Chapter: Civil : Strength of Materials : State of Stress in Three Dimensions

Strength of Materials- State of Stress in Three Dimensions

STATE OF STRESS IN THREE DIMENSIONS

1 STRESS

When a certain system of external forces act

on a body then the body offers resistance to

these forces. This internal resistance offered by the body per unit area

is called the stress induced in the

body.

2 PRINCIPAL PLANES

The plane in which the shear stress is zero is

called principal planes. The plane which is

independent of shear stress is known as principal plane.

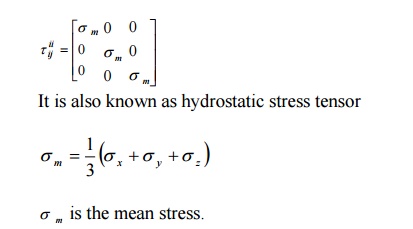

3 SPHERICAL TENSOR

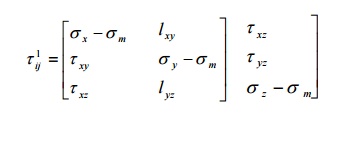

4 DEVIATOR

STRESS TENSOR

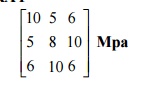

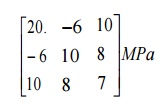

5 THE STRESS COMPONENTS AT A POINT ARE

GIVEN BY THE FOLLOWING ARRAY

Calculate the principal stress and principal

planes.

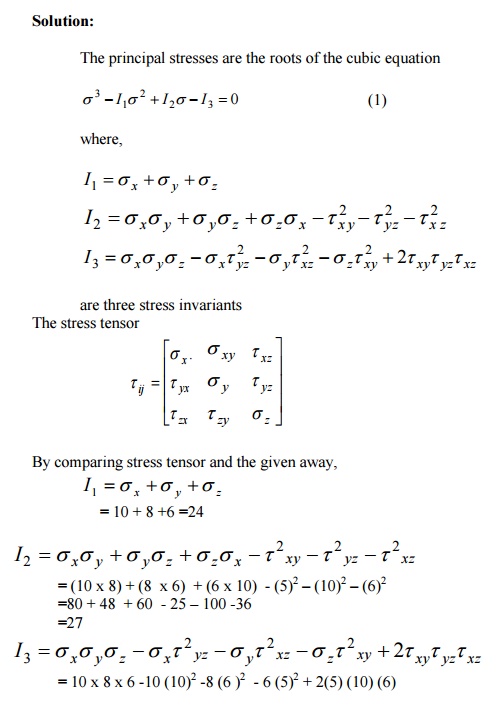

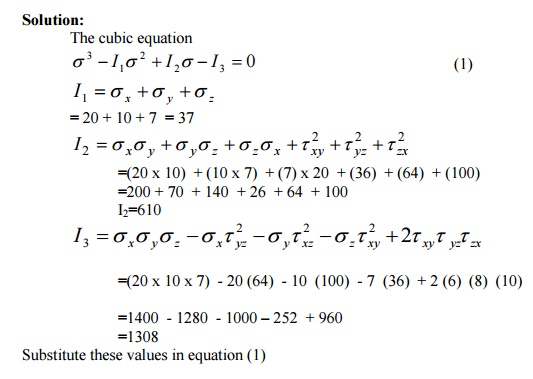

Solution:

