Chapter: Design of Electrical Machines : Synchronous Machines

Design of the field System: Non Salient pole Alternator

Design of

the field System: NonSalient pole Alternator:

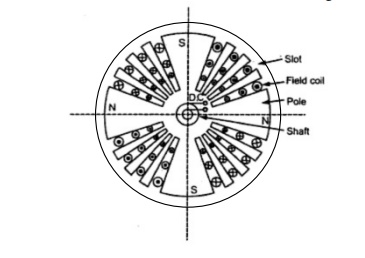

In case

of turbo alternators, the rotor windings or the field windings are distributed

in the rotor slots. The rotor construction of the turbo alternator is as shown

in fig. below.

Normally

70% of the rotor is slotted and remaining portion is unslotted in order to form

the pole. The design of the field can be explained as follows.

(i)

Selection of rotor slots: Total number of rotor

slots may be assumed as 50 – 70 % of stator slots pitches. However the so found

rotor slots must satisfy the following conditions in

order to

avoid the undesirable effects of harmonics in the flux density wave forms.

(a) There

should be no common factor between the number of rotor slot pitches and number

of stator slot pitches.

(b) Number of

wound rotor slots should be divisible by 4 for a 2 pole synchronous machine.

That means the number of rotor slots must be multiple of 4.

(c) Width of

the rotor slot is limited by the stresses developed at the rotor teeth and end

rings.

(ii)

Design of rotor winding

(a) Full load field mmf can be taken as twice the

armature mmf. ATfl = 2 x ATa = 2 x 1.35 x Iph

x Tph x kw /p

(b) Standard

exciter voltage of 110 - 220 volts may be taken. With 15-20 % of this may be

reserved for field control. Hence voltage across each field coil Vf

= (0.8 to 0.85) V/p

(c) Length of

the mean turn lmt = 2L +

1.8 τp + 0.25 m

(d) Sectional

area of each conductor af = ζ x lmt x (If

x Tf) / vf

(e) Assume

suitable value of current density in the rotor winding. 2.5 – 3.0 amp/mm2

for conventionally cooled machines and 8 – 12 amp/mm2 for large and

special cooled machines.

(f)

Find area of all the rotor conductors per pole = 2

x (If x Tf) /δf

(g) Find the

number of rotor conductors per pole = 2 x (If x Tf) / (δf x af)

(h) Number of

field conductors per slot = 2 x (If x Tf) / (δf x af x sr),

where sr is the number of rotor slots.

(i) Resistance

of each field coil Rf = ζ x lmt x Tf

/ af

(j) Calculate

the current in the field coil If = vf/ Rf

Based on

the above data dimensions may be fixed. The ratio of slot depth to slot width

may be taken between 4 and 5. Enough insulation has to be provided such that it

with stands large amount of mechanical stress and the forces coming on the

rotor.

The

following insulation may be provided for the field coil.

(i)

All field conductors are provided with mica tape

insulation.

(ii)

Various turns in the slots are separated from each

other by 0.3 mm mica separators.

(iii)

0.5 mm hard mica cell is provided on all the field

coil.

(iv)

Over the above insulation, 1.5 mm flexible mica

insulation is provided.

(v)

Lastly a steel cell of o.6 mm is provided on the

whole field coil.

Ex. 1.

Design the rotor of a 3 phase 20 MVA, 11 kV, 3000 rpm, 50 Hz, turbo alternator

with the following design data. Diameter at the air gap = 0.8 m, Gross length =

2.4 m, stator turns per phase = 18, Number of stator slots = 36, Exciter

voltage = 220 volts, Estimate (i) Number of rotor slots, (ii) area of the field

conductor (iii) Turns in the filed coil and (iv) Field current

Soln: (i)

Number of rotor slots : Selection of rotor slots: Total number of rotor slots

may be assumed as 50 – 70 % of stator slots. Normally 70% of the rotor is

slotted and remaining portion is unslotted.

Number of

stator slots = 36

Hence

number of slots pitches must be between 18 to 26 Satisfying the conditions number

of rotor slot pitches = 23 Number of wound slots = 16

(ii)Area

of the field conductor

Assuming

40 volts in the field regulator voltage across filed coil = 220 – 40 /2 = 90

volts Armature ampere turns /pole ATa=1. 35 Iph Tph

Kw /p

= 1.35 x

1050 x 18 x 0.955/ 1 = 24300 AT Assuming full load field ampere turns/pole = 2

x ATa = 2 x 24300 = 48600 AT Mean length of the turn is given by lmt = 2L +

1.8 τp + 0.25 m

= 2 x 2.4 +

1.8 x 1.256 + 0.25

= 7.31 m

Area of

the field conductor af = ζ x lmt x (If

x Tf) / vf

= 0.021 x

7.31 x 48600/90

= 83.22 mm2

(iii)

Number of field turns : Full load field ampere

turns/pole = 48600 AT Full load field ampere conductors/pole = 2 x 48600 AT

Assuming

a current density of 2.6 amp/mm2

Area of

all the rotor conductors = 2 x 48600 / 2.6 = 37400 mm2

Number of

rotor conductors/pole = 37400/84 = 445

Number of

wound slots per pole = 16/2 = 8

Number of

conductors per slot = 445/8 = 56

Modified

value of conductors per pole = 56 x 8 = 448

Number of

field turns per pole Tf = 448/2 = 224

Number of

coils per pole = 8/2 = 4

(iv)

Field current: Resistance of the field coil Rf = ζ x lmt x Tf

/ af

= 0.021 x

7.31 x 224/ 84

= 0.41

Current

in the field winding If = Vc/ Rf

= 90/0.41 = 219 Amps.

Related Topics