Chapter: Mechanical : Strength of Materials : Thin Cylinders, Spheres and Thick Cylinders

Important Answers: Thin Cylinders, Spheres and Thick Cylinders

THIN CYLINDERS, SPHERES AND THICK

CYLINDERS

1.

List out the modes of failure in thin cylindrical shell due to an internal

pressure.

i)Circumferential or hoop stress and

ii)Longitudinal

stress

2. What do you mean by principal plane?

The

planes which have no shear stress are known as principal planes.

3. What are assumptions involved in the

analysis of thin cylindrical shells?

The material of the cylinder is homogeneous, isotr

i)The hoop stress distribution in thin cylinder is uniform over the cross

section from inner to outer

surface since the thickness of the cylinder is thin

and

ii)Weight

of fluid and material of the cylinder is not taken into account.

4.What are principal planes and

principal stress one end is fixed and other end is free?

Principal stress: The magnitudes of normal stress,

acting on a principal plane are known as principal stresses. The plane which

have no shear stress are known as principal planes.

5. Define Circumferential and Hoop

stress.

A thin cylinder shell is subjected to an internal

pressure, as a result of internal pressure, the cylinder has tendency to split

up into two troughs is called circumferential stress. The same cylinder shell,

subjected to the same internal pressure, the cylinder also has a tendency to

split in to two ieces is known as Hoop stress.

6. What

is the ?use

of Mohr’s

It

is used to find out the normal, tangential, resultant and principal stresses

and their

planes.

7.What are the planes along which the greatest

shear stresses occurs?

Greatest shear stress occurs at the planes which is

inclined at 45Ëšto

its normal.

8.What

is the radius

of Mohr’s ?

Radius of Mohr’s circle is equal to the maximum

shear stress.

9. In case of equal like principal stresses what is

the diameter of the Mohr’s circle?

In case of equal like principal stresses what is the

diameter of the Mohr’s circle is zero.

10. What is mean by position of

principal planes?

The planes on which

shear stress is zero are known as principal planes. The position of principal

planes are obtained by equating the tangential stress to zero.

11. What is solid length?

The

length of a spring under the maximum compression is called its solid length. It

is the product of total number of coils and the diameter of wire.

Ls = nt x d

Where, nt = total number of coils.

12.

Define spring rate (stiffness).

The

spring stiffness or spring constant is defined as the load required per unit

deflection of the spring.

K= W/y Where , W - load

y- Deflection

13. Define pitch.

Pitch of

the spring is defined as the axial distance between the adjacent coils in

uncompressed state. Mathematically

Pitch=free length n-1

14. Define helical

springs.

The

helical springs are made up of a wire coiled in the form of a helix and are

primarily intended for compressive or tensile load.

15. What are the

differences between closed coil & open coil helical springs? Closed coil

spring

The

spring wires are coiled very closely, each turn is nearly at right angles to

the axis of helix . Helix angle is less (70 to 10o)

Open coil spring

The wires

are coiled such that there is a gap between the two consecutive turns. Helix

angle is large (>10o)

16.

Write the assumptions in the theory

of pure torsion.

1. The

material is homogenous and isotropic.

2. The

stresses are within elastic limit

3.

C/S which are plane before applying

twisting moment remain plane even after the application of twisting moment.

4. Radial

lines remain radial even after applying torsional moment.

5. The

twist along the shaft is uniform

17.

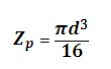

Define : Polar Modulus

Polar modulus is

defined as the ratio of polar moment of inertia to extreme radial distance of

the fibre from the centre.

18. Write the equation for the polar

modulus for solid circular section

Related Topics