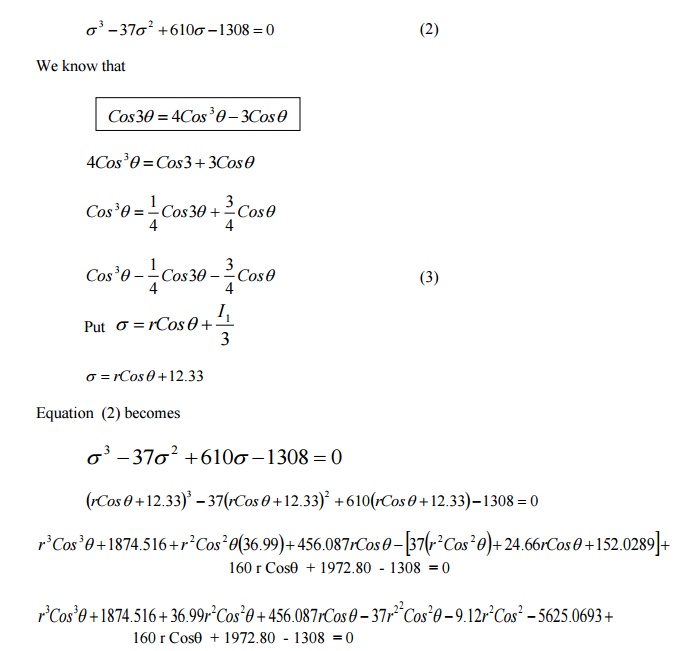

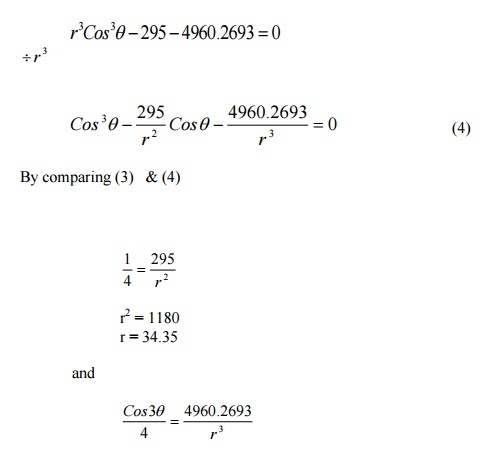

The principal

stresses are the roots of the cubic equation

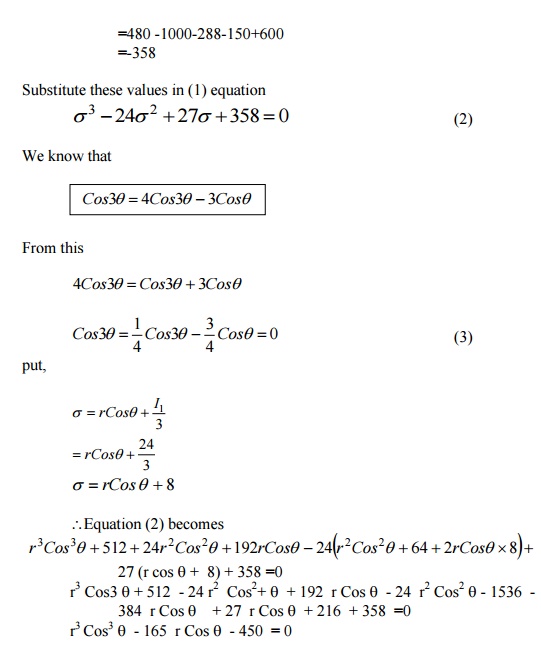

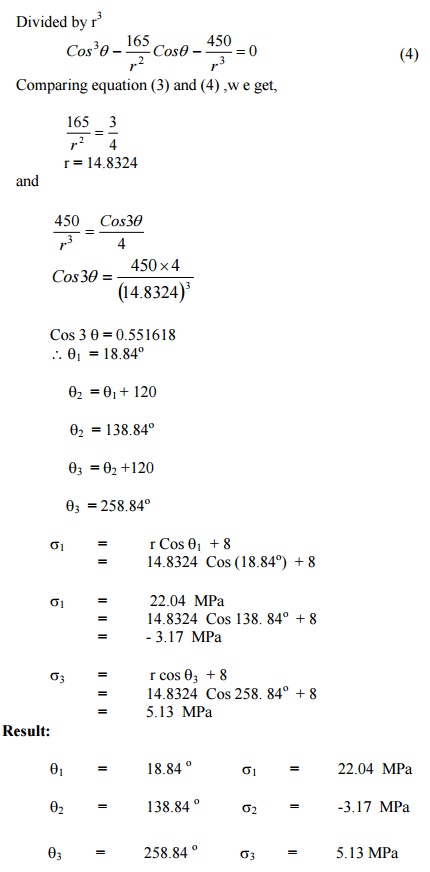

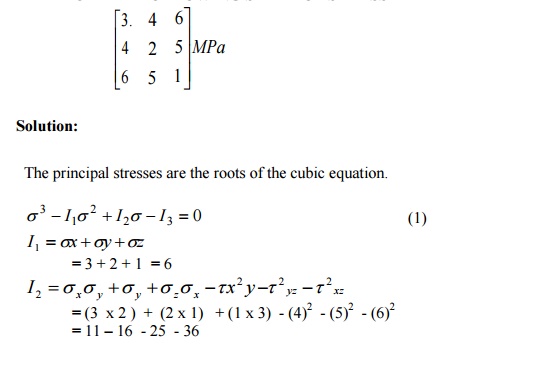

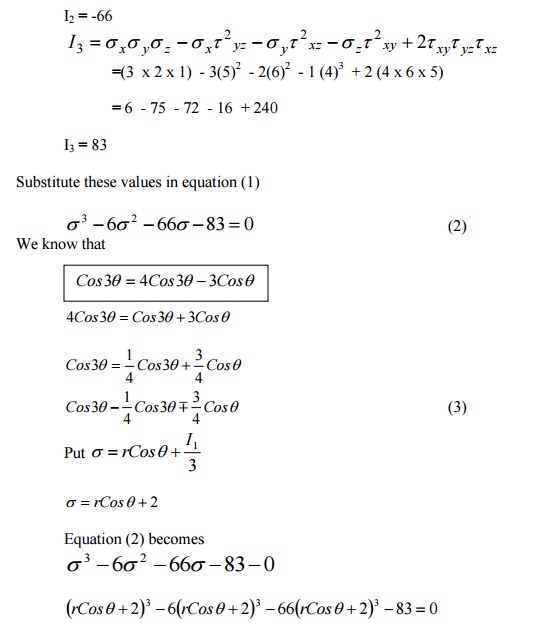

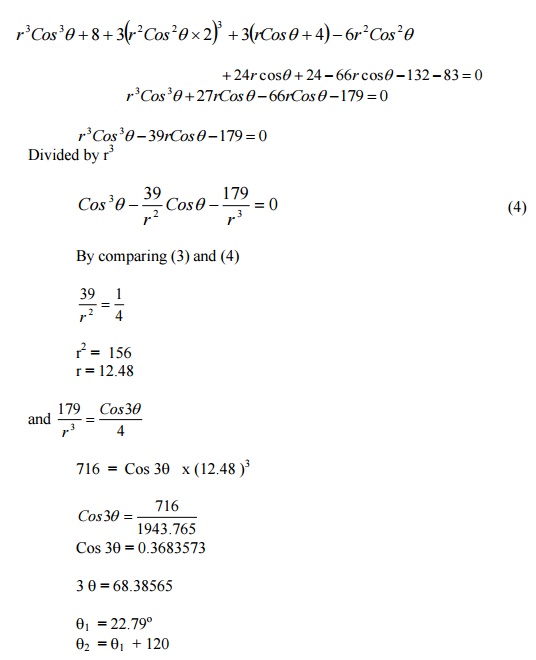

6 OBTAIN THE PRINCIPAL STRESSES AND THE

RELATED DIRECTION COSINES FOR THE

FOLLOWING STATE OF STRESS

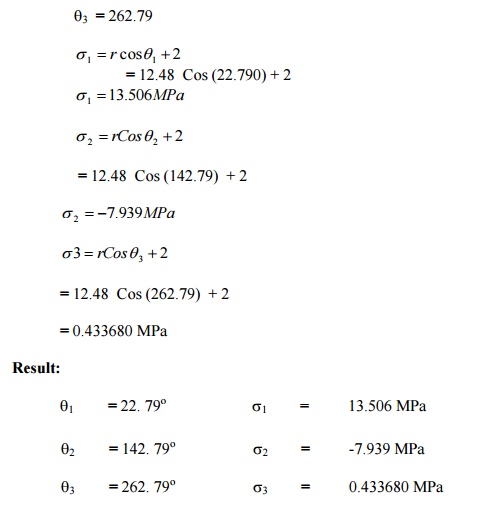

THE STATE OF STRESS AT A POINT IS GIVEN BY

Determine the principal stresses and principal

direction.

Solution:

9 EXPLAIN THE ENERGY OF

DISTORTION ( SHEAR STRAIN ENERGY ) AND DILATATION

The strain

energy can be split up on the following two strain energies.

i.

Strain energy of distortion (shear strain

energy)

ii.

Strain energy of Dilatation (Strain energy of

uniform compression (or)) tension (or)

