Chapter: Protection and Switchgear : Theory of Circuit Interruption

Current Chopping

current chopping

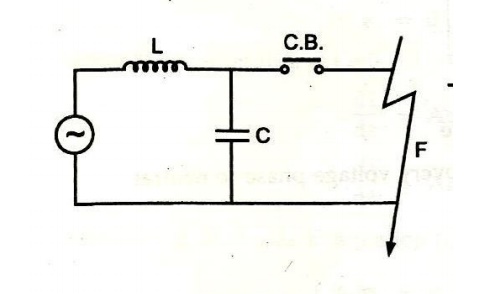

Current chopping is a term that came to our

vocabulary with the advent of vacuum switching which was commercially started

back in the 1950‘s. Earlier switching means in air or oil are in terms of

dielectric recovery rate relatively slow and as the main contacts would part

the arc would go through several zero crossings before it would finally go out

and the dielectric strength across the now open gap be strong to prevent a

restrike, and thus continuation of current for a further half cycle. With the

introduction of vacuum as a dielectric medium that has a completely different

characteristic to that of air or oil dielectrics in so much that it has a very

rapid dielectric recovery rate. Upon opening the main contacts of a vacuum

interrupter whether is be a circuit breaker or a contactor, high velocity

movements are easily obtained because of the low mass and small movements

required to obtain arc isolation up to limited high voltages. As such, the arc

will be extinguished at the first current zero and within half a cycle. Because

of the rapid recovery rate of the dielectric, the arc, in vacuum interrupter

will tend to go out before current zero which will result in an instantaneous current

drop to zero and lead to an induced voltage or voltage transient being

generated to down-stream equipment.

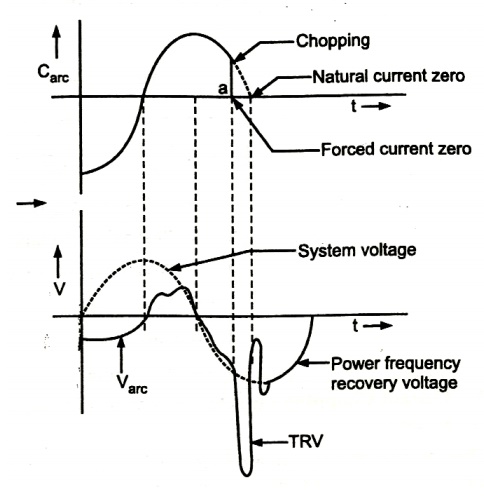

This can be seen by calculating the formula. Vt

= IC xZ0 Vt – Voltage Transient IC – Current Chop Z0 – Surge Impedance Therefore

if the current chop is .9 of an amp and the surge impedance is 3,000 ohm‘s, the

voltage transient will equal 2700 volts on top of the RMS system voltage

whether it be 4160 or 5KV. However if the current chop is 5 amps times surge

impedance of 3,000 ohms, then the voltage transient can equal 15KV on top of

the RMS supply voltage. You will notice from the above that some assumptions

are made with regards to surge impedance values which are difficult to obtain

and vary per circuit. In addition, the voltage transient value that a motor or

dry type transformer will withstand is difficult to obtain from motor and

transformer manufacturers. Therefore Joslyn Clark has taken the approach in

their designs by the contact material mix gives an interrupt characteristic

more than capable of handling the maximum horsepower rating lock rotor currents

in terms of interrupt level and keeping the chopping current to an absolute

minimum.

Over the years this philosophy has proven

itself as unlike other manufacturers we have yet to see motor insulation

problems created by our contactor. The motors manufactured to NEMA design

standards which we consider high class or on motors produced to IEC standards

which we consider to be of a lower class, cheaper version.

Related Topics