Chapter: Chemistry : Electro Chemistry and Corrosion

Corrosion

1 Corrosion

1.1 Consequences of corrosion

2 Types of Theories of Corrosion

2.1 Dry or Chemical corrosion

2.2 Wet or electrochemical corrosion

3 Factors influencing the rate of corrosion

3.1 Nature of the metal

3.2 Nature of the environment

4 Corrosion Control

4.1 By modifying metal

4.2 BY modifying the environment

5 Paints

5.1 Characteristics of a good paint

5.2 Constituents and their functions of paints

6 Metallic Coatings

6.1 Electroplating

6.2 Electroless Plating

1 Corrosion

It is the gradual deterioration of metals by

chemical, electrochemical or biochemical interaction with the environment.

Causes of Corrosion

Metals occur in nature as their oxides, sulphides

carbonates etc. The chemically combined state is thermodynamically more stable.

When we extract a metal from its ore, the metal is in a higher energy state,

which is thermodynamically unstable. So it tries to go back to the stable state

by chemical or electrochemical interaction with the environment.

Consequences

or effects of Corrosion

Efficiency of the machine decreases.

Plant has to be shut down due to failure.

Product is contaminated.

The toxic products of corrosion cause health

hazards.

There is a necessity to over design to allow for

corrosion.

2 Types or

Theories of Corrosion

I. Dry or Chemical Corrosion

II. Wet

or Electrochemical Corrosion

2.I. Dry or Chemical Corrosion

It is due

to the attack on metal surface by atmospheric gases like O2, SO2, H2S etc.

(e.g.) Tarnishing of silver by H2S.

There are

three types of dry or chemical corrosion.

Oxidation Corrosion

Corrosion by Hydrogen

Liquid Metal Corrosion

Oxidation Corrosion

It is due

to the direct attack of oxygen on metal surface in the absence of moisture.

Alkali and Alkaline earth metals are corroded at low temperatures. At high

temperatures, most metals except Au, Pt and Ag are oxidized.

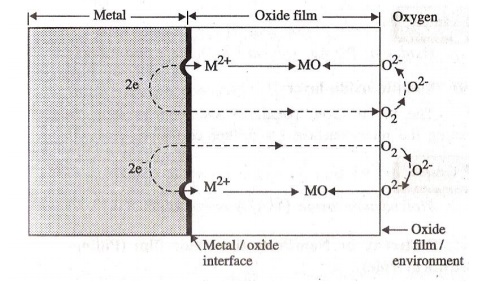

Mechanism

Oxidation occurs at the surface of the metal to

form M2+ ions.

® M2+

+ 2e-

Oxygen takes up the electrons. O2 is reduced to O2-

O2 + 2e-

® O2-

O2- ion reacts with M2+ to

form metal oxide.

M2+

+ O2- ® MO

The metal

surface is converted to a monolayer of

metal oxide. Further corrosion occurs by diffusion of M2+ ion through

the metal oxide barrier. The growth of oxide film is perpendicular to the metal

surface.

Different types of oxide films are formed.

(i) Porous and Non-Porous Oxide Film (or)

Pilling-Bedworth Rule

(a) If

the volume of the oxide layer formed is less than the volume of the consumed,

the oxide layer is porous. (e.g.) The volumes of oxides of alkali and alkaline

earth metals are less than the volume of the metal consumed. So the oxide layer

is porous and non-protective

(b) If

the volume of the oxide layer formed is greater than the volume of the metal

consumed, the oxide layer is non-porous.(e.g.) The volumes of oxides of heavy

metals such as Pb, Sn are greater than the volumes of the metal consumed. So

the oxide layer is non-porous and protective.

(ii) Stable Oxide Layer

A stable

oxide layer is firmly adsorbed on the metal surface. The layer is impervious

and prevents further corrosion. So the layer itself acts as a protective

coating. (E.g.) Oxides of Al, Cu etc.

(iii) Unstable oxide Layer

This is

mainly produced on the surface of noble metals such Ag, Au etc. The unstable

oxide decomposes to stable metal and oxygen. Metal Oxide Metal + Oxygen

(iv) Volatile Oxide

The oxide

film volatilizes as soon as it is formed. It leaves fresh metal surface for

further continuous attack. (e.g.) Molybdenum oxide MoO3.

(2) Corrosion by Hydrogen

Hydrogen embrittlement Definition

It is

formation of cracks and blisters on the metal by hydrogen gas when the metal

comes into contact with H2S. Iron liberates atomic hydrogen by reacting with

H2S.

