Chapter: Aquaculture Engineering : Buildings and Superstructures

Design of major parts - Buildings and Superstructures in Aquaculture Engineering

Design of major parts

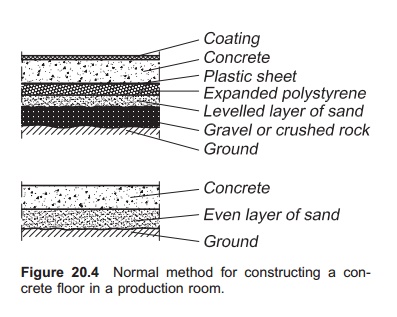

Floors

In aquaculture facilities concrete is normally used for the floor (Fig. 20.4). Iron mats or rods are used to reinforce the concrete. The normal slab thickness is 10–15 cm, but it might be greater under the walls and pillars because the floor needs to withstand the additional weight transferred from the wall or pillars. In cold climates is it necessary to use PS as insulation under the floor. To avoid frost heave either flank insulation or a ring foundation can be used for the building. If using flank insulation, it is laid under the surface, extending 1.5–2 m outside the flanks of the building. In this way frost inhibit from going down in the ground close to the building; it will go some distance out, so does not reach into the building and the problem with frozen ground is eliminated. If using a ring foundation this goes down to below the frozen ground and ensures that the building remains independent of the frozen ground. The thickness of a ring foundation wall is 10–20 cm, and typical depths are 1.5–2 m below ground level.

In the production room, at least, it is necessary to have a smooth surface on the floor that is easy to clean. It is normal to seal the floor with some type of epoxy two component paint, especially suitable for concrete surfaces, to increase the smoothness of the floor so that it is easier to clean. However, it must not be too slippery; in the walkways, sand grains can be included in the epoxy paint.

To keep the floor clean and dry, it is important to have sufficient slope on the floor and enough gullies to collect the water; the recommended slope is from 0.1 to 1%. It is better to have too great a slope than too little. Farms have also used heat cables in the concrete floor to keep the floor dry, but this is very expensive.

Walls

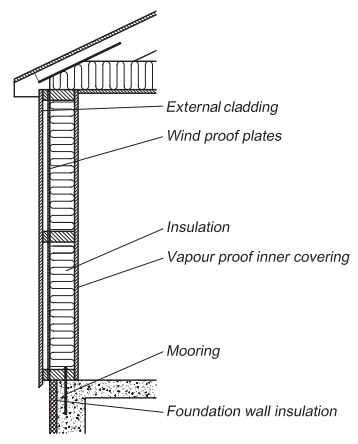

The walls must be constructed to stay upright and keep the roof in position, keep the building stable, and prevent wind damage to or deformation of the building. How the wall is constructed depends whether it is insulated or not, the material used, and the load carrying system employed.

If the wall is not insulated, an open construction is recommended, because then no ventilation system is necessary and the air inside will be the same as the air around the building. It is, however, an advantage to have some walls to shield the inside of the building from the wind.

A closed or insulated wall construction, if this is necessary, consists of the following three major parts:

· Exterior covering to shelter and protect the load-carrying system

· Wall construction including the load-carrying system and insulation layer

· Internal covering to screen the inside and protect the load-carrying system.

These parts can be separate, or all the parts can be included in one construction, depending on the material used.

Several materials can be used for construction of the wall (Fig. 20.5). One major material could be used or the wall can be a mix of different materials. The major materials are wood, steel and concrete. A normal weathertight wall (the same principle is also used in the roof) of wood or steel can be constructed as described below.

The exterior covering that protects the wall construction and prevents ingress of rain and wind can be wooden boarding or metal plates (steel or aluminium). Under these boards or plates, sheathing cardboard or plates can be used to stop strong wind and driving rain penetrating into the wall construction.

In the farming room, plastic-covered chipboard sheets or metal plates can be used for the internal wall covering. To avoid humidity from the production room penetrating into the wall, a damp course is used under the plates and on the wall construction. This is a thin clear plastic sheet, and is of greatimportance in protecting the wall against high humidity and possible decay.

Timber framework is widely used; typical plank sizes are 5 cm × 10 cm, or 5 cm × 15 cm, which gives walls of thickness 10 cm or 15 cm, respectively. The planks are joined to form a frame that is torsion stable in every direction. The frame is typically covered on both sides with metal plates or wood panelling.

If using concrete, the thickness of the walls is 10–30 cm, and iron bars are used as reinforcement. If the building is insulated, PS can be an integral part of the wall. Because the PS is enclosed in concrete, problems with toxic gases from the PS in the event of fire are avoided. When building concrete walls, formwork must be used on both sides before the concrete is poured in and the hardening process can take place. Concrete blocks or light concrete blocks may also be used. This is a simple way to build a wall, where no formwork is needed. The blocks are laid with cement mortar. Blocks are also delivered with integral insulation. The concrete or concrete blocks represent the total wall construction, and will keep the roof in position, so they function as the load-carrying system.

The exterior and internal coverings are easy to apply to concrete walls. The concrete can be plastered and painted so a smooth surface that is easy to clean can be established on both sides (Fig. 20.6).When using concrete and light concrete, a weathertight construction is achieved. Some kind of ventilation is therefore necessary, even if the walls are not insulated, to avoid excessive humidity.

Related Topics