volumetric strain energy )

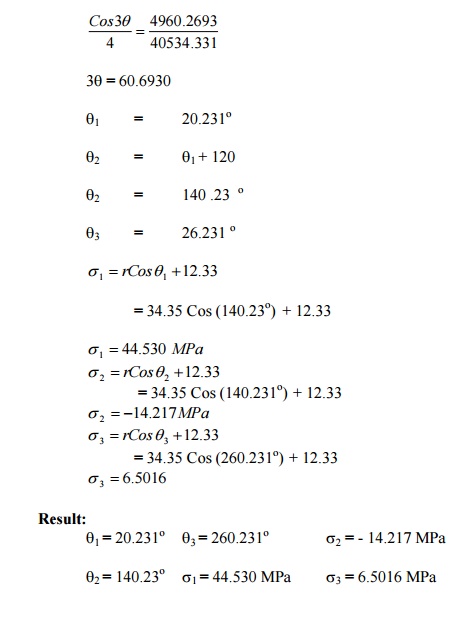

Let e1

e2 an d e3 be the

principal strain in the directions of principal stresses s1, s2 and s3.

. This means that if sum of the three principal

stress is zero there is no volumetric

change, but only the distortion occurs.

From the

above discussion,

1.

When the sum of three principal stresses

is zero, there is no volumetric change but only the distortion occurs.

2.

When the three principal stresses are equal to

one another there is no distortion but

only volumetric change occurs.

Note:

In the above six theories,

set , sec = Tensile

stress at the elastic limit in simple tension and compression;

s1, s2, s3 = Principal stresses in any complex system

(such that e1 > e2 > e3 )

It may be assumed that the loading is gradual

(or) static (and there is no cyclic (or)

impact load.)