Fe +

H2S FeS + 2H

Hydrogen

atoms diffuse into the voids of metal matrix. When the pressure of the gas

increases, cracks and blisters develop on the metal.

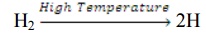

Decarburisation

It is the

process of decrease in the carbon content of steel. At high temperature,

molecular hydrogen decomposes to atomic hydrogen. High Temperature

When steel is exposed to this environment, carbon in the steel reacts with atomic hydrogen.

C + 4H - - > CH4

Hence the

carbon content in steel decreases. Collection of methane gas in the voids of

steel develops high pressure and causes cracking.

(3) Liquid Metal Corrosion

It is due

to the chemical action of flowing liquid metal at high temperature. It involves

:

dissolution of a solid metal by the liquid metal.

Penetration of liquid metal into the solid metal.

2. 2. Wet (or) Electrochemical

Corrosion :

It occurs

under the following conditions.

When two

dissimilar metals or alloys are in contact with each other in presence of an

aqueous solution or moisture.

When the metal is exposed to an electrolyte with

varying amounts of oxygen.

Mechanism of Wet Corrosion

Metal dissolution occurs at the anode.

M → Mn++

+ ne-

Reduction reaction occurs at the cathode in

different environments.

Acidic

environment : Here hydrogen gas is evolved at the cathode.

2 H+ +

2e- → H2

(b)

Neutral environment : In neutral or slightly alkaline medium, hydroxide ions

are formed at the cathode.

½ O2 +

2e- + H2O → 2OH-

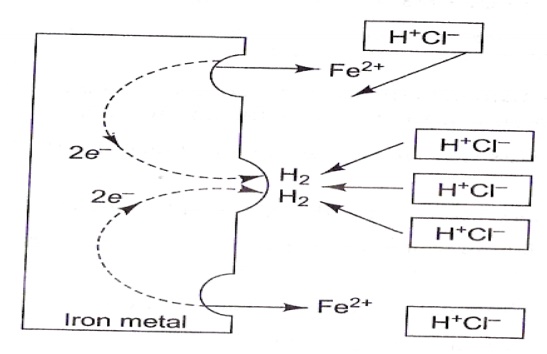

(a) Hydrogen Evolution type

corrosion (In Acidic Medium)

All

metals above hydrogen in the electrochemical series tend to get dissolved

in acidic

solution with simultaneous evolution of H2 gas. e.g.) When iron comes into

contact with non-oxidising acid like HCl, hydrogen evolution occurs.

At anode

: Iron is oxidized to Fe2+

Fe → Fe+2

+ 2e-

At

cathode : H+ ion is reduced to H2.

2 H+ +

2e- → H2

oxygen,

OH- ions are formed.

At anode

: Iron is oxidized to Fe

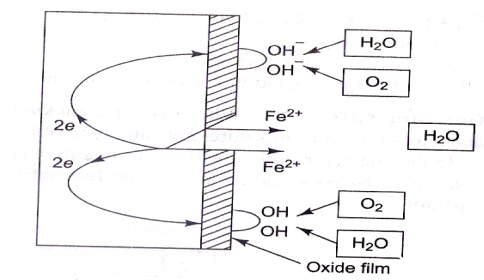

(b) Absorption of Oxygen (or)

Formation of hydroxide ion type corrosion (In neutral or weakly alkaline

medium)

The

surface of iron is normally coated with a thin film of iron oxide. But if some

cracks develop on the film, anodic areas are created on the surface. The rest

of the metal part acts as cathode.(e.g.) When iron is in contact with an electrolyte

solution in presence ofoxygen, OH- ions are formed. At anode : Iron is oxidized

to Fe+2

At

cathode : Production of OH- ions (more aeration) ½ O2 + 2e- + H2O → 2OH

Waterline corrosion

Let us

consider metal tank partially filled up with water. The metal area above water

line is exposed to higher concentration of oxygen (cathode) than the metal

below water level. The metal less exposed to O2 acts as anode and corrodes.

This is called water line corrosion.

Examples of differential aeration

corrosion

Pitting

or localized corrosion

Crevice corrosion

Pipeline corrosion

iv)

Corrosion on wire fence

(i) Pitting Corrosion

It is the

localized attack resulting in the formation of a hole due to corrosion. Example

: Metal area covered by a drop of water, sand, dirt etc.

The area

covered by the drop or dirt acts as anode and corrodes. Theuncovered area

exposed to air or O2 acts as cathode.The rate of corrosion is more if the

cathodic area is larger and anodic area is smaller. Thus more material is

removed from the same area and a pit is formed.

