Chapter: Civil : Railway Airport Harbour Engineering : Railway Engineering : Railway Accidents and Disaster Management

Derailment and its Causes

Derailment and its Causes

As mentioned earlier, out of all

the various types of railway accidents, derailments are the most common. In the

case of a derailment, an engine or a wagon skids off the railway track due to

one or more relevant factors crossing their safety limits. Derailment may

generally be of two types.

Sudden derailments due to wheel

jumping off the rails This type of derailment is not

characterized by a mounting mark on the rails but by a drop mark on the

sleepers. It occurs when the derailing forces are high enough to force the

wheel to suddenly jump off the rails. The probable causes of this type of

derailment are listed below.

(a) Excessive

speeds, particularly at a curve or turnout

(b) Sudden

shifting of load

(c) Improperly

loaded vehicles

(d) Sudden

variation in drawbar forces caused due to braking or acceleration or improper

train operation

(e) Resonant

rolling, rising, or hunting

(f) Broken

wheels or axles

(g) Failure

of vehicle components

(h) Presence

of some obstruction on the track

(i) Failure

of track components. If both the wheels drop on the inside of the track, it may

be a case of track distortion or gauge expansion.

Gradual derailment due to flange

climbing This type of derailment is caused by the wheel flanges

gradually climbing onto the rails, thus leaving mounting marks on the rail.

Such a derailment occurs when the derailing forces overcome the stabilizing

forces but are not high enough to cause a sudden derailment. In this case, the

unstable condition of the track causes the wheels to climb onto the rail, ride

over it, and finally slip and slide off it. It is difficult to establish the

prima facie cause behind this kind of derailment, and detailed investigations

need to be carried out so as to finally arrive at the exact cause for the same.

The reason for such an accident may be the single or joint effect of the

following factors.

(a) Track

defects

(b) Vehicular

defects

(c) Unfavourable

operating techniques

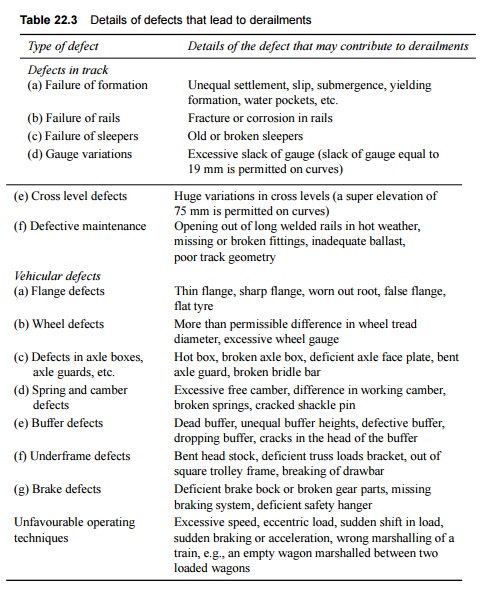

All these

causes are further elaborated upon in Table 22.3.

Table 22.3 Details of defects that

lead to derailments

1 Derailments on Turnouts

A large number of derailments

occur on turnouts because this is where vehicles change the track they are on.

The reasons for these derailments are generally as follows.

(a) Improper

manipulation of points

(b) Gaping

points

(c) Track

defects

(d) Worn out

wheel flanges

(e) High wing

rail and loose crossing bolts

2 Nadal's Formula for Derailment Analysis

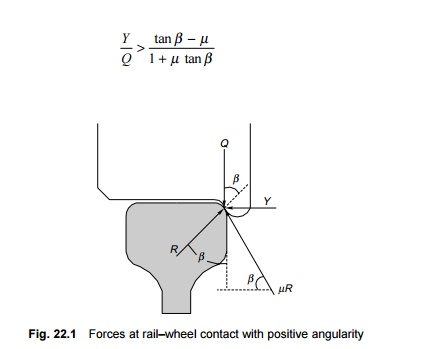

At the time of derailment, when

the wheel flange is in the process of climbing onto the rail, certain forces

act at the part of contact between the rail and the wheel, which lie at

positive angularity to each other as shown in Fig. 22.1.

Nadal's formula for safety against derailment is

where Y is the flange force, Q is the

instantaneous wheel load, R is the normal reaction of the rail, m R is the frictional force acting upwards, m is the coefficient of friction between the wheel flange and

the rail, and b is the

flange angle. Y/Q is known as the derailment coefficient.

Nadal's formula provides an important criterion for the assessment of the

stability of rolling stock. It also has practical use in the investigation of

derailments. Based on Nadal's formula, the factors that contribute to

derailments, whether due to track defects, vehicular defects, or unfavourable

operational techniques, are as follows.

(a) Increase

of flange force Y

(b) Decrease

of instantaneous wheel load Q

(c) Increase

of coefficient of friction between the wheel flange and the rail (m) . This is normally the consequence of a rusted rail, a newly

turned wheel standing on the rail, sharp flanges, etc.

(d) Increase

in positive angle of attack condition ( b )

(e) Increase

in positive eccentricity. This increases primarily due to the slope of the

wheel flange becoming steeper.

(f) Persistent angular running of the axle.

Related Topics