10 STATE THE PRINCIPAL THEORIES OF

FAILURE

1.

Maximum principal stress theory

2.

Maximum shear stress (or) stress difference

theory

3.

Strain energy theory

4.

Shear strain energy theory

5.

Maximum principal strain theory

6.

Mohr?s

Theory

11 LIMITATIONS OF

MAXIMUM PRINCIPAL STRESS THEORY

1.

On

a mild steel

specimen when spiel

tension test is

carried out sliding

occurs approximately 45o

to the axis of the specimen; this shows that the failure in this case is due to maximum shear stress rather than the

direct tensile stress.

2.

It has been found that a material which is

even though weak in simple compression yet

can sustain hydrostatic pressure for in excess of the elastic limit in

simple compression.

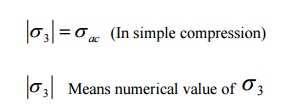

12 MAXIMUM PRINCIPAL

STRESS THEORY

According to this theory failure will occur

when the maximum principle tensile stress

(s1)

in the complex system reaches the value of the maximum stress at the elastic

limit (set)

in the simple tension.

13

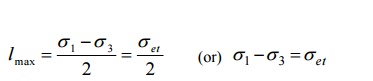

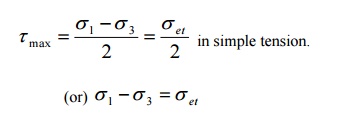

MAXIMUM SHEAR STRESS THEORY

This theory implies that failure will

occur when the maximum shear stress in

the complex system reaches the value of the maximum shear stress in simple

tension at elastic limit (i.e)

14 LIMITATIONS OF MAXIMUM SHEAR

STRESS THEORY

i.

The theory does not give accurate results for

the state of stress of pure shear in which

the maximum amount of shear is developed (i.e) Torsion test.

ii.

The theory does not give us close results as

found by experiments on ductile

materials. However, it gives safe results.

15 SHEAR STRAIN ENERGY

THEORY

According to this theory the elastic failure

occurs where the shear strain energy per unit

volume in the stressed material reaches a value equal to the shear

strain energy per unit volume at the

elastic limit point in the simple tension test.

16

LIMITATIONS OF DISTORTION ENERGY THEORY

1. The theory does to

agree the experiment results for the material for which sat is quite different etc.

2.

This theory is regarded as one to which

conform most of the ductile material under

the action of various types of loading.

17 MAXIMUM PRINCIPAL STRAIN THEORY

The theory states that the failure of a

material occurs when the principal tensile strain in the material reaches the strain at the

elastic limit in simple tension (or) when the min minimum principal strain (ie ) maximum principal

compressive strain reaches the elastic limit in simple compression.

18 LIMITATIONS IN

MAXIMUM PRINCIPAL STRAIN THEORY

i.

The theory overestimates the behaviour of

ductile materials.

ii.

The theory does no fit well with the

experimental results except for brittle materials

for biaxial tension.

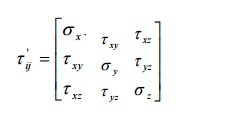

19 STRESS TENSOR IN CARTESIAN COMPONENTS

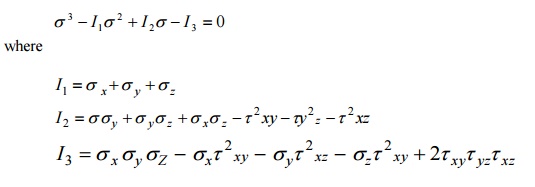

20 THREE STRESS INVARIANTS

The principal

stresses are the roots of the cubic equation,

21 TWO TYPES OF STRAIN ENERGY

i.

Strain energy of distortion (shear strain

energy)

ii.

Strain energy of dilatation.

MOHR'S THEORY

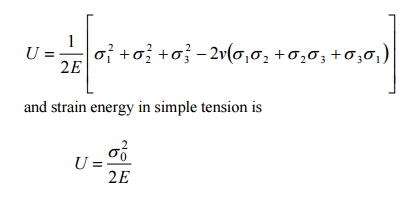

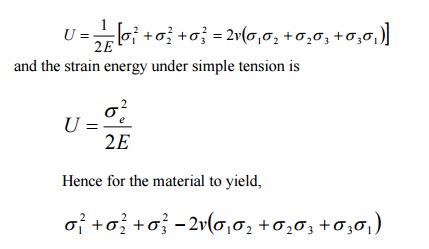

Total Strain Energy Theory

The total strain energy of deformation is

given by

22 EXPLAIN THE MAXIMUM

PRINCIPAL STRESS THEORY:

-

This is the simplest and the oldest theory of

failure

-

According to this theory failure will occur

when the maximum principle tensile

stress (?1)

in the complex system reaches the value of the maximum stress at the elastic limit (?et)

in the simple tension (or) the minimum principal stress (that is, the maximum principal compressive stress),

reaches the elastic limit stress (?)

in simple compression.

