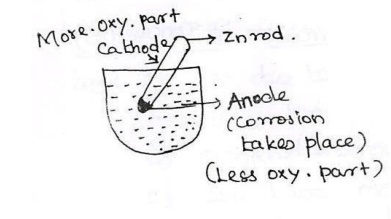

02.

Differential aeration corrosion:-

Otherwise it is known as concentration cell corrosion.

It is due

to the formation of concentration cell formed by the variation of concentration

mainly of oxygen or any electrolyte on the surface of the base metal.

i).When a

metal is partially immersed in a solution, the metal inside the solution has

very poor aeration compared with the metal that is outside the solution.

ii).The difference in the air concentration of

the base metal can produce the anode with less aerated area and cathode.

iii).Corrosion

will take place at the anode area where the metal is converted into metal ion.

Example: A zinc metal partially dipped in a brackish solution.

Example:

Pitting Corrosion - The holes are formed at corrosion in concentrated places.

Low oxygen part= anode , More oxygen part=cathode.

It is a

localized attack, resulting in the formation of a hole around which the metal

is relatively unattached. Ex: metal area covered by a drop of water, sand,

dust, etc.

07. Distinguish between Chemical corrosion and

Electrochemical corrosion.

Chemical corrosion

1) It occurs dry state

2) Local attack to metal by environment

3) Homogeneous metal surface gets corroded

4) Corrosion products accumulate in the same

place, where corrosion occurs

5) Chemical corrosion is self-controlled

6) It follows adsorption mechanism

7) Ex: formation of mild scale on iron

surface

8) 3 types. i). Oxidation corrosion

ii). Corrosion by other gases- H2

iii). Liquid – Metal corrosion.

Electrochemical corrosion

1) Wet

state (i.e) presence in moisture

2) Large

number of cathodic and anodic areas

3)

Heterogeneous surface (i.e) Bimetallic contact.

4)

Corrosion occurs at the anode, while the products formed else where

5) It is

continuous process

6) It

follows electrochemical reaction

7) Ex:

rusting of iron in moisture

8) 2

types.

i).

Galvanic corrosion.

ii).

Differential aeration corrosion.

08. What are the factors influencing corrosion?

The rate

of corrosion is mainly depends on i)

Nature of

the metal

Nature of the environment

i). Nature

of the metal

a).

Position in emf series: Metals above hydrogen in emf series, corroded

easily.

Metals

have high –ve reduction potential undergoes corrosion.

Relative areas of the anode and cathode: Rate of

the corrosion has higher % in anodic area, the rate of corrosion will be more,

when the cathodic area is larger.

Purity of the metal: The 100%

pure will not undergo any type of corrosion. If

impurity

present in higher percentage, corrosion takes places at anode.

d) Over

voltage: Corrosive environment is inversely proportional to corrosion rate. e)

Nature of the surface film: It is known as pilling- bed worth rule.

f) Nature

of the corrosion product: Corrosion is faster when the corrosion product is

soluble in corroding medium. If the corrosion product is volatile, the

corrosion rate will be faster.

ii).

Nature of the environment:

i).

Temperature: Rate of corrosion α temperature.

The rate

of corrosion increase with temperature

ii).

Humidity: If the humidity is high in the environment, corrosion will be more.

iii).

Presence of corrosive gases: The acidic gases like

CO2,SO2,H2S are produce electrolytes, which are acidic and increases the

electrochemical corrosion.

iv).

Presence of suspended particles: Particles like NaCl present in

the moisture and acts a

powerful

electrolyte and then enhance the electrochemical corrosion.

v).

Effect of pH; the rate of corrosion will be maximum when the

corrosive environment is acidic (ie) PH<7.

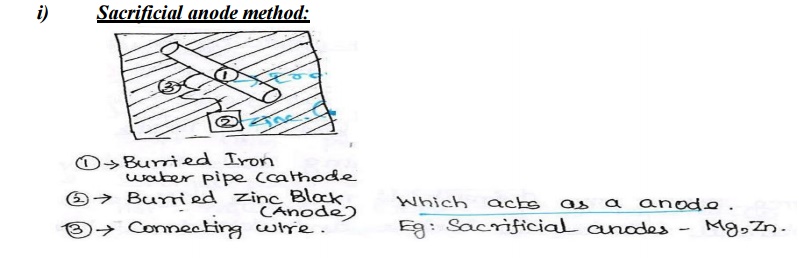

Explain the Sacrificial anode and impressed current

techniques for the preventions of corrosion.

i). The

application of sacrificial anodes in cathodic protection is based on the

differences in electrochemical reactivity of metals.

ii). In

this method, the metal to be protected from corrosion is connected to more

active metal which acts as an anode.

iii). In

a redox reaction involving iron and zinc, the zinc will serve as the anode, and

iron the cathode.

iv). The

zinc anode will oxidize and provide electrons for the reduction of Fe2+

to elemental iron. v). This is called cathodic protection. The zinc anode is

termed a sacrificial anode.

vi). Iron

pipes buried in the ground, and designed to carry water, would normally be

expected to rust pretty quickly.

vii).If

they are buried along with a piece of zinc, and connected by a wire the zinc

will provide cathodic protection.