At anode

: Iron is oxidized to Fe+

Fe → Fe2+

+ 2e-

At

cathode : O2 is reduced to OH-. ½ O2 + H2O + 2e- → 2OH Overallreaction :

Fe2+ +

OH- → Fe(OH)

At anode

: Iron is oxidized to Fe+

Fe → Fe2+

+ 2e-

At

cathode : O2 is reduced to OH-. ½ O2 + 2e- + H2O → 2OH

Overall Reaction

Fe+2 +

2OH- → Fe(OH)

If enough

oxygen is present, Fe(OH)2 is oxidized to Fe(OH)2.

4Fe(OH)2 + O2 + H2O → 4Fe(OH)

Differences between chemical

corrosion and electro-chemical corrosion: Chemical Corrosion Electro-chemical

Corrosion

It occurs in dry condition It occurs in presence of

moisture or electrolyte.

It occurs

by the direct chemical attack on the metal by the environment.It occurs by the

formation of a large number of anodic and cathodic areas.

Even a

homogenous metal surface is corroded. Only heterogeneous or bimetallicsurface is

corroded.

Corrosion

products gather at the place of corrosion. Corrosion occurs at the anode, while

the products form elsewhere.

It is a self controlled process It is a continuous

process

It takes

place by adsorption mechanism. It follows electrochemical reaction.(e.g.) Mild

scale formation on iron surface (e.g.) Rusting of iron under moist atmosphere

Types of electrochemical

corrosion

There are

two types:

(i)

Galvanic corrosion

(ii)

Differential aeration or Concentration cell corrosion

(i) Galvanic corrosion

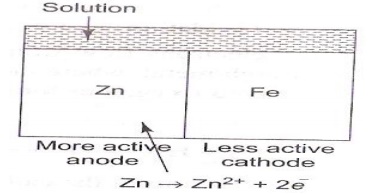

When two

different metals are in contact with each other in presence of aqueous solution

or moisture, galvanic corrosion takes place.

The metal

with more negative electrode potential acts as anode. Metal with less negative

electrode potential acts as cathode. In the Zn-Fe couple as shown in the

figure, zinc with more negative electrode potential, dissolves in preference to

iron. Zn acts as anode and Fe as cathode.

Example :

Steel

screw in a brass marine hardware easily undergoes corrosion. Iron has E0 =

-0.44V. For Cu E0 = +0.34 V. Iron corrodes in preference to Cu.

Prevention

Galvanic

corrosion is minimized by providing an insulation between the two metals.

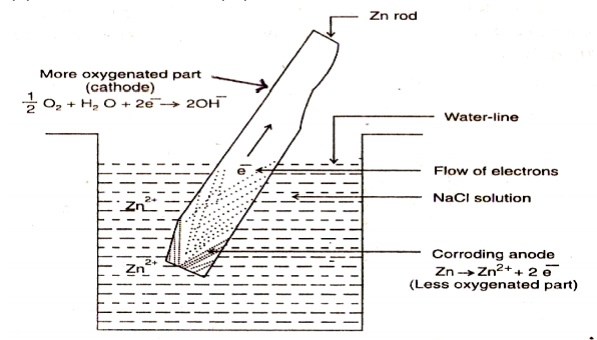

(ii) Differential aeration (or)

concentration cell corrosion

Let a metal be partially immersed in a conducting solution. The part of the metal above the solution is more aerated and acts like cathode. The less aerated metal part inside the solution acts as anode and corrodes.

At anode

: Corrosion occurs (less aeration)

M → M2+ +

2e

At

cathode : Production of OH- ions (more aeration) ½ O2 + 2e- + H2O → 2OH

Wateline corrosion

Let us

consider metal tank partially filled up with water. The metal area above water

line is exposed to higher concentration of oxygen (cathode) than the metal

below water level. The metal less exposed to O2 acts as anode and corrodes.

This is called water line corrosion.

Examples of differential aeration

corrosion

Pitting

or localized corrosion

Crevice corrosion

Pipeline corrosion

Corrosion on wire fence

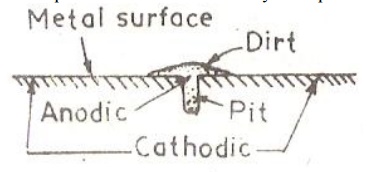

(i) Pitting Corrosion

It is the

localized attack resulting in the formation of a hole due to corrosion. Example

: Metal area covered by a drop of water, sand, dirt etc.