(ie.) ?1 = ?et (in simple tension)

-

If the maximum principal stress is the design

criterion, the maximum principal stress

must not exceed the working sfor

the material. Hence,

?1 < ?

-

This theory disregards the effect of other

principal stresses and of the shearing stresses

on other plane through the element. For brittle materials which do not

fail by yielding but fail by brittle

fracture, the maximum principal stress theory is considered to be reasonably satisfactory.

This theory

appears to be approximately correct for ordinary cast -irons and brittle metals.

23 THE MAXIMUM PRINCIPAL STRESS THEORY IS

CONTRADICTED IN THE FOLLOWING CASES:

On a mild steel specimen when simple

tension test is carried out sliding occurs approximately 45o to the

axis of the specimen; this shows that the failure in the case is due to maximum

shear stress rather than the direct tensile stress.

2.

It has been found that a material which is

even though weak in simple compression

yet can sustain hydrostatic pressure for in excess of the elastic limit in simple compression.

24 EXPLAIN THE MAXIMUM

SHEAR STRESS (OR) STRESS DIFFERENCE THEORY

-

This theory implies that failure will occur when the maximum shear stress maximum in the complex system reaches the

value of the maximum shear stress in

simple tension at the elastic limit i.e.

In actual

design set in the above equation is replaced by the safe

stress.

-

This theory gives good correlation with results

of experiments on ductile materials. In

the case of two dimensional tensile stress and then the maximum stress difference

calculated to equate it to set.

Limitations of this theory:

i.

The theory does not give accurate results for

the state of stress of pure shear in

which the maximum amount of shear is developed (ie) Torsion test.

ii.

The theory is not applicable in the case where

the state of stress consists of triaxial

tensile stresses of nearly equal magnitude reducing, the shearing stress

to a small magnitude, so that failure

would be by brittle facture rather than by yielding.

iii.

The theory does not give as close results as

found by experiments on ductile

materials. However, it gives safe results.

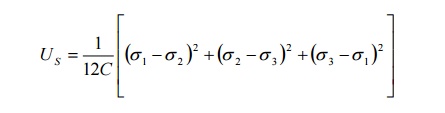

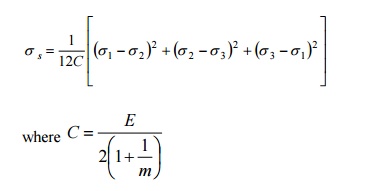

25 EXPLAIN THE SHEAR

STRAIN ENERGY THEORY

This theory is also called 'Distortion-Henky E

Theory'

-

According to this theory the elastic failure occurs where the shear strain

energy per unit volume in the stressed

material reaches a value equal to the shear strain energy per unit volume at the elastic limit

point in the simple tension test.

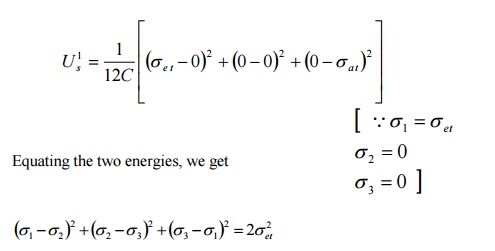

Shear strain energy due to the principal

stresses s1,

s2,

and s3

per unit volume of the stress material.

But for the simple tension test at the elastic

limit point where there is only one principal

stress (ie) set

we have the shear strain energy per unit volume which is given by

The above theory has been found to give best

results for ductile material for which set

=sec

approximately.

Limitations of Distortion energy theory:

1.

Te theory does to agree with the experimental

results for the material for which ?et

is quite different from ?ec.

2. The theory gives ?et =0 for hydrostatic pressure (or) tension, which means that the material will never fail under any hydrostatic pressure (or) tension. When three equal tensions are applied in three principal directions, brittle facture occurs and as such maximum principal stress will give reliable results in this case.

3.

This theory is regarded as one to which

conform most of the ductile material under

the action of various types of loading.

26 EXPLAIN THE MAXIMUM

PRINCIPAL STRAIN THEORY

-

This theory associated with St Venent

-

The theory states that the failure of a

material occurs when the principal tensile

strain in the material reaches the strain at the elastic limit in simple

tension (or) when the minimum principal

strain (ie) maximum principal compressive strain reaches the elastic limit in simple

compression.

Principal strain in the direction of

principal stress ?1,

Limitations:

i.

The theory overestimates the behavior of

ductile materials.

ii.

Te theory does not fit well with the

experimental results except for brittle materials for biaxial tension.

27

EXPLAIN THE STRAIN ENERGY THEORY

The total

stain energy of deformation is given by

The total elastic energy stored in a material

before it reaches the plastic state can have no

significance as a limiting condition, since under high hydrostatic

pressure, large amount of strain energy

ma be stored without causing either fracture (or) permanent deformation.

