Textiles and Dress Designing - Belts and Types of Belts | 12th Textiles and Dress Designing : Chapter 9 : Fashion Accessory and Ornamentation - Belts, Bows, Smocking and Traditional Embroidery

Chapter: 12th Textiles and Dress Designing : Chapter 9 : Fashion Accessory and Ornamentation - Belts, Bows, Smocking and Traditional Embroidery

Belts and Types of Belts

Belts

Belts are flexible band or strap of material worn round the waist

over the garment usually to conceal the waist joint of bodice and skirt. The

styles of belts go well with the design of the dress. Suitable material or

contrasting colours can be used effectively to emphasise the belt. Belts enhance

the look of the wearer. Selection of the size, shape, colour and type of the

belt may vary from individual to individual. Belts may be made soft or stiff,

narrow or wide, plain or intricate, depending upon the garment and the fashion

trend. Stiffening used as a facing or interfacing keeps the belt in shape and

gives it a tailored effect. Muslin, belting, cross grain ribbon or leather may

be applied. The belt is mostly fastened with a covered buckle or a novelty

buckle. Faced, interfaced tie belts and skirt bands are cut in lengthwise

grain, while sash belts are cut on the bias direction. Belts made from the same

material of the garment serve both useful and decorative.

A. Types of Belts

1.

Soft belt

2.

Stiffened belt

3.

Shaped belt

4.

Interfaced belt

5.

Belt with backing

6.

Contour belt

7. Inner belt

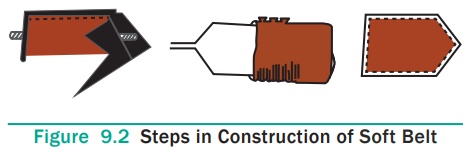

1. Soft Belt

Soft waist belt is a fashion belt made of soft materials. These

belts are used by woman folk along with western wear. Soft belts cinch the

waist of the hour glass type figure and is ideal to wear over the over sized

garments. These belts are adjustable, stylish and suitable for casual and

formal wears.

Method of Construction

·

Take two lengths of belt pieces and a tape.

·

Tack tape length to the right side of pointed end of the belt.

·

Fix two sides of the belt in position right sides facing each

other

·

Machine around the belt starting from square edge

·

Leave a small length unstitched near the square edge in order to

pull the belt inside out

·

Trim the pointed edge gently to avoid bulkiness when turned

·

Drag one end of the tape and pull the belt inside out

·

Remove the temporary tacking used to fix tape

·

Press the unstitched seam edges to the wrong side at the square

edge and press neatly

·

Finish the square edges with slip stitch and complete the belt.

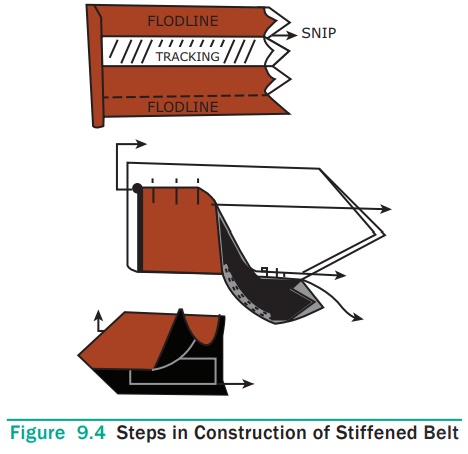

2. Stiffened Belt

The stiffened belt is one of the stable belts. These belts are cut

on grain and are stiffened with interfacings. Stiffening material used in belt

holds the belt in place. The stiffening materials are chosen based on the type

of material used for the belt. Width of these belts is even and matched with

garment styles.

Method of Construction

·

Take required length of material with seam allowance

·

Cut the stiffening material to the finished width of the belt

·

Mark fitting lines on the wrong side of the belt

·

Place the stiffening piece to the fitting lines and sew

·

Fold the seam allowance along top and bottom edges

·

Fold the seam allowance of the square edges and press

·

Trim the turnings of the sharp end on the wrong side of the

fitting lines for flatness

·

Pin and tack this in place, and slip-hem the bend into position

·

Machine stitch in flat rows on the right side of the belt

·

Fix a buckle to the square end if required.

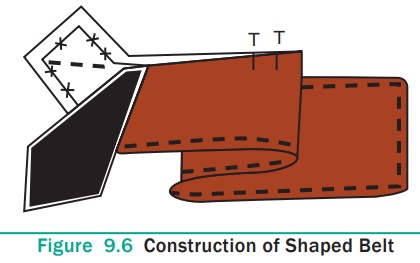

3. Shaped Belt

The belts are shaped to create variety and beauty. Belt shapes are

designed to match various garment styles and the wearer.

Method of Construction

·

To make shaped belt, first cut the interfacing of pre-shrunk

canvas

·

Use suitable weight of interfacing for stiffening the belt

·

Pin the interface to the outer belt fabric

·

Pin, rotate and baste the fabric edges over the interfacing

·

Clip the curved edges if the belt is shaped

·

Fold edges of the lining to the belt and stitch

·

The belt may be edge stitched from the right side if needed

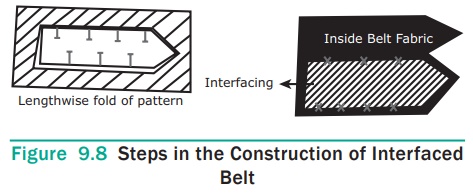

4. Interfaced Belt

The interfaced belt is the softest belt used for comfort. Folding

over and becoming rope-like when worn are the disadvantages of this style of

belt. From the fashion point of view, it is not the most desirable belt as many

prefer stiff belts. One must be careful while selecting washable belts.

