Chapter: Mechanical : Dynamics of Machines : Forced Vibration

Forced Vibration

FORCED VIBRATION

1 INTRODUCTION:

When a system is subjected continuously to time

varying disturbances, the vibrations resulting under the presence of the

external disturbance are referred to as forced vibrations.

Forced

vibration is when an alternating force or motion is applied to a mechanical system. Examples of this

type of vibration include a shaking washing machine due to an imbalance,

transportation vibration (caused by truck engine, springs, road, etc), or the

vibration of a building during an earthquake. In forced vibration the frequency

of the vibration is the frequency of the force or motion applied, with order of

magnitude being dependent on the actual mechanical system.

When a vehicle moves on a rough road, it is

continuously subjected to road undulations causing the system to vibrate

(pitch, bounce, roll etc). Thus the automobile is said to undergo forced

vibrations. Similarly whenever the engine is turned on, there is a resultant

residual unbalance force that is transmitted to the chassis of the vehicle

through the engine mounts, causing again forced vibrations of the vehicle on

its chassis. A building when subjected to time varying ground motion

(earthquake) or wind loads, undergoes forced vibrations. Thus most of the

practical examples of vibrations are indeed forced vibrations.

2 CAUSES RESONANCE:

Resonance

is simple to understand

if you view the spring and mass

as energy storage

elements – with the

mass storing kinetic energy and the spring storing potential energy. As

discussed earlier, when the mass and spring have no force acting on them they

transfer energy back and forth at a rate equal to the natural frequency. In

other words, if energy is to be efficiently pumped into both the mass and

spring the energy source needs to feed the energy in at a rate equal to the

natural frequency. Applying a force to the mass and spring is similar to

pushing a child on swing, you need to push at the correct moment if you want

the swing to get higher and higher. As in the case of the swing, the force

applied does not necessarily have to be high to get large motions; the pushes

just need to keep adding energy into the system.

The

damper, instead of storing energy, dissipates energy. Since the damping force

is proportional to the velocity, the more the motion, the more the damper

dissipates the energy. Therefore a point will come when the energy dissipated

by the damper will equal the energy being fed in by the force. At this point,

the system has reached its maximum amplitude and will continue to vibrate at

this level as long as the force applied stays the same. If no damping exists,

there is nothing to dissipate the energy and therefore theoretically the motion

will continue to grow on into infinity.

3 FORCED VIBRATION OF A SINGLE

DEGREE-OF-FREEDOM SYSTEM:

We saw that when a system is given an initial input

of energy, either in the form of an initial displacement or an initial

velocity, and then released it will, under the right conditions, vibrate

freely. If there is damping in the system, then the oscillations die away. If a

system is given a continuous input of energy in the form of a continuously

applied force or a continuously applied displacement, then the consequent

vibration is called forced vibration. The energy input can overcome that

dissipated by damping mechanisms and the oscillations are sustained.

We will consider two types of forced vibration. The

first is where the ground to which the system is attached is itself undergoing

a periodic displacement, such as the vibration of a building in an earthquake.

The second is where a periodic force is applied to the mass, or object

performing the motion; an example might be the forces exerted on the body of a

car by the forces produced in the engine. The simplest form of periodic force

or displacement is sinusoidal, so we will begin by considering forced vibration

due to sinusoidal motion of the ground. In all real systems, energy will be

dissipated, i.e. the system will be damped, but often the damping is very

small. So let us first analyze systems in which there is no damping.

4 STEADY STATE RESPONSE DUE TO

HARMONIC OSCILLATION:

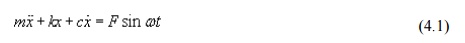

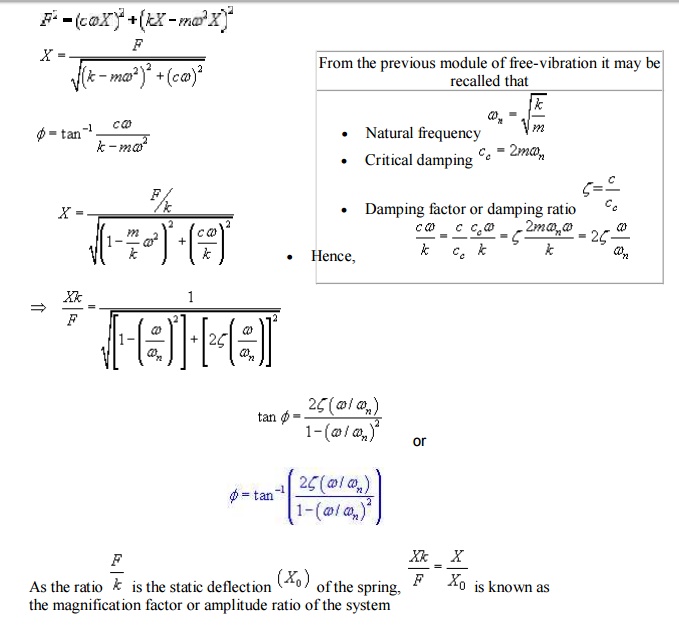

Consider

a spring-mass-damper system as shown in figure 4.1. The equation of motion of

this system subjected to a harmonic force Fsin(wt) can be given by

where, m , k

and c are the mass, spring stiffness

and damping coefficient of the system, F

is the amplitude of the force, w is

the excitation frequency or driving frequency.

Figure

4.1 Harmonically excited system

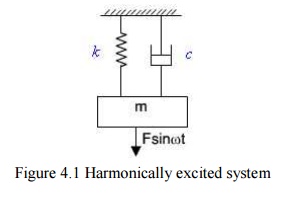

Figure

4.2: Force polygon

The

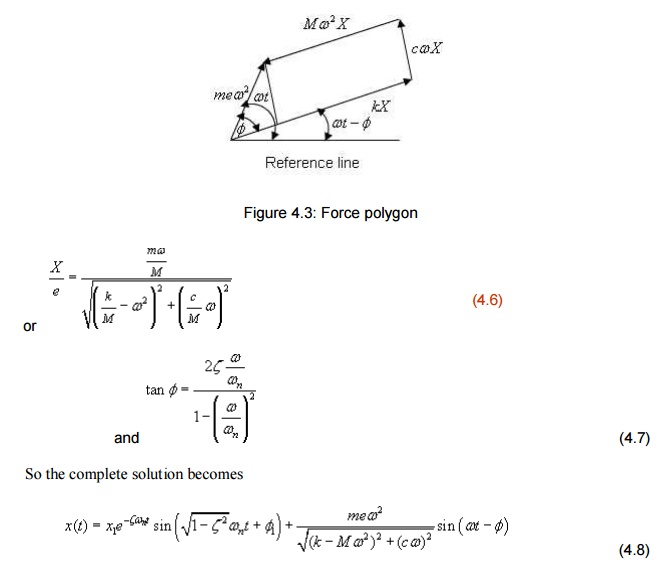

steady state response of the system can be determined by solving equation(4.1)

in many different ways. Here a simpler graphical method is used which will give

physical understanding to this dynamic problem. From solution of differential

equations it is known that the steady state solution (particular integral) will

be of the form

As each

term of equation (4.1) represents a forcing term viz., first, second and third

terms, represent the inertia force, spring force, and the damping forces. The

term in the right hand side of equation (4.1) is the applied force. One may

draw a close polygon as shown in figure 4.2 considering the equilibrium of the

system under the action of these forces. Considering a reference line these

forces can be presented as follows.

From

equation (1), the resultant of the spring force, damping force and the inertia

force will be the applied force, which is clearly shown in figure 4.2.

It may be

noted that till now, we don't know about the magnitude of X and $ which can be easily computed from Figure 2.

Drawing a line CD parallel to AB, from the triangle OCD of Figure 2,

5 FORCED VIBRATION WITH DAMPING:

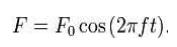

In this

section we will see the behaviour of the spring mass damper model when we add a

harmonic force in the form below. A force of this type could, for example, be

generated by a rotating imbalance.

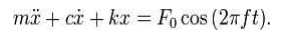

If we

again sum the forces on the mass we get the following ordinary differential

equation:

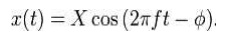

The

steady state solution of this problem can be written as:

The

result states that the mass will oscillate at the same frequency, f, of the

applied force, but with a phase shift φ.

The

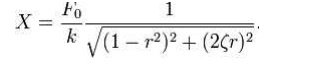

amplitude of the vibration ―X‖ is defined by the following formula.

Where

―r‖ is defined as the ratio of the harmonic force frequency over the undamped natural

frequency of the mass–spring–damper

model.