28 EXPLAIN

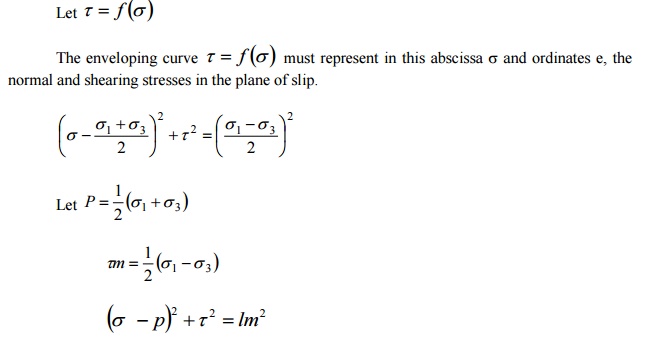

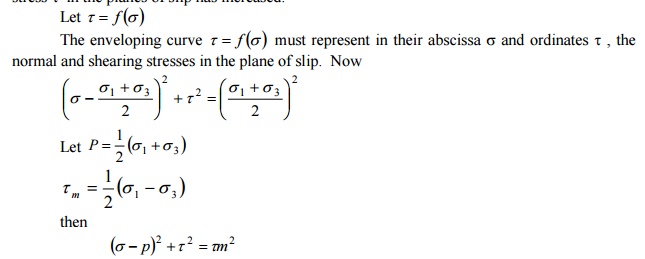

MOHR'S THEORY

A material

may fail either through plastic slip (or) by fracture when either the

shearing stress t in the planes of slip has increased.

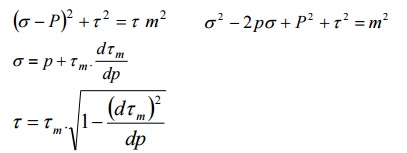

This equation represents the family of

major principal stress circles in parameter form. The equation of this envelope

is obtained by partially differentiating with respect to P

This is to equation of Mohr? principal

stress in parameter form.

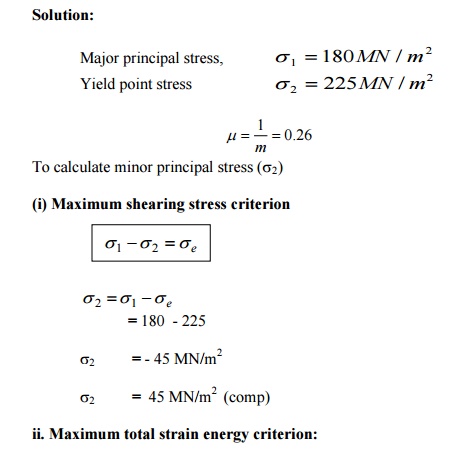

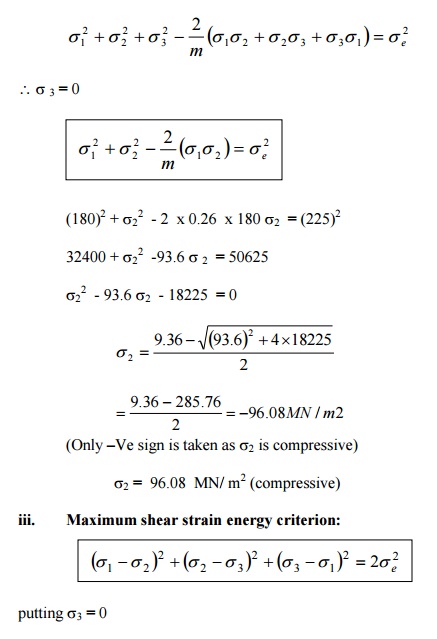

IN A STEEL MEMBER, AT A POINT THE MAJOR

PRINCIPAL STRESS IS 180 MN/M2

AND THE MINOR PRINCIPAL STRESSES IS COMPRESSIVE. IF THE TENSILE YIELD POINT OF THE STEEL IS 225 MN/M2,

FIND THE VALUE OF THE MINOR PRINCIPAL

STRESS AT WHICH YIELDING WILL COMMENCE,

ACCORDING TO EACH OF THE FOLLOWING CRITERIA OF FAILURE.

i.

Maximum shearing stress

ii.

Maximum total strain energy

iii.

