Chapter: Automation, Production Systems, and Computer Integrated Manufacturing : Introduction

Manual Labor in Production Systems

MANUAL LABOR IN PRODUCTION SYSTEMS

Is there

a place for manual labor in the modern production system? The answer is

certainly yes. Even in a highly automated production system, humans are still a

necessary component of the manufacturing enterprise. For the foreseeable

future, people will be required to manage and maintain the plant, even in those

cases where they do not participate directly in its manufacturing operations.

Let us separate our discussion of the labor issue into two parts, corresponding

to our previous distinction between facilities and manufacturing support: (1)

manual labor in factory operations and (2) labor in the manufacturing support

systems.

1.

Manual Labor in Factory Operations

There is

no denying that the longterm trend in manufacturing is toward greater use of

automated machines to substitute for manual labor. This has been true

throughout human history, and there is every reason to believe the trend will

continue. It has been made possible by applying advances in technology to

factory operations. In parallel, and sometimes in conflict, with this

technologically driven trend are issues of economics that continue to find

reasons for employing manual labor in manufacturing operations.

Certainly

one of the current economic realities in the world is that there are countries

whose average hourly wage rates are sufficiently low that most automation

projects are im possible to justify strictly on the basis of cost reduction. At

time of writing, these countries include Mexico, China, and most of the

countries of Southeast Asia. With the recent passage of the North American Free

Trade Agreement (NAFTA), the North American continent has become one large

labor pool. Within this pool, Mexico’s labor rate is an order of magnitude less

than that in the United States. For U.S. corporate executives making decisions

on a factory location or the outsourcing of work, this is an economic reality

that must be reckoned with.

In addition to the labor rate issue, there are other reasons, ultimately

based on economics, that make the use of manual labor a feasible alternative to

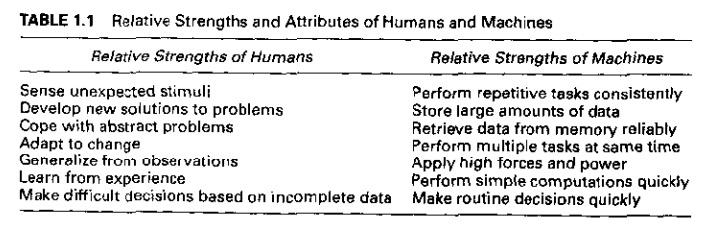

automation. Humans possess certain attributes that give them an advantage over

machines in certain situations and certain kinds of tasks. Table 1.1 lists the

relative strengths and attributes of humans and machines. A number of situations

can be listed in which manual labor is usually preferred over automation:

• Task is too technological difficulty to automated. Certain

tasks are very difficult (either technologically or economically) to automate.

Reasons for the difficulty include:

(1) problems

with physical access to the work location, (2) adjustments required in the

task, (3) manual dexterity requirements, and (3) demands on handeye

coordination. Manual labor is used to perform the tasks in these cases.

Examples include automobile final assembly lines where many final trim

operations are accomplished by human workers.

• Short product life cycle. If the

product must be designed and introduced in a short period of time to meet a nearterm window of opportunity in the

marketplace, or if the product is anticipated to be on the market for a

relatively short period, then a manufacturing method designed around manual

labor allows for a much faster product launch than does an automated

method.Tooling for manual production can be fabricated in much less time and at

much lower cost than comparable automation tooling.

• Customized product. If the

customer requires a oneofakind item with unique features, manual labor may have

the advantage as the appropriate production resource because of its versatility

and adaptability. Humans are more flexible than any automated machine.

• To cope with ups and downs in demand. Changes

in demand for a product necessitate changes

in production output levels. Such changes are more easily made when manual

labor is used as the means of production. An automated manufacturing system has

a fixed cost associated with its investment. If output is reduced, that fixed

cost must be spread over fewer units, driving up the unit cost of the product.

On the other hand,

an

automated system has an ultimate upper limit on its output capacity. It cannot

produce more than its rated capacity. By contrast, manual labor can be added or

reduced as needed to meet demand, and the associated cost of the resource is in

direct proportion to its usage. Manual labor can be used to augment the output

of an existing automated system during those periods when demand exceeds the

capacity of the automated system.

• To reduce risk of product failure. A

company introducing a new product to the market never knows for sure what the

ultimate success of that product will be. Some products will have long life

cycles, while others will be on the market for relatively short lives. The use

of manual labor as the productive resource at the beginning of the product’s

life reduces the company’s risk of losing a significant investment in

automation if the product fails to achieve a long market life. In Section

1.5.3, we discuss an automation migration strategy that is suitable for

introducing a new product.

2. Labor

in Manufacturing Support Systems

In

manufacturing support functions, many of the routine manual and clerical tasks

can be automated using computer systems. Certain production planning activities

are better accomplished by computer than by clerks. Material requirements

planning (MRP, Section 26.2) is an example: In material requirements planning,

order releases are generated for component parts and raw materials based on the

master production schedule for final products. This requires a massive amount

of data processing that is best suited to computer automation. Many commercial

software packages are available to perform MRP. With few exceptions, companies

that need to accomplish MRP rely on the computer. Humans are still required to

interpret and implement the output of these MRP computations and to otherwise

manage the production planning function.

In modern production systems, the computer is used as an aid in

performing virtually all manufacturing support activities. Computeraided design

systems are used in product design. The human designer is still required to do

the creative work. The CAD system is a tool that assists and amplifies the

designer’s creative talents. Computeraided process planning systems are used by

manufacturing engineers to plan the production methods and routings. In these

examples, humans are integral components in the operation of the manufacturing

support functions, and the computeraided systems are tools to increase

productivity and improve quality. CAD and CAM systems rarely operate completely

in automatic mode.

It is very unlikely that humans will never be needed in manufacturing

support systems, no matter how automated the systems are. People will be needed

to do the decision making, learning, engineering, evaluating, managing, and

other functions for which humans are much better suited than are machines,

according to Table 1.1.

Even if all of the manufacturing systems in the factory are automated,

there will still be a need for the following kinds of work to be performed:

• Equipment maintenance. Skilled

technicians will be required to maintain and repair the automated systems in the factory when these systems break down.To

improve the reliability of the automated systems, preventive maintenance will

have to be carried out.

Programming and computer

operation. There will be a continual demand to upgrade software, install new versions of software packages, and execute

the programs. It is anticipated that much of the routine process planning,

numerical control part pro gramming, and robot programming may be highly

automated using artificial intelligence in the future.

• Engineering project work. The

computerautomated and integrated factory is likely never to be finished. There will be a continual need to upgrade

production machines, design tooling, and undertake continuous improvement

projects. These activities require the skills of engineers working in the

factory.

• Plant management. Someone must be responsible for

running the factory. There will be a

limited staff of professional managers and engineers who are responsible for

plant operations. There is likely to be an increased emphasis on managers’

technical skills rather than in traditional factory management positions, where

the emphasis is on personnel skills.

Related Topics