The area

covered by the drop or dirt acts as anode and corrodes. The uncovered area

exposed to air or O2 acts as cathode. The rate of corrosion is more if the

cathodic area is larger and anodic area is smaller. Thus more material is

removed from the same area and a pit is formed.

At anode

: Iron is oxidized to Fe+2

Fe → Fe2+

+ 2e-

At

cathode : O2 is reduced to OH-. ½ O2 + H2O + 2e- → 2OH Overall reaction :

Fe2+ +

OH-→ Fe(OH)

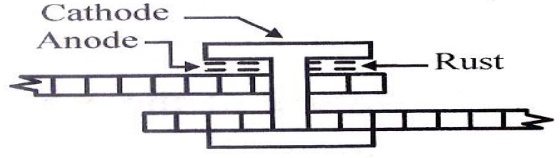

(ii) Crevice Corrosion

Let a

crevice or crack between two different metallic objects be in contact

with a

liquid. The crevice acts like anode due to less oxygen availability and

corrodes. The exposed area acts as cathode.

(e.g.)

rivets, joints.

(iii) Pipeline Corrosion

Buried

pipelines or cables passing from one type of soil (clay, less aerated) to

another type (sand, more aerated) get corroded due to differential aeration.

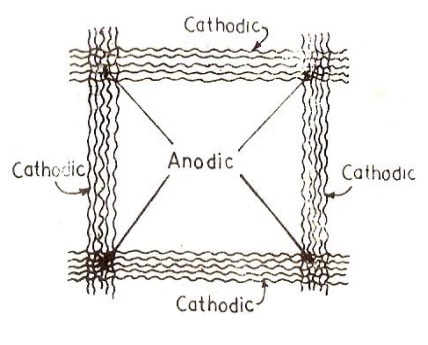

(iv) Corrosion on wire fence

In a wire

fence, the wires at the crossings are less aerated than the rest of the

fence. So

corrosion takes place at the wire crossings, which become anodic.

3

Factors

influencing corrosion

3.1 Nature of the metal

(i) Position in emf series

Metals

above hydrogen in the electrochemical series corrode easily because they have

negative reduction potential. When two metals are in contact, the more active metal

with a higher negative potential corrodes.

(ii) Areas of anode and cathode

Corrosion

will be severe if the anodic area is smaller and cathodic area is larger. The

larger cathodic area demands more electrons. So the anodic area corrodes

faster.

(iii) Purity

100% pure

metal will not corrode. (e.g.) Pure Zn does not corrode. If the metal has trace

amount of impurity, it corrodes. (e.g.) Zinc metal with iron or copper impurity

forms an electrochemical cell. The base metal Zn acts as anode and corrodes.

(iv) Over Voltage

Corrosion

rate is inversely proportional to the over voltage of the metal in a corrosive

surroundings. (e.g.) The hydrogen over voltage of Zn in 1M H2SO4 is 0.7V. So

the rate of corrosion is low. But when some Cu impurity is present, the over

voltage is reduced and corrosion rate increases.

(v) Nature of the Film

Nature of

film formed on the metal surface determines extent of corrosion.(e.g.) In the

case of alkali and alkaline earth metals, the oxide film formed is porous .The

corrosion continues. In the case of heavy metals, the oxide film is non-porous.

The film acts as a protective layer.

(vi) Nature of corrosion product

If the

corrosion product is soluble in the corroding medium, corrosion rate is faster.

Similarly if the corrosion product is volatile (e.g. MoO3), corrosion will be

more.

3.2 Nature of Environment

(i) Temperature

Increase

of temperature increases corrosion rate because the rate of diffusion of ions

increases.

(ii) Humidity

Rate of

corrosion is more, if humidity of environment is high. Moisture acts as solvent

for O2, CO2 etc, to produce electrolyte necessary for formation of corrosion

cell.

(iii) Corrosive gases

Acidic

gases like CO2, SO2, H2S etc, produce electrolytes and increase corrosion.

(iv) Presence of suspended

particles

Particles

like NaCl, (NH4)2SO4 along with moisture are powerful electrolytes and increase

rate of corrosion.

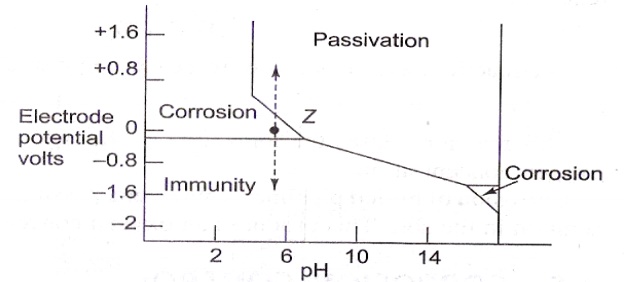

(v) Effect of pH

Generally

in alkaline medium, the rate of corrosion is less compared to acidic medium.