Maximum shear strain energy

Take Poisson's ratio

= 0.26

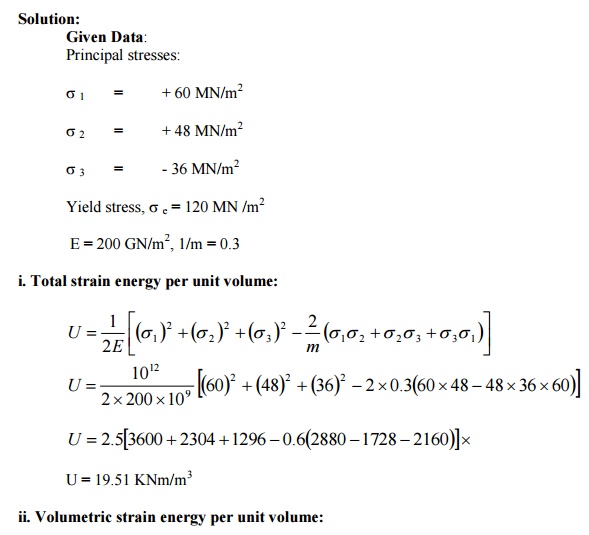

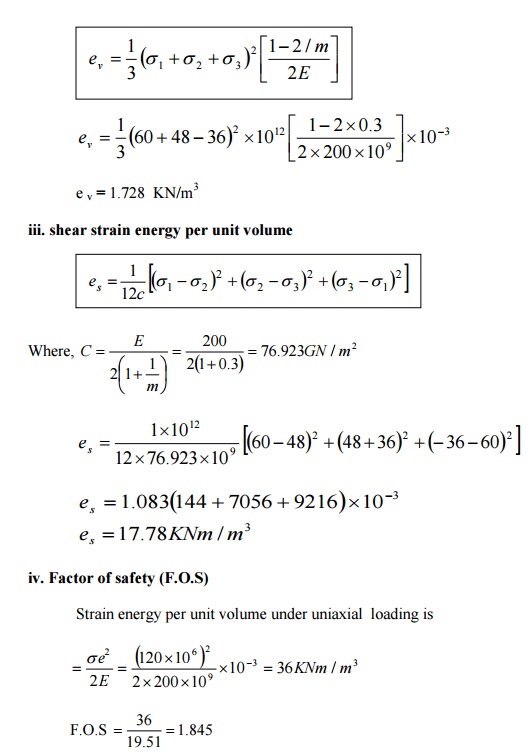

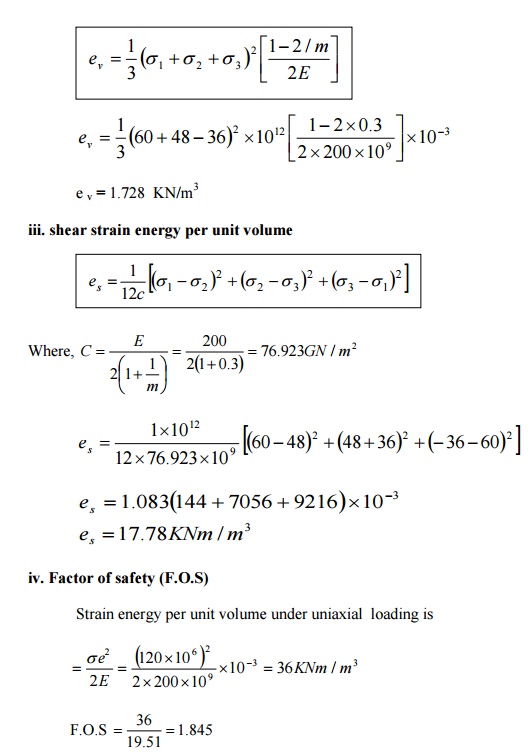

IN A MATERIAL THE PRINCIPAL STRESSES ARE 60

MN/M2, 48 MN/M2 AND - 36

MN/M2. CALCULATE

i.

TOTAL STRAIN ENERGY

ii.

VOLUMETRIC STRAIN ENERGY

iii.

SHEAR STRAIN ENERGY

iv.

FACTOR OF SAFETY ON THE TOTAL STRAIN

ENERGY CRITERIA IF THE MATERIAL YIELDS

AT 120 MN/M2.