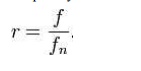

The phase

shift , φ, is

defined by the following formula.

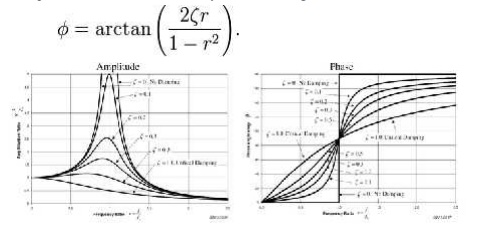

The plot

of these functions, called "the frequency response of the system",

presents one of the most important features in forced vibration. In a lightly

damped system when the forcing frequency nears the natural frequency ( r ~= 1)

the amplitude of the vibration can get extremely high. This phenomenon is

called resonance (subsequently the natural frequency of a system is often

referred to as the resonant frequency). In rotor bearing systems any rotational

speed that excites a resonant frequency is referred to as a critical speed.

If resonance

occurs in a

mechanical system it

can be very

harmful – leading to eventual failure of the system.

Consequently, one of the major reasons for vibration analysis is to predict

when this type of resonance may occur and then to determine what steps to take

to prevent it from occurring. As the amplitude plot shows, adding damping can

significantly reduce the magnitude of the vibration. Also, the magnitude can be

reduced if the natural frequency can be shifted away from the forcing frequency

by changing the stiffness or mass of the system. If the system cannot

be changed, perhaps

the forcing frequency can

be shifted (for

example, changing the speed of the machine generating the force).

The

following are some other points in regards to the forced vibration shown in the

frequency response plots.

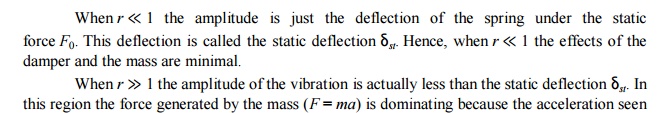

At a

given frequency ratio, the amplitude of the vibration, X, is directly

proportional to the amplitude of the force F0 (e.g. if you double

the force, the vibration doubles)

With

little or no damping, the vibration is in phase with the forcing frequency when

the frequency ratio r < 1 and 180 degrees out of phase when the frequency

ratio r > 1

by the

mass increases with the frequency. Since the deflection seen in the spring, X,

is reduced in this region, the force transmitted by the spring (F = kx) to the

base is reduced. Therefore the mass–spring–damper≫ system is isolating the harmonic

force from the mounting base – referred to as vibration isolation. Interestingly,

more damping actually reduces the effects of vibration isolation when r 1

because the damping force (F = cv) is also transmitted to the base.

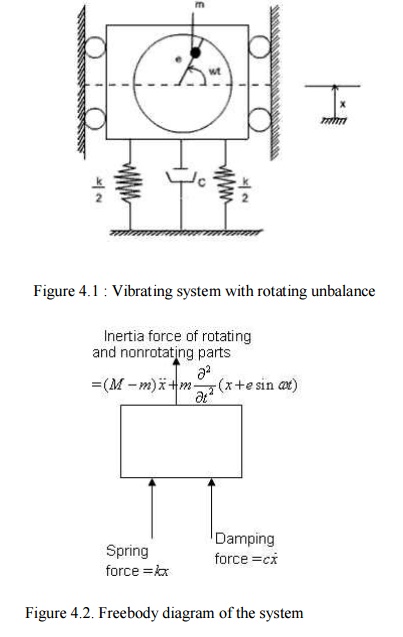

6 ROTATING UNBALANCE FORCED VIBRATION:

One may

find many rotating systems in industrial applications. The unbalanced force in

such a system can be represented by a mass m

with eccentricity e , which is

rotating with angular velocity as shown in Figure 4.1.