The

effect of pH on the corrosion of iron in water is shown in the Pourbaix diagram

as indicated in the figure.

The

figure shows zones of corrosion, immunity and passivity. Z is the point at

which pH=7 and corresponding electrode potential is E= -0.2V. This is in the

corrosion zone. So iron rusts under these conditions.

The rate

of corrosion can be altered by shifting the point Z to different regions.

If the

potential is changed to -0.8V by applying external current, iron becomes immune

to corrosion.

If the potential applied is positive, iron becomes

passive.

If the pH is increased to more than 7, corrosion

rate decreases.

If the pH is reduced to less than 7, rate of

corrosion increases

4 CORROSION CONTROL

The rate

of corrosion can be controlled by modifying the metal or environment. Some

control methods are

proper selection of metals

Use of pure metals

Use of metal alloys

Cathodic protection

Sacrificial anode protection

Impressed

current cathodic protection 5) Changing the environment

6) Use of

inhibitors

Anodic inhibitors

Cathodic inhibitors

7)

Applying protective coatings

1) Proper selection of metals

Noble

metals are used in ornaments and in surgical instruments, because they do not

corrode. Contact of dissimilar metals far away from each other in

electrochemical series should be avoided.

2) By using pure metals

Pure

metals have high corrosion resistance. Even a trace of impurity will lead to

corrosion, the base metal becoming anode.

3) Use of alloys

Use of

metal alloys is a good method of protection against corrosion. (e.g.) Stainless

steel containing chromium forms a coherent oxide film which protects steel

against further attack

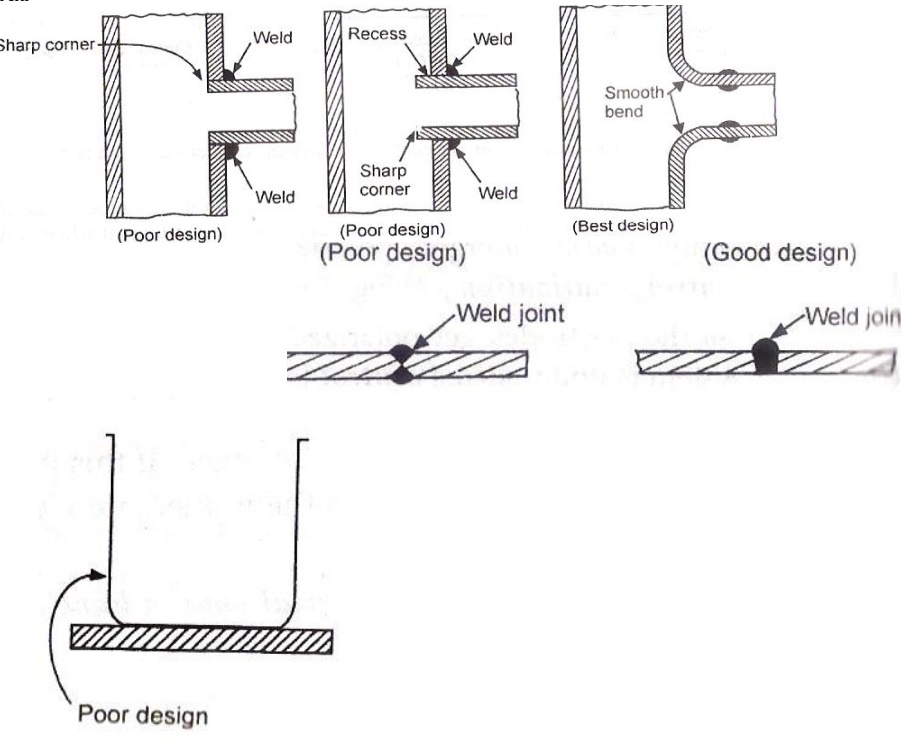

4.1 Proper designing

Complicated

designs with more angles, sharp edges and corners should be avoided.

Direct

contact of dissimilar metals lead to galvanic corrosion. So insulating material

between the two metals should be inserted.

Smaller area for cathode and larger area for anode

must be provided.

Tanks and containers should be designed such that

the liquid should be drained off completely.

Crevices should be avoided or they should be filled

using fillers.

