Chapter: Civil : Strength of Materials : Columns

Important Questions and Answers: Civil - Strength of Materials - Columns

Strength

of Materials - Columns

1.Define: Column and strut.

A column is a long vertical slender

bar or vertical member, subjected to an axial compressive load and fixed

rigidly at both ends.

A strut is a slender bar or a member

in any position other than vertical, subjected to a compressive load and fixed

rigidly or hinged or pin jointed at one or both the ends.

2.

What are the types of column

failure?

1.

Crushing failure:

The column will reach a stage, when

it will be subjected to the ultimate crushing stress, beyond this the column

will fail by crushing The load corresponding to the crushing stress is called

crushing load. This type of failure occurs in short column.

2. Buckling failure:

This kind of failure is due to

lateral deflection of the column. The load at which the column just buckles is

called buckling load or crippling load or critical load. This type of failure

occurs in long column.

3. What is slenderness ratio ( buckling factor)? What is its

relevance in column?

It is the ratio of effective length

of column to the least radius of gyration of the cross sectional ends of the

column.

Slenderness ratio = l eff / r

l eff = effective length of column r

= least radius of gyration

Slenderness ratio is used to

differentiate the type of column. Strength of the column depends upon the

slenderness ratio, it is increased the compressive strength of the column

decrease as the tendency to buckle is increased.

4. What are the factors affect the strength column?

1.Slenderness ratio

Strength of the column depends upon

the slenderness ratio, it is increased the compressive strength of the column

decrease as the tendency to buckle is increased.

2.

End conditions: Strength of the column depends upon the end

conditions also.

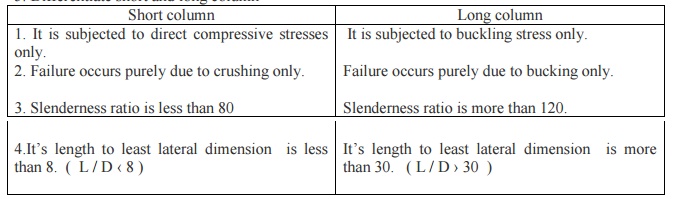

5.Differentiate

short and long column

6.What are the

assumptions followed in Euler's equation?

1. The material of

the column is homogeneous, isotropic and elastic.

2. The section of

the column is uniform throughout.

3. The column is

initially straight and load axially.

4. The effect of the

direct axial stress is neglected.

5. The column fails

by buckling only.

7. What are the

limitations of the Euler's formula?

1. It is not valid

for mild steel column. The slenderness ratio of mild steel column is less than 80.

2. It does not take

the direct stress. But in excess of load it can withstand under direct

compression only.

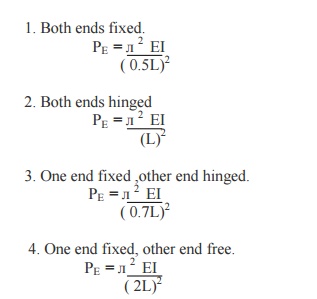

8. Write the

Euler's formula for different end conditions.

1.

Both ends fixed.

2.

Both ends hinged

3.

One end fixed ,other end

4.

One end fixed, other end

L = Length of the column

9. Define: Equivalent

length of the column.

The distance between adjacent points

of inflection is called equivalent length of the column. A point of inflection

is found at every column end, that is free to rotate and every point where

there is a change of the axis. ie, there is no moment in the inflection points.

(Or)

The equivalent length of the given

column with given end conditions, is the length of an equivalent column of the

same material and cross section with hinged ends , and having the value of the

crippling load equal to that of the given column.

10. What are the uses of south well plot? (column curve).

The relation between the buckling

load and slenderness ratio of various column is known as south well plot.

The south well plot is clearly shows

the decreases in buckling load increases in slenderness ratio.

It gives the exact value of

slenderness ratio of column subjected to a particular amount of buckling load.

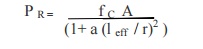

11. Give Rakine's formula

and its advantages.

where,

P R = Rakine's critical load

f C =

yield stress

A = cross sectional area

a = Rakine's constant

= effective length

r = radius of gyration

In case of short column or strut,

Eul er's load will be very large. Therefore, Euler's formula is not valid for

short column. To avoid this limitation, Rankine's formula is designed. The

Rankine's formula is applicable for both long and short column.

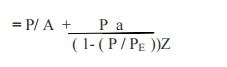

12. Write Euler's formula for maximum stress for a initially bent column?

? max = P /A + ( M max / Z )

Where, P = axial load

A = cross section area PE

= Euler's load

a = constant

Z = section modulus

13.

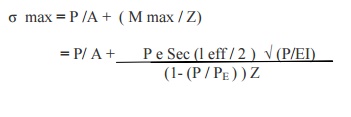

Write Euler's formula for

maximum stress for a eccentrically loaded column?

Where, P = axial load

A = cross section area PE

= Euler's load

e = eccentricity

Z = section modulus EI = flexural

rigidity

14. What is beam column? Give examples.

Column having transverse load in

addition to the axial compressive load are termed as beam column.

Eg : Engine shaft, Wing of an

aircraft.

15. Define buckling factor and buckling load.

Buckling factor : It is the ratio between the equivalent length of the column to

the minimum radius of gyration.

Buckling load : The maximum limiting load at which the column tends to have lateral

displacement or tends to buckle is called buckling or crippling load. The

buckling takes place about the axis having minimum radius of gyration, or least

moment of inertia.

16. Define safe load.

It is the load to which a column is

actually subjected to and is well below the buckling load. It is obtained by

dividing the buckling load by a suitable factor of safety (F.O.S).

Safe load =

Buckling load / Factor of safety

17. Write the general expressions

for the maximum bending moment, if the deflection curve equation is given.

BM = - EI ( d 2y / dx 2 )

18. Define thick cylinders.

Thick cylinders are the cylindrical

vessels, containing fluid under pressure and whose wall thickness is not small.

(t ³d/20)

19.

State the assumptions made

in Lame's theory.

i)

The material is homogeneous and

isotropic.

ii)

Plane sections perpendicular to the

longitudinal axis of the cylinder remain plane after the application of

internal pressure.

iii)

The material is stressed within the

elastic limit.

iv)

All the fibres of the material are

to expand or contract independently without being constrained by the adjacent

fibres.

20.

Write Lame's equation to

find out stesses in a thick cylinder.

Radial stress = sr = b - a r2

Circumferential or hoop stress = sc = b + a r2

21. State the variation of hoop stress in a thick cylinder.

The hoop stress is maximum at the

inner circumference and minimum at the outer circumference of a thick cylinder.

22. How can you reduce hoop stress in a thick cylinder.

The hoop stress in

thick cylinders are reduced by shrinking one cylinder over another cylinder.