Chapter: Mechanical : Maintenance Engineering : Principles and Practices of Maintenance Planning

Importance and benefits of sound Maintenance systems

Objectives and Principles of Planned

Maintenance Activity

Analysis

of repetitive equipment failures.

Estimation

of maintenance costs and evaluation of alternatives.

Assessing

required skills required for maintenance personnel.

Reviewing personnel transfers to and from

maintenance organizations assessing and reporting safety hazards associated

with maintenance of equipment.

Assessing

required maintenance tools

and skills required

for efficient maintenance

of equipment.

Assessing

required skills required for maintenance personnel.

Reviewing personnel transfers to and from

maintenance organizations assessing and reporting safety hazards associated

with maintenance of equipment.

Importance and benefits of sound

Maintenance systems

Minimization of down time

Life of equipment

Safety and smooth operation

Backup Supply

Reliability

Working environment

profit

1. Maintenance organization

·

Organizing is the process of arranging resources

(people, materials, technologyetc.) together to achieve the organization’s

strategies and goals.

·

The way in which the various parts of an

organization are formally arranged is referred to as the organization structure.

·

It is a system involving the interaction of inputs

and outputs.

·

However, there is no universally accepted

methodology for designingmaintenance systems, i.e., no fully structured

approach leading to an optimalmaintenance system (i.e., organizational

structure with a defined hierarchy ofauthority and span of control; defined

maintenance procedures and policies, etc.).Identical product

organizations, but different in technology advancement andproduction size, may

apply different maintenance systems and the differentsystems may run

successfully.

·

So, maintenance systems are designed

usingexperience and judgment supported by a number of formal decision tools

andtechniques.

·

Maintenance managers must have the capabilities to

create a division of laborfor maintenance tasks to be performed and then

coordinate results to achieve acommon purpose.

·

Solving performance problems and capitalizing on

opportunitiescould be attained through selection of the right persons, with the

appropriatecapabilities, supported by continuous training and good incentive

schemes, in orderto achieve organization success in terms of performance

effectiveness andefficiency..

2.Maintenance

Organization Objectives and Responsibility

A maintenance organization and its position in the

plant/whole organization is heavily impacted by the following elements or

factors:

•

Type of business, e.g., whether it is high

tech, labor intensive, production or service;

•

Objectives: may include profit maximization,

increasing market share and other social objectives;

•

Size and structure of the organization;

•

Culture of the organization; and

•

Range of responsibility assigned to maintenance.

Organizations

seek one or several of the following objectives: profit maximization, specific

quality level of service or products, minimizing costs, safe and clean

environment, or human resource development. It is clear that all of these

objectives are heavily impacted by maintenance and therefore the objectives of

maintenance must be aligned with the objectives of the organization.

The principal responsibility of

maintenance is to provide a service to enable an organization to achieve its

objectives. The specific responsibilities vary from one organization to

another; however they generally include the following according to Duffuaa et

al. (1998):

1.

Keeping assets and equipment in good condition,

well configured and safe to perform their intended functions;

2.

Perform

all maintenance activities

including preventive, predictive;

corrective, overhauls, design modification and

emergency maintenance in an efficient and effective manner;

3.

Conserve and control the use of spare parts and

material;

4.

Commission new plants and plant expansions; and

5.

Operate utilities and conserve energy.

The above responsibilities and

objectives impact the organization structure for maintenance as will be shown

in the coming sections.

3.Determinants

of a Maintenance Organization

The maintenance organization’s structure

is determined after planning the maintenance capacity. The maintenance capacity

is heavily influenced by the level of centralization or decentralization

adopted. In this section the main issues that must be addressed when forming

the maintenance organization’s structure are presented.

The issues are: capacity planning, centralization vs decentralization

and in-house vs outsourcing.

4.Maintenance

Capacity Planning

Maintenance capacity planning determines the

required resources for maintenance including the required crafts,

administration, equipment, tools and space to execute the maintenance load

efficiently and meet the objectives of the maintenance department. Critical

aspects of maintenance capacity are the numbers and skills of craftsmen

required to execute the maintenance load. It is difficult to determine the

exact number of various types of craftsmen, since the maintenance load is

uncertain. Therefore accurate forecasts for the future maintenance work demand

are essential for determining the maintenance capacity. In order to have better

utilization of manpower, organizations tend to reduce the number of available

craftsmen below their expected need. This is likely to result in a backlog of

uncompleted maintenance work. Maintenance Organization 7

5.