Bendings should be smooth.

Annealing

minimizes corrosion.

5) Cathodic Protection

The metal

to be protected is made to act like a cathode. This is achieved in two ways.

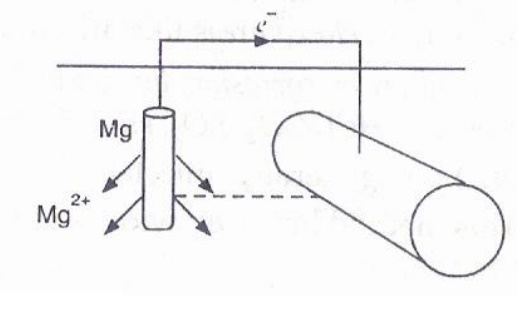

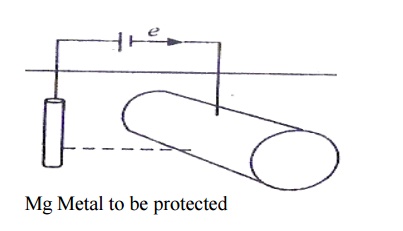

a) Sacrificial anodic protection

Here the

metal to be protected is made cathode by connecting it to a more active metal

(anodic metal) called sacrificial anode. Only the more active metal will

a) Sacrificial anodic protection

Here the

metal to be protected is made cathode by connecting it to a more active metal

(anodic metal) called sacrificial anode. Only the more active metal will be

corroded, protecting the parent metal. Since the anodic metal is sacrificed,

the method is called sacrificial anodic protection. Mg, Zn are used as

sacrificial anodes. Metal to be protected

Applications

Protection

of buried pipelines, cables

Protection of ships and boats

Calcium metal is used to minimize engine corrosion

Magnesium

sheets are inserted into domestic water boilers to prevent rust formation.

b) Impressed current cathodic

protection method

Here an

impressed current is applied in an opposite direction to annul the corrosion

current. Thus the corroding metal is converted to cathode from anode.The

negative terminal of battery is connected to the metal to be protected. The

positive terminal is connected to an inert electrode like graphite. The anode

is buried in a „back-fill‟ (containing a mixture of gypsum, coke breeze and

sodium sulphate) to increase electrical contact.

Mg Metal

to be protected

APPLICATION

Protection

of tanks, transmission line towers, underground water pipes, oil pipe line,

ships etc.

Limitations

It is

costly

It fails when current is switched off.

Corrosion inhibitors

A

corrosion inhibitor is a substance that reduces corrosion, when added to the

corrosive environment. There are three types of inhibitors.

Anodic

inhibitors - chromate, nitrate

Cathodic inhibitors - amines

Vapour phase inhibitors - benzonitrile.

Anodic

inhibitors

(e.g.)

chromate, nitrate, phosphates, tungstate.

The

inhibitors form insoluble compound with the newly produced metal ions and

prevent corrosion. This compound is adsorbed on the metal surface to form a

passive film. Anodic inhibitors are used to repair

i) the

crack of oxide film on metal surface

pitting corrosion

porous oxide film on metal surface

Cathodic

inhibitors

There are

two types depending on the nature of cathodic reaction in an electrochemical

reaction.

a) In acidic solution

Example :

amines, thiourea, mercaptans act as inhibitors. Here evolution of H2 is the

cathodic reaction.

2 H+ +

2e- → H2

The

corrosion is controlled by slowing down the diffusion of H+ ions to cathode by

addition of the inhibitor which is adsorbed on the metal surface.

b) In neutral solution

Example :

hydrazine, sodium sulphite act as inhibitors. Here OH- ions are formed at

cathode. H2O + ½ O2 + 2e- → 2 OH

Corrosion

is controlled by eliminating O2 from the corroding medium by adding Na2SO3. The

OH- ions can be eliminated by salts of Mg, Zn etc.

iii) Vapour phase inhibitors

(e.g.)

benzotriazole, dicyclohexyl ammonium chromate act as inhibitors. These organic

inhibitors readily vapourise and form a protective layer on the metal surface.

4.2 Control of corrosion by

modifying the environment:

There are

five methods

1. Deaeration :

Presence

of oxygen increases corrosion rate. Deaeration involves removal of dissolved

oxygen by increasing the temperature together with the mechanicalagitation.

This also removes dissolved oxygen.

2. Deactivation:

It is the

removal of dissolved oxygen by adding chemicals in aqueous solution.

(E.g.)