Figure

4.1 : Vibrating system with rotating unbalance

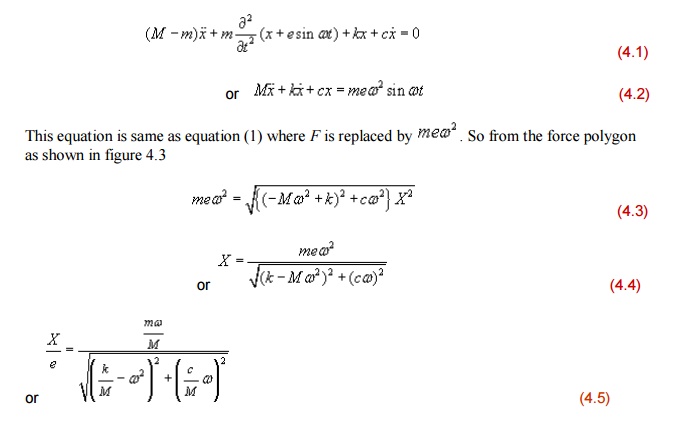

Figure

4.2. Freebody diagram of the system

Let x be

the displacement of the nonrotating mass (M-m) from the static equilibrium

position, then the displacement of the rotating mass m is x+esinwt

From the

freebody diagram of the system shown in figure 4.2, the equation of motion is

7 VIBRATION ISOLATION AND

TRANSMISSIBILITY:

When a

machine is operating, it is subjected to several time varying forces because of

which it tends to exhibit vibrations. In the process, some of these forces are

transmitted to the foundation – which

could undermine the life of the foundation and also affect the operation of any

other machine on the same foundation. Hence it is of interest to minimize this

force transmission. Similarly when a system is subjected to ground motion, part

of the ground motion is transmitted to the system as we just discussed e.g., an

automobile going on an uneven road; an instrument mounted on the vibrating

surface of an aircraft etc. In these cases, we wish to minimize the motion

transmitted from the ground to the system. Such considerations are used in the

design of machine foundations and in order to understand some of the basic

issues involved, we will study this problem based on the single d.o.f model

discussed so far.

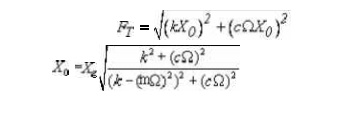

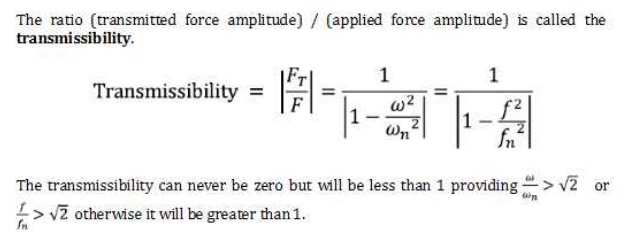

we get the expression for force transmitted to the base as follows:

Vibration Isolators:

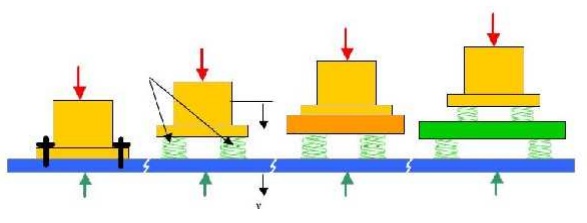

Consider

a vibrating machine; bolted to a rigid floor (Figure 2a).The force transmitted

to the floor is equal to the force generated in the machine. The transmitted

force can be decreased by adding a suspension and damping elements (often

called vibration isolators) Figure 2b , or by adding what is called an inertia

block, a large mass (usually a block of cast concrete), directly attached to

the machine (Figure 2c).Another option is to add an additional level of mass

(sometimes called a seismic mass, again a block of cast concrete) and

suspension (Figure 2d).

Figure

2.Vibrat ion iso lat ion systems: a) Machine bo lted to a rigid foundation

b)

Supported o n iso lat io n springs, rigid fo u ndat io n c) machine attached to

an inertial block. d) Supported on isolation springs, non -rigid foundation

(such as a floor); or machine on isolation springs, seismic mass and seco nd

level of isolator springs

When oscillatory forces arise unavoidably in

machines it is usually desired to prevent these forces from being transmitted

to the surroundings. For example, some unbalanced forces are inevitable in a

car engine, and it is uncomfortable if these are wholly transmitted to the car

body. The usual solution is to mount the source of vibration on sprung

supports. Vibration isolation is measured in terms of the motion or force

transmitted to the foundation. The lesser the force or motion transmitted the

greater the vibration isolation

Suppose that the foundation is effectively rigid

and that only one direction of movement is effectively excited so that the

system can be treated as having only one degree of freedom.

8 RESPONSE WITHOUT DAMPING:

The amplitude of the force transmitted to the

foundations is Where k is the Stiffness of the support

and x(t)

is the displacement of the mass m.

The

governing equation can be determined by considering that the total forcing on

the machine is equal to its mass multiplied by its acceleration (Newton’s

second law)

Related Topics