Centralization vs Decentralization

The decision to organize maintenance in a centralized,

decentralized or a hybrid form depends to a greater extent on the organization

is philosophy, maintenance load, size of the plant and skills of craftsmen. The

advantages of centralization are:

1. Provides more

flexibility and improves

utilization of resources such highly skilled crafts and special

equipment and therefore results in more efficiency;

2. Allows more

efficient line supervision;

3. Allows more

effective on the job training; and

4. Permits the

purchasing of modern equipment.

disadvantages:

1. Less utilization

of crafts since more time is required for getting to and from jobs;

2. Supervision of

crafts becomes more difficult and as such less maintenance control is achieved;

3. Less specialization on

complex hardware is

achieved since different persons work on the same hardware;

and

4. More costs of

transportation are incurred due to remoteness of some of the maintenance work.

In a decentralized maintenance

organization, departments are assigned to specific areas or units. This tends

to reduce the flexibility of the maintenance system as a whole. The range of

skills available becomes reduced and manpower utilization is usually less

efficient than in a centralized maintenance. In some cases a compromise

solution that combines centralization and decentralization is better. This type

of hybrid is called a cascade system. The cascade system organizes maintenance

in areas and whatever exceeds the capacity of each area is challenged to a

centralized unit. In this fashion the advantages of both systems may be reaped.

For more on the advantages and disadvantages of centralization and de-

centralization see Duffuaa et al. (1998) and Niebel (1994).

6

In-house vs Outsourcing

At this level management considers the sources for

building the maintenance capacity. The main sources or options available are

in-house by direct hiring, outsourcing, or a combination of in-house and

outsourcing. The criteria for selecting sources for building and maintaining

maintenance capacity include strategic considerations, technological and

economic factors. The following are criteria that can be employed to select

among sources for maintenance capacity:

1.

Availability and dependability of the source on a

long term basis;

2.

Capability of the source to achieve the objectives

set for maintenance by the organization and its ability to carry out the

maintenance tasks;

3.

Short term and long term costs;

4.

Organizational secrecy in some cases may be

subjected to leakage;

5.

Long term impact on maintenance personnel

expertise; and

6.

Special agreement by manufacturer or regulatory

bodies that set certain specifications for maintenance and environmental

emissions.

Examples

of maintenance tasks which could be outsourced are:

1.

Work for which the skill of specialists is

required on a routine basis and which is readily available in the market on a

competitive basis, e.g.,:

• Installation and

periodic inspection and

repair of automatic

fire sprinkler systems;

•

Inspection and repair of air conditioning systems;

•

Inspection and repair of heating systems; and

•

Inspection and repair of main frame computers etc.

2.

When it is cheaper than recruiting your own staff

and accessible at a short notice of time.

The issues and criteria presented

in the above section may help organizations in designing or re-designing their

maintenance organization.

7.Design

of the Maintenance Organization

A maintenance organization is subjected to

frequent changes due to uncertainty and desire for excellence in maintenance.

Maintenance and plant managers are always swinging from supporters of

centralized maintenance to decentralized ones, and back again. The result of

this frequent change is the creation of responsibility channels and direction

of the new organization’s accomplishments vs the

accomplishments of the former structure. So, the craftsmen have to adjust to

the new roles. To establish a maintenance organization an objective method that

caters for factors that influence the effectiveness of the organization is

needed. Competencies and continuous improvement should be the driving

considerations behind an organization’s design

and re-design.

8

Current Criteria for Organizational Change

Many organizations were re-designed to fix a perceived

problem. This approach in many cases may raise more issues than solve the

specific problem (Bradley, 2002). Among the reasons to change a specific

maintenance organization’s design are:

1. Dissatisfaction with

maintenance performance by

the organization or plant management;

2. A desire for

increased accountability;

4 . A desire to minimize manufacturing costs, so

maintenance resources are moved to report to a production supervisor, thereby

eliminating the (perceived) need for the maintenance supervisor;

4.

Many plant managers are frustrated that

maintenance seems slow paced, that is, every job requires excessive time to get

done. Maintenance people fail to understand the business of manufacturing, and

don’t seem to

be part of the team. This failure results in decentralization or distribution

of maintenance resources between production units; and

5.