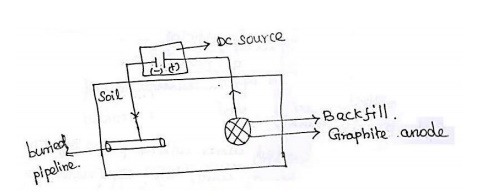

2.

Corrosion control through Impressed current method:

An

alternative method of providing the current to protect a system is to use some

sort of external power supply. As with the sacrificial system , the structure

to be protected is made the cathode, the difference being that the driving

force. Behind the current is not the difference in potential between the anode

and cathode of the system but from the power supply.

Both

these types of cathodic protection may be applied to buried pipelines and to

steel hulled ships. For oil drilling platforms, however the method employed is

sacrificial in the vast majority of cases in the north sea.

This

technique is useful for protecting large structures like water tanks,

underground oil collers, laid up ships,etc.

10. What is paint? What are the constituents and

their functions in paint?

Paint: paint is a mechanical dispersion

of one or more finely divided pigments in a medium (thinner + vehicle) . When paint is applied to a

metal surface, the thinner evaporates, while the vehicle undergoes slow

oxidation forming a pigmented film.

Constituents:

1.

Pigments. 2. Vehicle or drying oil. 3. Thinner. 4. Drier. 5. Filler or

extender. 6. Plasticizer 7. Antiskinnig agent.

i) Pigments: They are colour producing

substances in paint.

Ex: white

colour- white lead, black=- carben black red-indian red, green – chromium

oxide.

Function: i). It gives colour and opacity to the

film. ii). It also provides strength to the film.

iii). It

provides weather resistance of the film.

ii) Vehicle

(or) drying oil: This is a non-volatile portion of a medium and film

forming constituent of the paint. These are high molecular weight fatty acids

present in vegetable and animal oils. Ex: Linseed oil, castor oil.

Function:

They form a protective film by the oxidation and

polymerization of the oil ii) They hold the pigment particles together on the

metal surface

They impart water repellency , toughness and

durability to the film.

Thinners or solvents: Thinner

is a volatile substance present in the medium.

Ex: turpentine, toluol, xylol etc.

Function:

It increases the elasticity of the film

II) It helps easy drying of the paint

film

It increases the penetrating power of the vehicle.

Extenders or fillers: These

are colourless (white) pigments which improve the quality of the paint. Ex:

Gypsum, Jal ,china clay, silica, etc.

Functions:

It reduces the cost of paint

It prevents the cracking and shrinkage of the film

iii) It modifies the shades of the pigments

v).Driers: these are the substances, used

to accelerate the process of crying. Ex: metallic soaps.

Functions: i).They are oxygen –carriers (or) catalists.

ii). They

provide oxygen , which is essential for oxidation, polymerization of drying

oil. vi).Plasticisers: these are chemicals added to the paint to provide

elasticity to the film and to prevent cracking of the film. Ex: triphenyl

phosphate, tricresyl phosphate, etc.

vii).

Antiskinning agents: These are chemicals added to the paint to prevent

gelling and skinning of the paint. Ex: polyhydhroxy phenol.

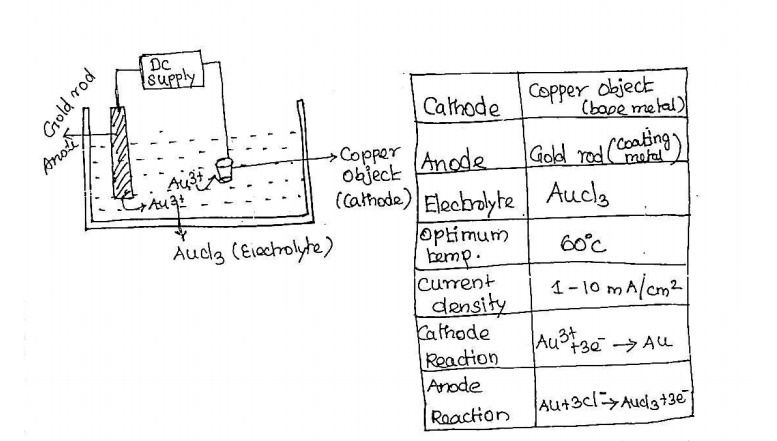

11. Explain the electroplating of Gold.

Electroplating: It‟s a

process in which the coating metal is deposited on the base metal by passing a

direct current through an electrolytic solution containing the soluble salt of

the coating metal.

