Chapter: Pharmaceutical Drug Analysis: Amperometric Methods

Amperometric Methods: Instrumentation

INSTRUMENTATION

The amperometric titrations can be accomplished by any

one of the three methods, namely :

(i)

Amperometric titrations with the dropping mercury electrode,

(ii)

Amperometric titrations with a rotating platinum microelectrode, and

(iii)

Amperometric titrations with twin-polarized microelectrodes (or Biamperometric Titrations or Dead-stop-end-point method).

These three

techniques will be discussed in the sections that follow.

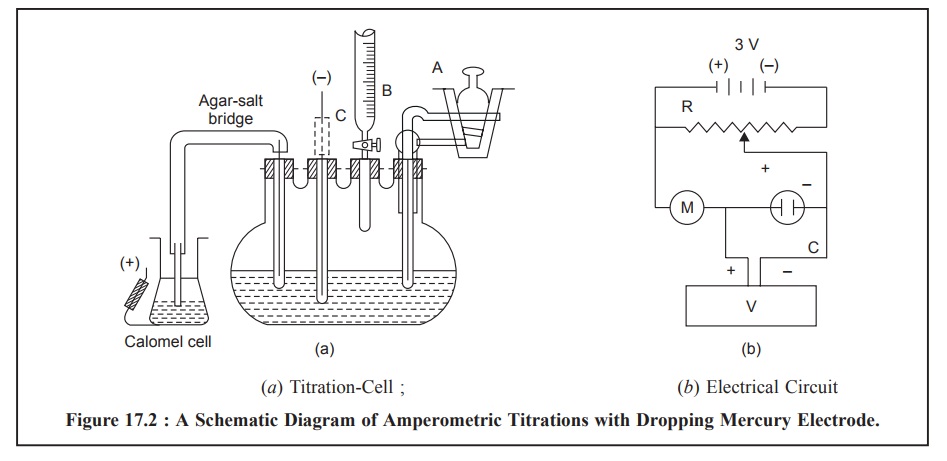

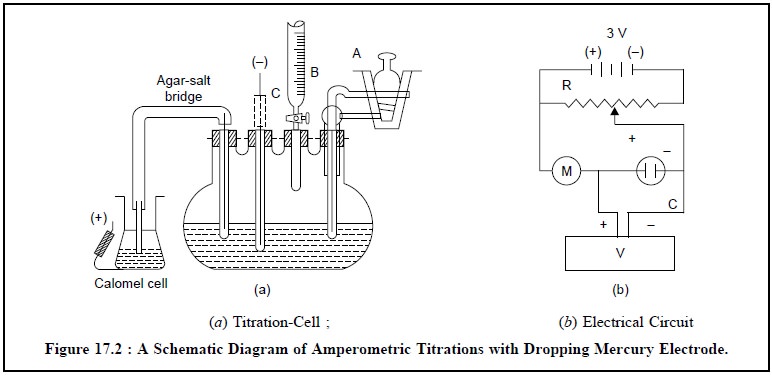

1. AMPEROMETRIC TITRATIONS WITH THE DROPPING MERCURY ELECTRODE

Figure 17.2 (a)

and (b) illustrates the schematic

diagram of amperometric titrations with the dropping mercury electrode having a

titration-cell and an electric circuit respectively.

The titration-cell Figure 17.2 (a) essentially comprises of a pyrex 100-ml, four-necked,

flat-bottomed flask. A semimicro burette (B) (graduated in 0.01 ml), a 2-way

gas-inlet tube (A) to enable N2 to pass either through the solution

or simply over its surface, a dropping mercury electrode (C) and an

agar-potassium salt-bridge* are duly fitted into the four necks with the help

of air-tight rubber stoppers.

The electrical circuit, Figure 17.2 (b), consists of two 1.5 V dry cells that provides a voltage applied

to the above titration cell. It is duly controlled and monitored by the

potential divider (R) and is conveniently measured with the help of a digital

voltmeter (V). Finally, the current flowing through the circuit may be read out

on the micro-ammeter (M) installed.

The following steps may be carried out in a sequential

manner for an amperometric titration, namely :

·

A known volume of the solution under investigation is

introduced in the titration cell,

·

The apparatus is assembled and electrical connections are

duly completed with dropping mercury electrode (C) as cathode and saturated

calomel half-cell as anode,

·

A slow stream of pure analytical grade N2 –

gas is bubbled through the solution for 15 minutes to get rid of dissolved O2

completely,

·

Applied voltage is adjusted to the desired value, and the

initial diffusion current (Id) is noted carefully,

·

A known volume of the reagent is introduced from the

semimicro burette (B), while N2 is again bubbled through the

solution for about 2 minutes to ensure thorough mixing as well as complete

elimination of traces of O2 from the added liquid,

·

The flow of N2 gas through the solution is

stopped, but is continued to be passed over the surface of the solution gently

so as to maintain an O2 free inert atmosphere in the reaction

vessel,

·

The current (µA) and microburette readings

are recorded simultaneously, and

·

Finally, the said procedure is repeated until sufficient

readings have been obtained to allow the equivalence point to be determined as

the intersection of the two linear portions of the graph thus achieved.

