Chapter: Mechanical : Maintenance Engineering : Repair Methods For Basic Machine Elements

FMEA - Failure Modes and Effects Analysis

FMEA

- Failure Modes and Effects Analysis

The main goal of the FMEA (Failure Mode and

Effect Analysis) is to prevent failures. Therefor it belongs to the important

tools of the quality planning. It is assumed that the general meaning is known.

iQ-FMEA

has been developed under various aspects:

the system has to meet the practical

requirements according to the VDA series of publications

it has to support

the structured process of FMEA sessions through algorithms, tables and methods

the history of a FMEA is to be shown for every step of improvement

experiences (knowledge base) of

previous FMEAs have to be able to enter in current FMEAs. Therefor certain parts

of a FMEA are emphasized as standard. They are independent of the current

product or process.

employees without a lot of

knowledge about information processing have also be able to use the FMEA

FMEA header, that contains

general information for the most common standard forms FMEA versions; each

version describes a segment of the FMEA-development

system elements as units for

analysis functions of a system element possible malfunctions of a function

integrated knowledge base

extensive provisions for

action management

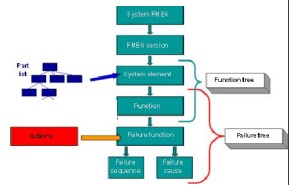

The structure elements in

detail

FMEA header

FMEA id and short description

FMEA type

method of evaluation material

drawings

initial part/process or

optimization analysis extensive text description

entire status of the FMEA

Version

FMEA can have several

versions.

One version describes the

FMEA progress from the realisation of corrective actions to the recommendation

of further actions. A new version closes the predecessor.

cost input after each

session; time and money investments in persons; direct costs cost cumulation

over all sessions of a version and over the whole period of a FMEA divers

further management data on version level

System elements (SE)

any number of system elements

in a version

assignment of a system

element to a SE class. This makes it possible to define arbitrarily structured

search criteria (knowledge base).

SEs can be ordered

hierarchically in a parts list structure

Function and error tree

SEs within the SE hierarchy

are in following relationship with each other: the function of the inferior SEs

(rubberlip) builds a chain to the superior (sealing ring), the function tree

one FMEA may contain several

function trees

the function tree can be set

up top down or bottom up

errors on a lower level can

automatically be taken as a failure cause on a higher level complete support of

system FMEA (see form)

Failure analysis

failure analysis

can be considered in isolation for each malfunction failure analysis can be

made within the function tree

a failure can cause several consecutive

failures

a failure can result from several reasons

you can assign the RPZ factor meaning to a failure sequence

you can assign the RPZ factor occurrence probability and detectability to a failure cause B, E and A from a catalogue, which can be created by the user (VDA, DGQ etc.)

Adjustment actions

The complete feature set of iQ-Projekte is used differentiation in preventive actions (design engineer) and detecting actions (later quality assurance) information about responsible person, appointments, performance, estimation of planned improvements etc. appointment traceability, follow-up actions in case of missed deadlines etc.

FMEA form

form for complete FMEA

form for certain system elements

Knowledgebase

structure

and identification of FMEAs and SEs, which appear similar in other

constructions or processes (for example bore for fit, rotation and parallel

translation)

search algorithms based on class systems

adoption of already described SEs, depending

on RPZ-experiences

Analysis

history of a FMEA

about the version Pareto-diagram to

a version over RPZ

graphic

comparison of the RPZs over SEs and

functions between two versions standard forms

Related Topics