2Na2SO3 + O2 → 2Na2SO4

3. Dehumidification:

It is the

removal of moisture from the air by reducing the relative humidity of the

surrounding air. It can be achieved by adding silica gel or alumina which

absorbs

moisture.

4. Alkaline neutralization:

The

acidic nature of the corrosive environment is due to the presence of HCl, SO2,

CO2 etc. They are neutralized with alkali spray. E.g. NaOH lime etc.

5. Using corrosion inhibitors :

A

corrosion inhibitor is a substance that reduces the corrosion of a metal when

added to corrosive environment

Applications

To

prevent corrosion in closed space, storage containers, sophisticated equipment

etc.

PROTECTIVE COATINGS

Metal

surface is covered by a protective coating to prevent corrosion. The coating

acts as a physical barrier between the metal surface and the environment. The

coating gives a decorative appeal and also imparts hardness, oxidation

resistance and thermal insulation to the surface. The main types of coating

are:

Metallic coating

Chemical conversion coating

Organic coating

Non-metallic coating

5 PAINT

Paint is

a mechanical dispersion of one or more fine pigments in a medium (thinner +

vehicle). When a paint is applied to metal surface, the thinner evaporates. The

vehicle undergoes slow oxidation to form a pigmented film.

5.1 Requirements or requisites of

a good paint

A good

paint should,

have good

covering power

spread easily on the surface

not crack on drying

adhere well to the surface

give a glossy film

be corrosion and water resistant

have stable colour

5.2Constituents of Paint

Pigment

Vehicle Thinner Drier Filler Plasticizer

Anti

skinning agent

1. Pigment

It is a

solid that gives colour to the paint.

Functions:

1. To

give colour and opacity to the film.

2. To

provide strength to the film.

3. To

protect film by reflecting U.V. rays.

4. To

provide resistance to abrasion and weather.

Example:

White

pigment - White lead, TiO2

Blue

pigment - Prussion blue

Green

pigment - Chromium oxide

Red

pigment - Red lead, Fe3O4

2. Vehicle (or) Drying Oil

It is the

film-forming liquid. It holds the ingredients of the paint. It is a nonvolatile

high molecular weight fatty acid of vegetable or animal.

Function

1. To

hold the pigment on the surface.

2. To

form a protective layer by oxidation and polymerization. 3. To impart water repellency, toughness and

durability of film. 4. To improve adhesion of film.

Example

Lin seed

oil, Castor oil.

3. Thinner

It is the

volatile portion of paint. It is added to reduce the viscosity of the paintfor

easy application on the surface. It easily evaporates after paint is applied.

Functions

1. To

reduce viscosity of paint.

2. To

dissolve vehicle and other additives.

3. To

suspend the pigments.

4. To

increase elasticity of film.

5. To

increase penetration of vehicle.

6. To

improve drying of film.

Example

Turpentine,

Dipentine, Xylol.

4. Drier

It is a

substance used to speed up drying of the paint.

Functions

1. To act

as oxygen carrier or catalys.

2.To

provide oxygen essential for oxidation and polymerization of drying oil.

Example

Metallic

soap, linoleate and resinate of Co, Mn etc.

5. Extender or Filler

These are

white pigments that form bulk of the paint.

Functions

1. To

reduce cost of paint

2. To

prevent shrinkage and cracking of film

3. To

modify shades of pigment

4. To

retard settling of pigments in paint.

Example

Talc

gypsum, china-day.

6. Plasticizer

It is

added to the paint to provide elasticity to the film and prevent its cracking.

Example

Triphenyl

phosphate, Tricresyl phosphate

7. Antiskinning agent

It is a

chemical added to the paint to prevent gelling and peeling of the paint.

Example

Polyhydroxy

phenols.

Pigment Volume Concentration

(P.V.C.)

The

P.V.C. of a paint is calculated using the equation. P.V.C. =

Volume of

pigment in the paint =Volume of pigment in the paint + Volume of non-volatile

vehicle in the paint

If P.V.C.

is high, durability, adhesion and consistency of the paint will be low.

Failure of Paints

A paint

may fail due to any one of the following reasons:

Chalking : It is the gradual powdering of

the paint film on the painted surface. This happens due to improper dispersion of pigment in vehicle.

Cracking

: A paint

film cracks due to unequal expansion or contraction of paint coats.

Evasion : This is very

quick chalking.

iv) Blistering : It is due to improper

surface exposure of paint to strong sunshine.