Maintenance costs seem to rise remarkably, so more

and more contractors are brought in for larger jobs that used to get done

in-house.

9 Criteria

to Assess Organizational Effectiveness

Rather than designing the organization to solve a

specific problem, it is more important to establish a set of criteria to

identify an effective organization. The following could be considered as the

most important criteria:

1.

Roles and responsibilities are clearly defined and

assigned;

2.

The organization puts maintenance in the right

place in the organization;

3.

Flow of information is both from top-down and

bottom-up;

4.

Span of control is effective and supported with

well trained personal;

5.

Maintenance work is effectively controlled;

6.

Continuous improvement is built in the structure;

7.

Maintenance costs are minimized; and

8.

Motivation and organization culture.

10.

Basic Types of Organizational Models

To provide consistently the capabilities listed

above we have to consider three types of organizational designs.

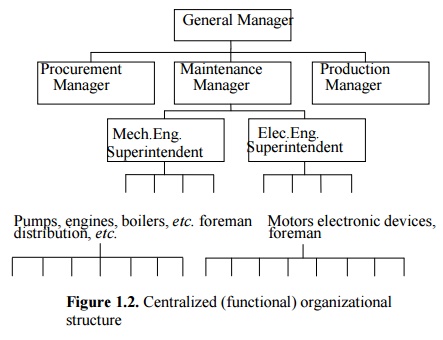

•

Entralized maintenance. All crafts and related

maintenance functions report to a central maintenance manager as depicted in

Figure 1.2. The strengths of this structure are: allows economies of scale;

enables in-depth skill development; and enables departments (i.e., a

maintenance department) to accomplish their functional goals (not the overall

organizational goals). This structure is best suited for small to medium- size

organizations. The weaknesses of this structure are: it has slow response time

to environmental changes; may cause delays in decision making and hence longer

response time; leads to poor horizontal coordination among departments and

involves a restricted view of organizational goals.

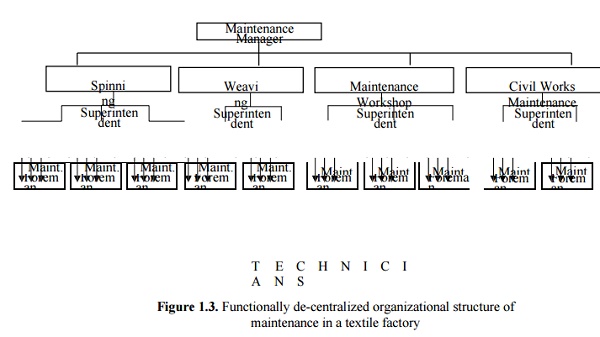

•

Decentralized maintenance. All crafts and

maintenance craft support staff report to operations or area maintenance as

described in Figure 1.3. The strengths of this structure are that it allows the organization to achieve adaptability and

coordination in production units and efficiency in a centralized overhaul group and it facilitates

effective coordination both within and between

maintenance and other departments. The weaknesses of this structure are

that it has potential

•

• for excessive administrative overheads and may

lead to conflict between departments.

•

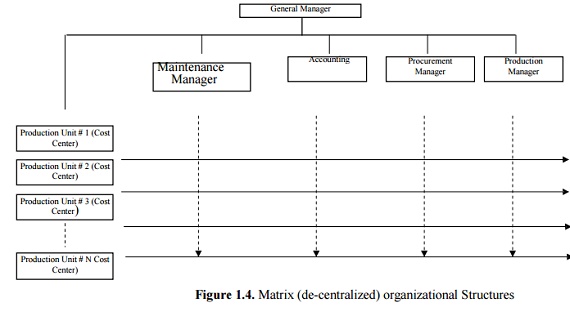

Matrix

structure, a form of a hybrid

structure. Crafts are allocated in some proportion to production units or area

maintenance and to a central maintenance function that supports the whole plant

or organization. The strengths of this matrix structure are: it allows the

organization to achieve coordination necessary to meet dual demands from the

environment and flexible sharing of human resources. The weaknesses of this

structure are: it causes maintenance employees to experience dual authority

which can be frustrating and confusing; it is time consuming and requires

frequent meetings and conflict resolution sessions. To remedy the weaknesses of

this structure a management with good interpersonal skills and extensive

training is required.

11.Material and Spare Parts Management

The

responsibility of this unit is to ensure the availability of material and spare

parts in the right quality and quantity at the right time at the minimum cost.