TAKE E = 200 GN/M2+ AND 1/M = 0.3

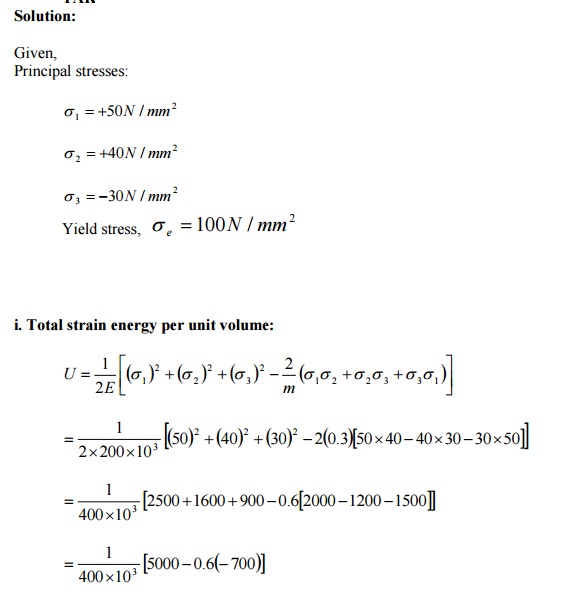

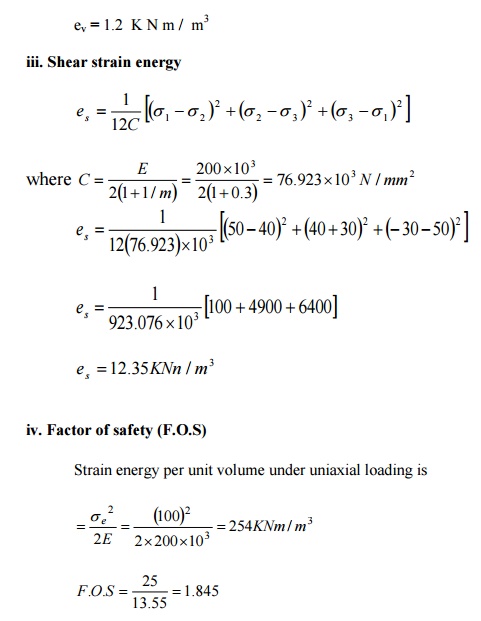

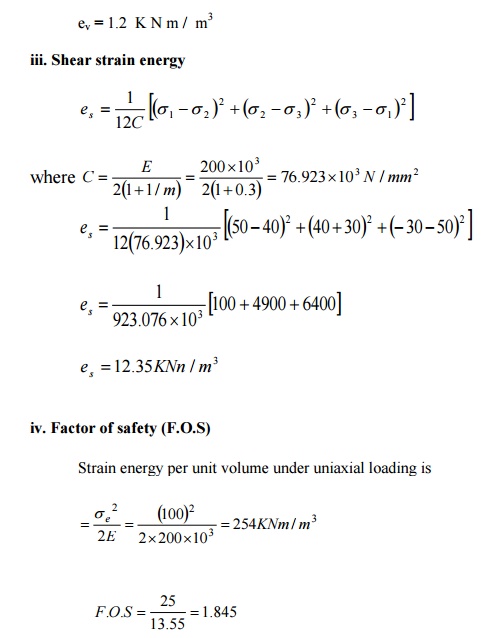

IN A MATERIAL THE PRINCIPAL STRESSES ARE 50

N/MM2, 40 N/MM2 AND - 30 N/MM2, CALCULATE:

i.

TOTAL STRAIN ENERGY

ii.

VOLUMETRIC STRAIN ENERGY

iii.

SHEAR STRAIN ENERGY AND

iv.

FACTOR OF SAFETY ON THE TOTAL STRAIN

ENERGY CRITERION IF THE MATERIAL YIELD

AT 100 N/MM2.

iii.

TAKE E = 200 X 103 N/MM2

AND POISSION RATIO = 0 .28

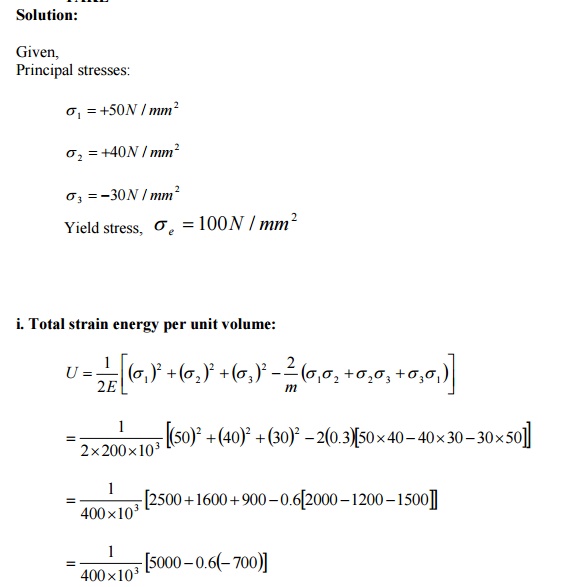

IN A MATERIAL THE PRINCIPAL STRESSES ARE 50

N/MM2, 40 N/MM2 AND - 30

N/MM2, CALCULATE:

v.

TOTAL STRAIN ENERGY

vi.

VOLUMETRIC STRAIN ENERGY

vii.

SHEAR STRAIN ENERGY AND

viii.

FACTOR OF SAFETY ON THE TOTAL STRAIN

ENERGY CRITERION IF THE MATERIAL YIELD

AT 100 N/MM2.

TAKE E = 200 X 103 N/MM2

AND POISSION RATIO = 0 .28

29 SHEAR STRAIN ENERGY

PER UNIT VOLUME

30 THEORIES OF FAILURE

The principal theories are:

1. Maximum principal stress

theory

2. Maximum shear stress (or)

stress difference theory

3. Strain energy theory

4. Shear strain energy theory

5. Maximum principal strain

theory

Related Topics