Chapter: Mechanical : Automobile Engineering : Vehicle Structure and Engines

Components of an Engine

Components of an Engine;

Even though reciprocating internal combustion engines look

quite simple, they are highly complex machines. There are hundreds of

components that have to perform their functions satisfactorily to produce

output power. There are two types of engines, viz., spark ignition (S1) and

compression-ignition (CI) engine. Let us now go through the important engine

components and the nomenclature associated with an engine.

Terms connected with i.c.

engines;

·

Bore: The inside diameter of the

cylinder is called bore

·

Stroke: The linear distance along

the cylinder axis between two limiting position s is called stroke.

·

Top Dead Center ( T.D.C.) : the top

most position of the piston towards cover end side of the cylinder is

called T.D.C.

·

Bottom dead Center ( B.D.C.) : The

lowest position of the piston towards the crank end side of the cylinder

is called B.D.C.

·

Clearance Volume : The

volume contained in the cylinder above the top of the piston , when the

piston is at top dead center , is called the clearance volume.

·

Swept Volume: The

volume swept through by the piston in moving between T.D.C. and B.D.C,

is called swept volume or piston displacement.

·

Compression Ratio: It is the

ratio of Total cylinder volume to clearance volume

Definition of

‘Engine’

An

engine is a device, which transforms one form of energy into another form.

Normally, most of the engines convert thermal energy into

mechanical work and therefore they are called ‘heat

engines’.

Engine

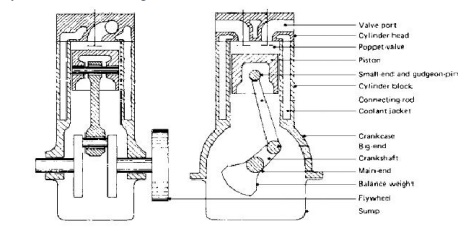

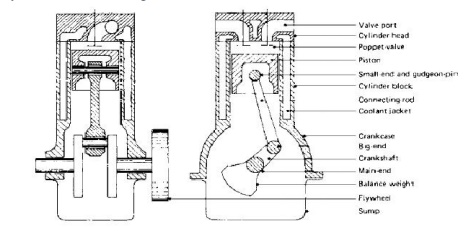

Components

The

major components of the engine and their functions are briefly described below.

Cylinder Block:

The cylinder block is the main supporting structure for the

various components. The cylinder of a multicylinder engine is cast as a single

unit, called cylinder block. The cylinder head is mounted on the cylinder

block.

The cylinder head and cylinder block are provided with water

jackets in the case of water-cooling with cooling fins in the case of

air-cooling. Cylinder head gasket is incorporated between the cylinder block

and cylinder head. The cylinder head is held tight to the cylinder block by

number of bolts or studs. The bottom portion of the cylinder block is called

crankcase. A cover called crankcase, which becomes a sump for lubricating oil

is fastened to the bottom of the crankcase. The inner surface of the cylinder

block, which is machined and finished accurately to cylindrical shape, is

called bore or face.

Cylinder

As the name implies it is a cylindrical vessel or space in

which the piston makes a reciprocating motion. The varying volume created in

the cylinder during the operation of the engine is filled with the working

fluid and subjected to different thermodynamic processes. The cylinder is

supported in the cylinder block.

Piston

It is a cylindrical component fitted into the cylinder forming

the moving boundary of the combustion system. It fits perfectly (snugly) into

the cylinder providing a gas-tight space with the piston rings and the

lubricant. It forms the first link in transmitting the gas forces to the output

shaft.

Combustion Chamber

The space enclosed in the upper part of the cylinder, by the

cylinder head and the piston top during the combustion process, is called the

combustion chamber. The combustion of fuel and the consequent release of

thermal energy results in the building up of pressure in this part of the

cylinder.

Inlet Manifold

The pipe which connects the intake system to the inlet valve

of the engine and through which air or air-fuel mixture is drawn into the

cylinder is called the inlet manifold.

Gudgeon Pin

It forms the link between the small end of the connecting rod

and the piston.

Exhaust Manifold

The pipe that connects the exhaust system to the exhaust valve

of the engine and through which the products of combustion escape into the

atmosphere is called the exhaust manifold.

Inlet and Exhaust Valves

Valves are commonly mushroom shaped poppet type. They are

provided either on the cylinder head or on the side of the cylinder for

regulating the charge coming into the cylinder (inlet valve) and for

discharging the products of combustion (exhaust valve) from the cylinder.

