Chapter: Pharmaceutical Biotechnology: Fundamentals and Applications : Growth Hormones

Protein Manufacture, Formulation and Stability- Growth Hormones

PROTEIN MANUFACTURE, FORMULATION AND STABILITY

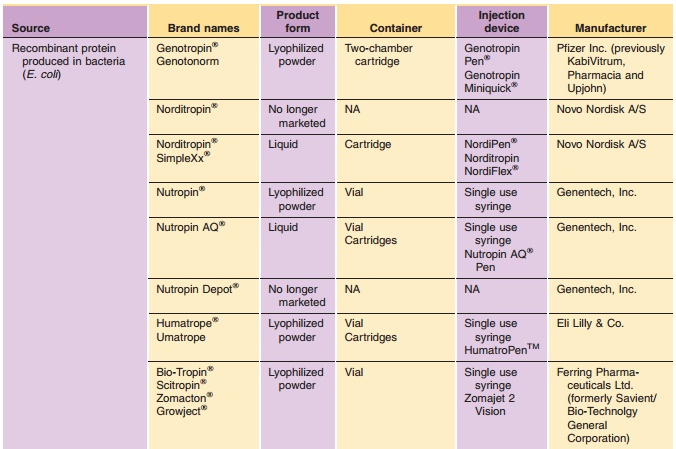

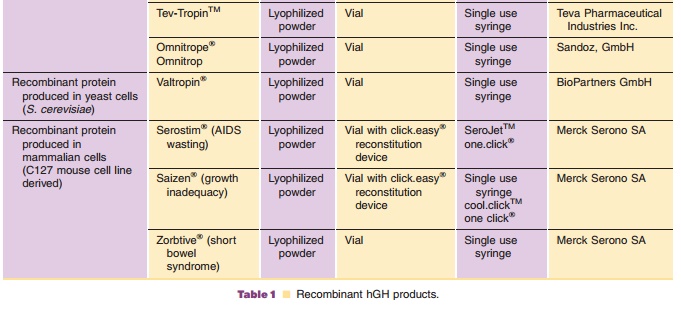

Commercially available hGH preparations are sum-marized in Table 1. All

recombinant growth hor-mones except Serostim / Saizen / Zorbtive are produced

in bacteria or yeast (E. coli, S. cerevisiae). Serostim / Saizen / Zorbtive are

produced in mammalian cells (C127 mouse cells). Growth hor-mone produced in E.

coli may contain an N-terminal methionine residue. Natural sequence rhGH is

produced either by enzymatic cleavage of the methionine during the purification

procedure or by periplasmic secretion of rhGH into refractile bodies. The rhGH

is then released from the refractile bodies by osmotic shock and the protein

recovered and purified. rhGH synthesized in mammalian cells is transported

across the endoplasmic reticulum and secreted directly into the culture medium

from which it is recovered and purified.

Historically, the potency of hGH products was expressed in international

units per mg (IU/mg). The initial standard, established in 1982 for pit-hGH

preparations, was 2 IU/mg. The standard for rhGH products was 2.6 IU/mg until

September 1994. The current WHO standard, established in September 1994, is 3.0

IU/mg. Dosages are usually expressed as IU/kg or IU/m2 in Europe and Japan and as mg/kg

in the United States. However, the use of IU dosages is no longer necessary due

to the high level of purity and consistent potency of recombinant hGH products.

All current rhGH products are available as lyophilized or liquid

preparations. Lyophilized for-mulations usually include 5 or 10 mg of protein

in a glycine and mannitol or sucrose-containing phos-phate buffer excipient.

The materials are usually reconstituted with sterile water for injection for

single use or with bacteriostatic water or bacteriostatic saline for multiple

injection use. Liquid formulations of rhGH (Nutropin AQ , Norditropin ,

SimpleXx ) contain mannitol or sodium chloride, histidine or citrate buffer,

poloxamer 188 or polysorbate 20 and phenol. Product stability has been very

good with shelf lives of approximately 2 years at 2 C to 8 C. A long-acting

dosage form of rhGH (Nutropin Depot ) was available from 1999 until 2004.

Nutropin Depot contained micronized particles of rhGH embedded in

biocompatible, biodegradable polylactide-coglycolide (PLGA) microspheres.

Omnitrope /Omnitrop (US/EU) and Valtropin (EU only), lyophilized rhGH preparations,

were approved for marketing as the first “biosimilar” rhGH products in 2006.

Related Topics