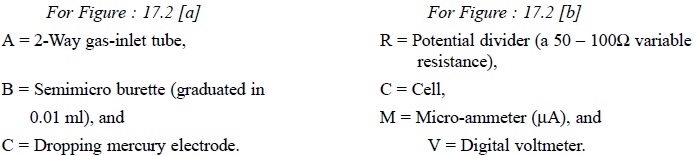

2. AMPEROMETRIC TITRATIONS WITH A ROTATING PLATINUM MICROELECTRODE

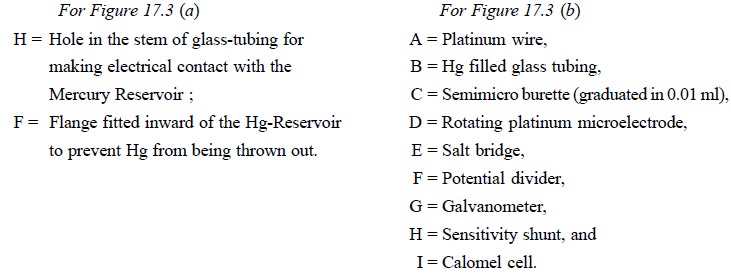

The rotating platinum microelectrode was first introduced

by Laitinen and Kolthoff in 1941. Figure 17.3 (a) depicts a simple rotating platinum microelectrode which is made

out from an usual standard ‘mer-cury seal’. A platinum wire (length : 5.0 mm ;

diameter : 0.5 mm) protrudes from the lower end wall of a 21 cm long 6 mm glass

tubing, which is bent at an angle of 90°. There are holes (H) in the stem of

the mercury reservoir for making electrical contact with it. The mercury

reservoir is provided with a flange fitted inward to prevent Hg from being

thrown out.

Figure 17.3 (b)

illustrates the electric circuit. The electrical connection is duly done to the

electrode by means of a strong amalgamated Cu-wire passing through the glass

tubing to the lower end of the Hg covering the sealed-in platinum wire ; the

upper end of which passes through a small hole made in the stem of the stirrer

and dips well into the Hg present in the Hg seal. Subsequently, a wire from the

Hg seal is connected to the source of applied voltage. The glass tubing serves

as the stem of the electrode that is rotated at a constant speed of 600 rpm.

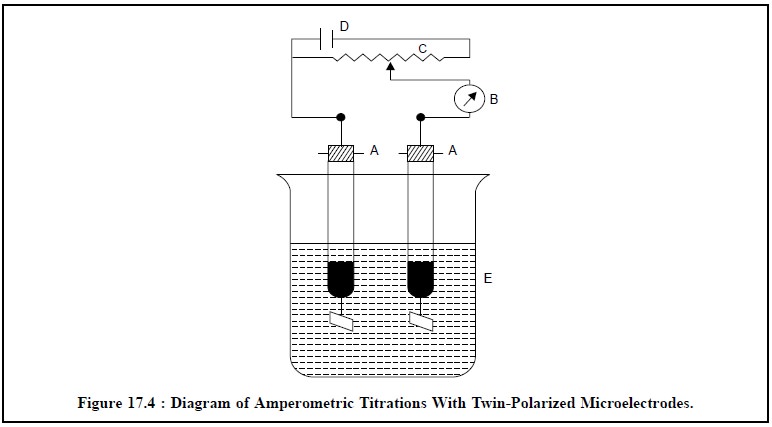

3. AMPEROMETRIC TITRATIONS WITH TWIN-POLARIZED MICROELECTRODES (BIAMPEROMETRIC TITRATIONS OR DEAD-STOP-END-POINT METHOD)

Dead-stop-end-point method was first introduced by Foulk

and Bawden* in 1926. Evidently, this particular

technique is a modification of the classical amperometric titration. This

technique is specifically applicable to only such systems where the phenomenon

of oxidation-reduction exists both before as well as after the equivalence

point has been duly accomplished.

It essentially makes use of two identical, stationary

microelectrodes immersed in a well stirred solu-tion of the sample. A small

potential ranging between these electrodes ; and the resulting current is

measured subsequently as a function of the volume of reagent added. The

end-point is distinctly characterized by a sudden current rise from zero or a

decrease in the current to zero or a minimum at zero in a V-shaped curve.

Though this technique was first used in 1926, but it

received its due recognition only around 1950**. F

igure 17.4 represents a simple diagram of an amperometric

titration assembly with twin-polarized microelectrodes.

The various components are as follows :

A, A = Twin-polarized Platinum microelectrodes,

B= Micro-ammeter (µA),

C= 500 Ω,

0.5 watt potentiometer,

D = 3-Volt dry torch cell or a 2-volt accumulator

E = Reaction vessel.

The potentiometer is adjusted in such a fashion that

there is a distinct potential drop of about 80 to 100 millivolts between the

two platinum electrodes.

Related Topics