Method of Construction

·

Fold the belt pattern in half-lengthwise

·

Cut the interfacing fabric exactly to the finished width of the

belt

·

Pin the interfacing to the wrong side of the belt

·

Cut the belt edges evenly

·

Catch stitch the long edge of interfacing to the center line of

the belt

·

Then fold the belt, half- lengthwise with right sides together and

stitch along the edges of the belt to the pointed end.

·

Cut off the corners and turn the belts right side out

·

Turn the seam allowances and baste the finished edges

·

Top stitch near the long edges if needed.

·

Attach buckles and finish.

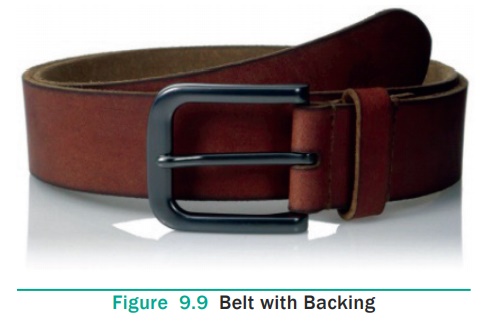

5. Belt with Backing

Belt with backing is a type of belt that gives a professional

belt. This belt is constructed with backing material. This type of belt does

not fold since it is backed with supportive backing material. Pre-shrinking has

to be done if soft and ribbon like materials are used.

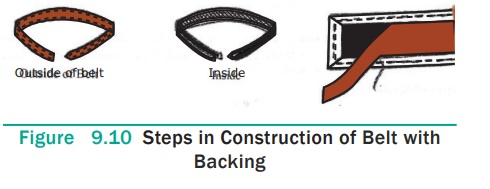

Method of Construction

·

Cut a piece of backing material to the necessary length with an

overlap of about 7 inches.

·

Carefully shape one end of the belting as desired.

·

Cut matching fabric in lengthwise grain for one inch wider and 1”

longer than the belting

·

Lap one edge of the belt fabric 1/2 inch over the belting and

baste in place firmly.

·

Hold the belt in a curved position

·

Cover the fabric around the belting and keep it tight

·

Pin it in place over the belting and sew the remaining edge in

place

·

Machine stitch ¼ inch away from the outer edges of the belt with

longer stitches

·

This belt is also made broader as waistbands and is suitable for

many skirts.

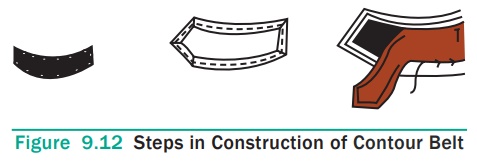

6. Contour Belt

The contour belt is shaped to the body. It will hold the waistline

perfectly and rest at the back. It is usually wider at the back and narrower at

the front. The wider belts prominently show the contours or curved lines of the

body. Narrow belts do not highlight the contours. This belt takes more time to

make than the straight belt with belting as a backing.

·

It is constructed by cutting an interfacing, facing and the stiff,

in a cross grain to hold the belt correctly in position.

·

Take the required length of belt material and fold into two

·

Mark the on fold line as centre back

·

From centre back to centre front mark side seam line point

·

Mark a point between centre back and side seam line

·

Also mark a point between centre front and side seam line

·

Cut through the marked points and overlap the top side of the belt

to properly fit the contour belt to the figure

·

The belt is finished in a corresponding way as interfaced belts

·

This belt is also made broader as waistbands.

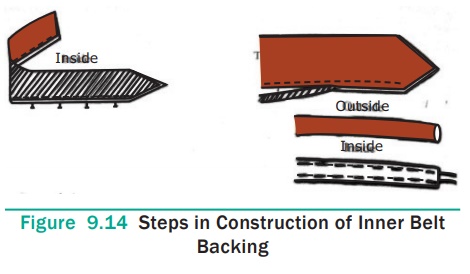

7. Inner Belt Backing

Usually, the inner material is used for extra stiffness. The cross

grain ribbon is cut and finished at the inner part of waistband which holds the

skirt. The natural shape of the human figure is enriched by this belt.

Method of Construction

·

Take required length of material with seam allowance

·

Cut the stiffening material to the finished width of the belt

·

Place the stiffening material in between belt material

·

Fold the seam allowance along top and bottom edges

·

Fold the seam allowance of the square edges on the wrong side and

press

·

Machine stitch in flat rows on the right side of the belt.

B. Summary for Belts

Belts play an essential role in garments. It is an important

fashion accessory worn with garments. There are different types of belt

available in the market. Each and every type is designed for a specific

purpose. Belts are constructed with numerous materials. Every belt is finished

with buckle and eyelets. Bows are sometimes attached for design effect. Belts

have its unique applications in its own way. They could be varied according to

the pattern, purpose and the type of wearer.

Related Topics