6 Metallic Coating

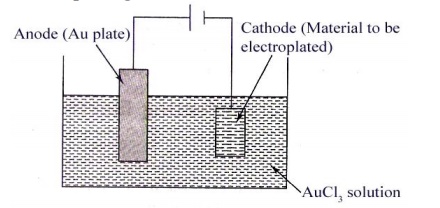

6.1 Electroplating or

Electro-deposition

It is the

deposition of coat metal on the base metal by passing direct current through an

electrolytic solution of a soluble salt of the coat metal. The base metal to be

electroplated acts as cathode. The coat metal or an inert electrode forms

anode. The electrolyte is a soluble salt of coat metal.

Objectives or uses or

applications of Electroplating:

To

enhance resistance to corrosion of base metals.

To give a decorative appearance.

To enhance resistance to chemical attack.

To improve hardness and wearing resistance.

To obtain polished surface.

Theory

If the

coating metal itself forms the anode, the concentration of electrolyte bath

does not change during electrolysis. The metal ions deposited on the cathode

are replenished continuously by dissolution of the anode.

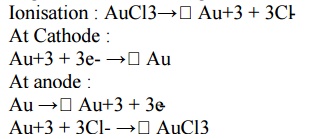

Example

Electroplating of Gold

The

object to be gold plated is treated with organic solvent like acetone, CCl

to remove

grease, oil etc. It is then washed with dil H2SO4 to remove scales, oxides etc.

The cleaned object is made cathode of electrolytic cell. Anode is a gold plate.

AuCl3 solution is the electrolyte. When current is passed into the solution,

gold ions migrate to the cathode, get reduced and deposit on the object.

Conditions

Temperature

: 600C

Current density : 1 to 10 mA/cm

Low metal ion concentration

Buffer solution to maintain pH.

Applications or Uses or

Objectives

To give a

decorative appearance.

Electrical and electronic applications

To get a thin coating of gold on cheap jewellery

To achieve oxidation resistance, corrosion

resistance etc.

6.2 Electroless Plating

It is the

deposition of a noble metal (from its salt solution) on a catalytically active

metal surface using a reducing agent without use of electric current.The

reducing agent reduces the metal ions. The metal atoms get deposited over the

surface to give a thin uniform coating.

Metal

ions + reducing agent metal (deposited)

+ oxidation product

Example

Electroless nickel plating

The

various steps are:

Step I : Pretreatment and

activation of the surface:

The

surface to be plated is degreased by using organic solvents or alkali and then

accompanied by acid treatment.

The

surface of stainless steel is activated by dipping in hot solution of 50%

H2SO4.

Mg alloy surface is activated by giving a thin

coating of zinc and copper overit.

Al, Cu, Fe, brass etc, do not require activation.

Plastic, glass etc, are activated by dipping in a

solution of SnCl2/HCl and then

in PdCl2

solution. On drying a thin layer of palladium is formed on the surface.

Step II : Preparation of plating

bath:

The

plating bath consists of:

Coating

Metal : A solution of NiCl2 20g/lit.

Reducing agent : Sodium hypophosphite 20g/lit.

Exaltant to accelerate coating rate and complexing

agent : Sodium succinate 15g/lit.

Buffer to maintain pH at 4.5 : Sodium acetate

10g/lit.

Temperature 93oC

The

pretreated object is immersed in the plating bath for required time. The

following reactions occur and nickel is coated on the object.

Cathode :

Ni2+ + 2e- → Ni

Anode :

H2PO2- + H2O → H2PO2- + 2H+ + 2e

Overall

Reaction : Ni2+ + H2PO2- + H2O → Ni + H2PO3- + 2H+

Uses of Nickel Plating

For

decorative coating of jewellery, decorative items and automobile spares

For coating of polymers for decorative purpose.

For electronic appliances.

Advantages of electroless plating

over electro plating

Electricity

is not necessary

Complicated parts are uniformly coated

Plastics, glass etc, are easily coated

Good mechanical, chemical and magnetic properties

are obtained.

Differences between

Electroplating and Electroless plating:

Electroplating Electroless

Plating

It is done by passing current. It is done by auto

catalytic redox reaction.

Separate anode is required. Catalytic surface of

the object acts as anode.

Anode reaction: M → Mn+ + ne- Anode reaction : R →

O + ne-

Cathode reaction: Mn+ + ne-→ M Cathode reaction: Mn+ + ne- → M

Irregular objects are not satisfactorily plated All

objects are satisfactorily plated.

Object to be coated forms the cathode .Object to be

coated forms catalytically active surface.

It is carried out on conducting materials.It is

carried out even on insulators.

Related Topics