In large or medium size organizations this unit may be independent of the

maintenance organization; however in many circumstances it is part of

maintenance. It is a service that supports the maintenance programs. Its

effectiveness depends to a large extent on the standards maintained within the

stores system. The duties of a material and spare parts unit include:

1.

Develop in coordination with maintenance effective

stocking polices to minimize ordering, holding and shortages costs;

3.

Keep good inward, receiving, and safe keeping of

all supplies;

4.

Issue materials and supplies;

5.

Maintain and update records; and

6.

Keep the stores orderly and clean.

12.

Establishment of Authority and Reporting

Overall administrative control usually rests with

the maintenance department, with its head reporting to top management. This

responsibility may be delegated within the maintenance establishment. The

relationships and responsibility of each maintenance division/section must be

clearly specified together with the reporting channels. Each job title must

have a job description prescribing the qualifications and the experience needed

for the job, in addition to the reporting channels for the job.

13.

Quality of Leadership and Supervision

The organization, procedures, and practices

instituted to regulate the maintenance activities and demands in an industrial

undertaking are not in themselves a guarantee of satisfactory results. The

senior executive and his staff must influence the whole functional activity.

Maintenance performance can never rise above the quality of its leadership and

supervision. From good leadership stems the team- work which is the essence of

success in any enterprise. Talent and ability must be recognized and fostered;

good work must be noticed and commended; and carelessness must be exposed and

addressed.

14.

Incentives

The varied nature of the maintenance tasks, and

differing needs and conditions arising, together with the influence of

production activity, are not attuned to the adoption of incentive systems of

payment. There are, however, some directions in which incentives applications

can be usefully considered. One obvious case is that of repetitive work. The forward

planning of maintenance work can sometimes lead to an incentive payment

arrangement, based on the completion of known tasks in a given period, but care

must be taken to ensure that the required standards of work are not

compromised. In some case, maintenance incentives can be included in output

bonus schemes, by arranging that continuity of production, and attainment of

targets, provides rewards to both production and maintenance personnel.

15.

Education and Training

Nowadays it is also recognized that the employers

should not only select and place personnel, but should promote schemes and

provide facilities for their further education and training, so as to increase

individual proficiency, and provide recruits for the supervisory and senior

grades. For senior staff, refresher courses comprise lectures on specific

aspects of their work; they also encourage the interchange of ideas and

discussion.

The further education of technical grades, craft

workers, and apprentices is usually achieved through joint schemes, sponsored

by employers in conjunction with the local education authority. Employees

should be encouraged to take advantage of these schemes, to improve proficiency

and promotion prospects.

A normal trade background is

often inadequate to cope with the continuing developments in technology. The

increasing complexity and importance of maintenance engineering warrants a

marked increase in training of machine

operators and maintenance craftsmen through formal

school courses, reinforced by informed instruction by experienced supervisors.

The organization must have a well

defined training program for each employee. The following provides guidelines

for developing and assessing the effectiveness of the training program:

•

Evaluate current personnel performance;

•

Assess training need analysis;

•

Design the training program;

•

Implement the program; and

•

Evaluate the program effectiveness.

The evaluation is done either

through a certification program or by assessing the ability to achieve desired

performance by persons who have taken a particular training program.

The implementation of the above

five steps provides the organization with a framework to motivate personnel and

improve performance.

16.

Management and Labor Relations

The success of an undertaking depends

significantly on the care taken to form a community of well-informed, keen, and

lively people working harmoniously together. Participation creates satisfaction

and the necessary team spirit. In modern industry, quality of work life (QWL)

programs have been applied with considerable success, in the form of management

conferences, work councils, quality circles, and joint conferences identified

with the activities. The joint activities help the organization more fully

achieve its purposes.

17.

Summary

This chapter considered organizing

as one of the four functions of management. It is

the process of arranging resources (people, materials, technology, etc.)

together to achieve the organization’s

strategies and goals. Maintenance organization structure is the way various

part of the maintenance organization is formed including defining

responsibilities and roles of units and individuals. A set of criteria are

provided to assess and design organization structures and the main issues to be

addressed are outlined. The issues include centralization, decentralization and

outsourcing. The chapter describes three types of organization structures. In

addition, several functions that could support maintenance organization such as

material and spare management, training and the management of labor relations are

presented.

Related Topics