Connecting Rod

It interconnects the piston and the crankshaft and transmits

the gas forces from the piston to the crankshaft. The two ends of the

connecting rod are called as small end and the big end. Small end is connected

to the piston by gudgeon pin and the big end is connected to the crankshaft by

crankpin.

Crankshaft

It converts the reciprocating motion of the piston into useful

rotary motion of the output shaft. In the crankshaft of a single cylinder

engine there is pair of crank arms and balance weights. The balance weights are

provided for static and dynamic balancing of the rotating system. The

crankshaft is enclosed in a crankcase.

Piston Rings

Piston rings, fitted into the slots around the piston, provide

a tight seal between the piston and the cylinder wall thus preventing leakage

of combustion gases

Camshaft

The camshaft and its associated parts control the opening and

closing of the two valves. The associated parts are push rods, rocker arms,

valve springs and tappets. This shaft also provides the drive to the ignition

system. The camshaft is driven by the crankshaft through timing gears.

Cams

These are made as integral parts of the camshaft and

are designed in such a way to open the valves at the correct timing and to keep

them open for the necessary duration.

Fly Wheel

The net torque imparted to the crankshaft during one complete

cycle of operation of the engine fluctuates causing a change in the angular

velocity of the shaft. In order to achieve a uniform torque an inertia mass

in the form of a wheel is attached to the output shaft and this wheel is called

the flywheel.

Basic Parts of the Gasoline

Engine:

Basic

Parts of the Gasoline Engine are listed below;

·

Cylinder block

·

Piston

·

Piston rings

·

Piston pin

·

Connecting rod

·

Crankshaft

·

Cylinder head

·

Intake valve

·

Exhaust valve

·

Camshaft

·

Timing gears

·

Spark plug

Cylinder Block:

Cylinder

Block Basic frame of gasoline engine. Contains the cylinder.

Piston:

Piston

A sliding plug that harnesses the force of the burning gases in the cylinder.

Piston Rings:

Piston

rings seal the compression gases above the piston keep the oil below the piston

rings.

Piston Pins:

Piston Pins Also known as the wrist pin, it connects the

piston to the small end of the connecting rod. It transfers the force and allows

the rod to swing back and forth.

Connecting Rod:

Connecting

Rod Connects the piston and piston pin to the crankshaft.

Crankshaft:

Crankshaft Along the the piston pin and connecting rod it

converts the up and down motion (reciprocating) of the engine to spinning

(rotary) motion.

Flywheel:

Flywheel

Carries the inertia when there is no power stroke.

Cylinder Head:

Cylinder Head Forms the top of the combustion chamber.

Contains the valves, the passageways for the fuel mixture to move in and out of

the engine.

Intake and Exhaust Valves:

Intake

and Exhaust Valves Doorway that lets the gases in and out of the engine.

Camshaft:

Camshaft Through the use of an eccentric the cam lobes push

the valves open. The valve springs close them.

Timing Gears:

Timing Gears These gears drive the camshaft from the

crankshaft.

Why not diesel engines are not

preferred in commercial ?:

1.

Diesel engines, because they have much higher

compression ratios (20:1 for a typical diesel vs. 8:1 for a typical gasoline

engine), tend to be heavier than an equivalent gasoline engine.

2.

Diesel engines also tend to be more expensive.

3.

Diesel engines, because of the weight and

compression ratio, tend to have lower maximum RPM ranges than gasoline engines

.This makes diesel engines high torque rather than high horsepower, and that

tends to make diesel cars slow in terms of acceleration.

4.

Diesel engines must be fuel injected, and in the

past fuel injection was expensive and less reliable

5.

Diesel engines tend to produce more smoke.

6.

Diesel engines are harder to start in cold

weather, and if they contain glow plugs, diesel engines can require you to wait

before starting the engine so the glow plugs can heat up.

7.

Diesel engines are much noisier and tend to

vibrate.

8.

Diesel fuel is less readily available than

gasoline

Advantages diesel engines:

The two things working in favor of diesel engines are better

fuel economy and longer engine life. Both of these advantages mean that, over

the life of the engine, you will tend to save money with a diesel.

However, you also have to take the initial high cost of the

engine into account. You have to own and operate a diesel engine for a fairly

long time before the fuel economy overcomes the increased purchase price of the

engine.

The equation works great in a big diesel tractor-trailer rig

that is running 400 miles every day, but it is not nearly so beneficial in a

passenger car.

Related Topics