Ex:

Electroplating of Au (gold) over copper object.

The

copper object to be plated is first treated with dilute acid.

Then this

copper object and gold rod are immersed in an electrolyte. Copper object acts

cathode and gold rod is an anode.

These

electrodes are connected with direct power supply.

When

current is passed from battery through the solution, gold dissolves in

electrolyte and deposits uniformly in copper object.

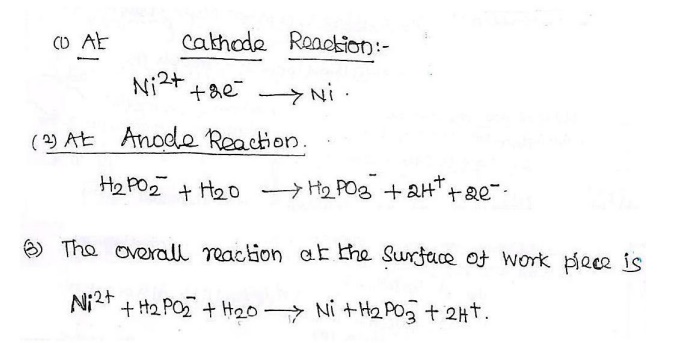

12. Explain the Electroless plating of Nickel.

Metal

ions + Reducing Agent Metal (Deposited) +

Oxidised Product

Definition: it is a

technique of depositing of a noble metal from its salt solution on a

catalytically active surface of a base metal by using a suitable reducing

agent.

Electroless

Nickel plating:

Step 1:

Pretreatment and activation of the surface:

The

surface to be plated is first degreased by using organic solvents or alkali

followed by acid treatment.

Step 2:

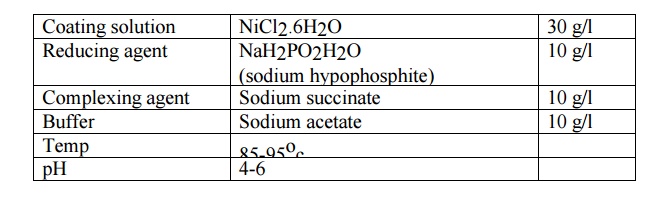

preparation of plating bath composition:

The

pretreated object is immersed in the plating bath for the required time during

which the following reduction reaction will occur and the Ni gets coated over

the object.

GLOSSARY

CELL:

Cell is an assembly of two electrodes and an electrolyte. It

consists of two half cells. Each half cell contains an electrode material in

touch with electrolyte.

CURRENT:

Current is flow of electricity through a conductor. It is measured in ampere.

ELECTRODE:

Electrode is a material or a metallic rod/bar/strip which conducts electrons.

ANODE:

Anode is an electrode at which oxidation occurs.

CATHODE:

Cathode is an electrode at which reduction occurs.

ELECTROLYTIC

CELLS: Electrolytic cells are cells in which electrical energy is converted

into chemical energy.

ELECTOCHEMICAL

CELLS: Electrochemical cells are cells in which chemical energy is converted

into electrical energy.

SALT

BRIDGE: Salt bridge consists of a U – tube containing a gel saturated with KCL

or NH4 NO3 in agar – agar. It consists the two half cells of the

galvanic cells by the electron movement through it.

OXIDATION

POTENTIAL: Electrode lose electrons REDUCTION POTENTIAL: Electrode gain

electrons.

SINGLE

ELECTRODE POTENTIAL: Measure of the tendency of a metallic electrode to lose or

gain electrons, when it is in contact with a solution of its own salt.

STANDARD

ELECTODE POTENTIAL: Measure of the tendency of a metallic electrode to lose or

gain electrons, when it is in contact with a solution of its own salt of a 1

molar concentration at 250C.

ION –

SELECTIVE ELECTRODES: These are electrodes which have the ability to respond

only to a particular ion and develop potential, ignoring the other ions in a

mixture. The potential developed by an ion – selective electrodes depends only

on the concentration of particular ions.

ELECTROCHEMICAL

SERIES: An increasing order of the standard reduction potentials CORROSION:

Corrosion is defined as the gradual destruction of metals by the chemical or

electrochemical reaction with its environment.

PILLING

BEDWORTH RATIO; The ratio of the volume of the oxide formed to the volume of

the metal consumed is called ”Pilling – Bed worth ratio” or “Pilling – Bed

worth rule”.

PAINT:

Paint is a uniform dispersion of finely dived pigments, filters and driers in a

liquid called medium (thinner + vehicle ).When a paint applied to a metal

surface , the thinner evaporates, while the vehicle undergoes slow oxidation

forming a pigmented film.

Related Topics